The most critical precaution when installing PTFE O-rings is to avoid stretching or nicking the material. Unlike flexible elastomers, PTFE is a rigid plastic with minimal elasticity, meaning any deformation caused by forcing it over sharp threads or edges will be permanent and will compromise the seal. Successful installation requires meticulous preparation of the hardware and careful handling of the O-ring itself.

The core challenge with PTFE O-rings is their lack of "memory" or elasticity. You must treat the installation not as stretching a rubber band into place, but as precisely fitting a rigid, sensitive component that will not forgive nicks, gouges, or over-stretching.

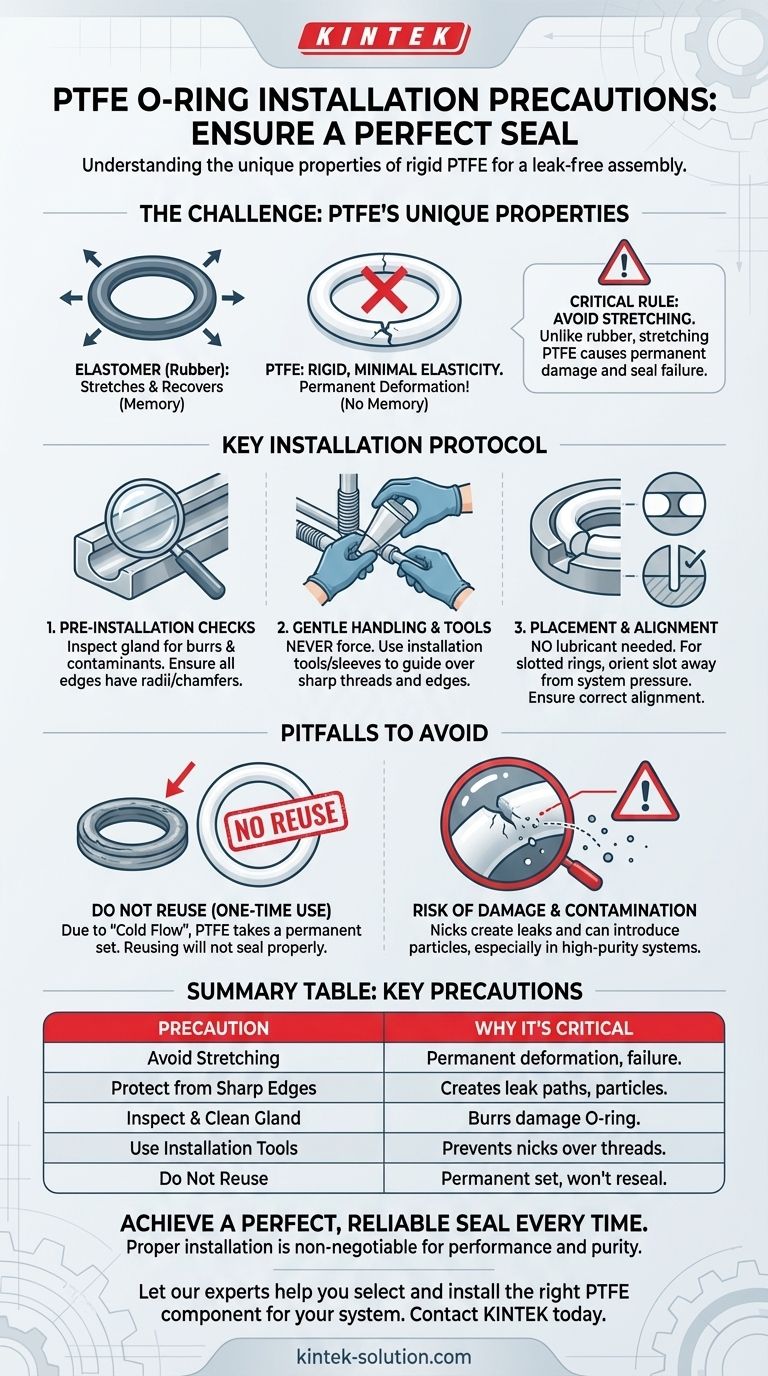

The Challenge: Understanding PTFE's Unique Properties

To ensure a successful seal, you must first respect the material. PTFE (Polytetrafluoroethylene) behaves fundamentally differently from common elastomers like nitrile or Viton, and these differences dictate the entire installation procedure.

Low Elasticity (The "No-Stretch" Rule)

PTFE has very poor elastic memory. While a rubber O-ring can be stretched significantly and will snap back to its original shape, stretching a PTFE O-ring will permanently deform it.

This lack of recovery means it will not provide the necessary compressive force (squeeze) to create a reliable seal if it has been overstretched during assembly.

Cold Flow and Permanent Deformation

Under compressive load, PTFE is subject to cold flow, a phenomenon where the material slowly deforms over time. This is why PTFE O-rings conform well to gland surfaces to create a tight seal.

However, this also means they take a permanent set. Once compressed, they will not return to their original dimensions, making them a one-time-use component.

Susceptibility to Physical Damage

PTFE is a relatively soft material. It can be easily nicked, scratched, or gouged by sharp corners, threads, or burrs in the hardware gland.

Any surface imperfection on the O-ring creates a potential leak path, immediately compromising the integrity of the seal.

The Correct Installation Protocol

A successful installation is a methodical process focused on preparation and gentle handling.

Pre-Installation Checks

Before you even touch the O-ring, inspect the hardware. The gland (the groove where the O-ring sits) must be completely clean and free of burrs, metal swarf, or any other contaminants.

Ensure all leading edges and corners the O-ring must pass over have radii or chamfers to prevent cutting.

Handling the O-ring

Never force or stretch the O-ring into place. For installations over sharp areas like threads, use installation tools or protective sleeves to guide the ring and prevent contact.

Handle the O-ring itself with care, ensuring it is not nicked or contaminated with weld spatter, paint, or other debris prior to assembly.

Placement and Lubrication

PTFE's naturally low coefficient of friction means no grease or lubrication is needed for installation. The material is inherently slippery, which aids in a smooth placement.

If you are using a specialized slotted PTFE O-ring, ensure the slot is oriented to face away from the system pressure. This design helps compensate for low elasticity, but only when installed correctly.

Understanding the Trade-offs and Pitfalls

Ignoring the unique properties of PTFE leads to immediate or eventual seal failure. Awareness of these common pitfalls is crucial.

One-Time Use is Not a Suggestion

Attempting to reuse a PTFE O-ring is a primary cause of failure. Due to cold flow, a used O-ring has already permanently deformed to its first installation groove. It will not properly seal a second time.

The Risk of System Contamination

If a PTFE O-ring is scraped or gouged during installation, small particles can break off and contaminate the system. This is especially critical in high-purity applications like semiconductor or food processing.

This is also a risk with PTFE-coated O-rings, where the coating can flake off and introduce foreign material into the process fluid.

Incorrect Compression and Alignment

Just as with a gasket, applying incorrect or uneven force can cause the O-ring to extrude into gaps or fail to seal properly. Ensure components are aligned correctly and that any bolts are tightened in a proper sequence to apply even pressure.

Making the Right Choice for Your Goal

Your installation technique must match the demands of your application to achieve a reliable, long-lasting seal.

- If your primary focus is static chemical sealing: Meticulously prepare the gland surfaces, ensure there are no sharp edges, and gently place the O-ring without any stretching.

- If you are considering a dynamic application: Proceed with extreme caution. Pure PTFE has poor wear resistance; use it only in very low-speed, low-pressure dynamic seals and be aware that its life will be limited.

- If your primary focus is system purity: Absolute cleanliness is paramount. Inspect the gland and the O-ring for any contaminants and use guide tools to prevent any shaving of the material during assembly.

Ultimately, successful sealing with PTFE depends on accommodating the material's properties, not fighting them.

Summary Table:

| Key Precaution | Why It's Critical |

|---|---|

| Avoid Stretching | PTFE has low elasticity; stretching causes permanent deformation and seal failure. |

| Protect from Sharp Edges | PTFE is soft and easily nicked or gouged, creating leak paths. |

| Inspect and Clean Gland | Burrs or contaminants can damage the O-ring and compromise the seal. |

| Use Installation Tools | Guides and sleeves prevent damage when passing over threads or edges. |

| Do Not Reuse | PTFE O-rings cold flow and take a permanent set; they are one-time-use. |

Achieve a perfect, reliable seal every time.

PTFE O-rings are critical for sealing in the most demanding semiconductor, medical, laboratory, and industrial environments. Proper installation is non-negotiable for performance and purity.

At KINTEK, we don't just supply high-precision PTFE components—we provide the expertise to ensure they work flawlessly in your application. Whether you need standard PTFE seals, liners, and labware or require custom fabrication from prototypes to high-volume orders, our focus on precision manufacturing guarantees a perfect fit and superior performance.

Let our experts help you select and install the right PTFE component for your system. Contact KINTEK today for a consultation.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance