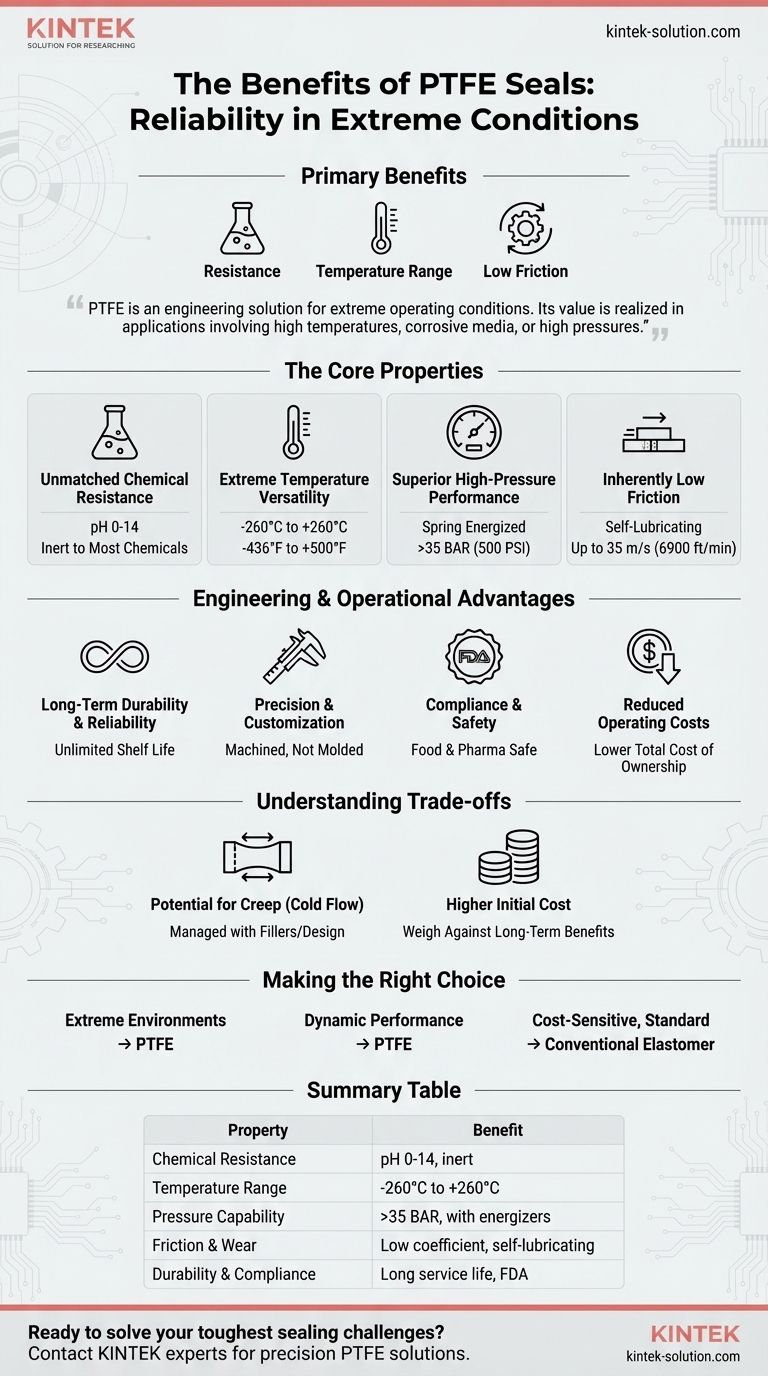

The primary benefits of using PTFE seals are their exceptional resistance to aggressive chemicals, their ability to function across an extremely wide temperature range, and their inherently low friction. This unique combination of properties allows them to provide reliable sealing in demanding industrial applications where conventional elastomer seals would quickly fail.

PTFE is not simply another sealing material; it is an engineering solution for extreme operating conditions. Its value is realized in applications involving high temperatures, corrosive media, or high pressures, where long-term reliability and reduced maintenance are critical.

The Core Properties of PTFE Seals

The advantages of PTFE (Polytetrafluoroethylene) stem from a set of fundamental material characteristics that make it uniquely suited for challenging environments.

Unmatched Chemical Resistance

PTFE is virtually inert to most chemicals, including aggressive acids, solvents, bases, and corrosive fluids. This makes it a default choice for industries like pharmaceuticals, chemical processing, and semiconductor manufacturing.

It can reliably handle fluids across the entire pH range from 0 to 14, a capability that most other sealing materials cannot match.

Extreme Temperature Versatility

PTFE seals maintain their integrity and performance across a vast temperature spectrum. They are effective in cryogenic conditions as low as -260°C (-436°F) and can withstand continuous high temperatures up to +260°C (500°F).

This thermal stability makes them indispensable in aerospace, automotive, and oil and gas applications where temperature fluctuations are common and severe.

Superior High-Pressure Performance

While the base material is strong, PTFE seals are often enhanced with a spring energizer. This internal spring provides a constant radial force, ensuring a tight seal even under immense pressure, often well above 35 BAR (500 PSI).

This design also helps compensate for material wear and thermal expansion, maintaining a consistent sealing force throughout the seal's life.

Inherently Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property significantly reduces wear and frictional heat, improving mechanical efficiency and extending service life.

This is particularly valuable in high-speed dynamic applications, with some designs capable of handling surface speeds of 35 m/s (6900 ft/min) without requiring external lubrication.

The Engineering and Operational Advantages

These core properties translate directly into tangible benefits related to performance, reliability, and cost.

Long-Term Durability and Reliability

Because PTFE is resistant to chemical degradation and environmental stress, it boasts an unlimited shelf life and exceptional durability in service. This resistance to aging ensures predictable, long-term performance.

The material's wear resistance, especially in filled grades, makes it ideal for reciprocating and rotary applications, leading to less frequent maintenance cycles.

Precision and Customization

PTFE seals are typically machined rather than molded. This allows for the creation of highly precise parts with tight tolerances, tailored to the exact requirements of a specific application. Custom designs can optimize performance for unique challenges.

Compliance and Safety

Many PTFE formulations are FDA compliant, making them safe and suitable for use in food processing, beverage, and pharmaceutical equipment where purity is a critical concern.

Reduced Operating Costs

While the initial cost may be higher than standard seals, the extended service life and reduced need for maintenance and lubrication lead to a lower total cost of ownership. Less downtime and fewer seal failures provide a significant operational advantage.

Understanding the Trade-offs and Considerations

No material is a universal solution. To be a trusted advisor means acknowledging the context where PTFE excels and where other factors must be considered.

The Role of Fillers and Energizers

Pure, or "virgin," PTFE has limitations. To enhance specific properties, fillers like carbon, glass fiber, or bronze are often added. These fillers dramatically improve wear resistance, reduce creep, and increase hardness.

Similarly, the spring energizer is not an optional accessory; it is a critical component that provides the necessary sealing force that PTFE's plastic memory alone cannot. Understanding the grade of PTFE and the energizer design is key.

Potential for Creep (Cold Flow)

Unfilled PTFE has a tendency to deform or "creep" over time when under a constant load. While fillers mitigate this, it remains a design consideration. Proper hardware design and gland fill are essential to manage this characteristic and ensure a long-lasting seal.

Higher Initial Cost

PTFE is a high-performance polymer, and its initial purchase price is typically higher than that of common elastomers like Nitrile (NBR) or Viton (FKM). This cost must be weighed against the long-term benefits of durability and reduced downtime in the target application.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material's strengths to your primary operational goal.

- If your primary focus is extreme environments: PTFE is the default choice for applications involving corrosive chemicals or temperatures outside the range of standard elastomers.

- If your primary focus is dynamic performance: The low-friction, self-lubricating nature of PTFE makes it ideal for high-speed rotary or reciprocating machinery where minimizing wear is critical.

- If your primary focus is cost-sensitive, standard conditions: For applications with moderate temperatures, pressures, and non-aggressive media, a conventional elastomer seal may provide a more cost-effective solution.

Ultimately, choosing a PTFE seal is an investment in reliability for your most critical and demanding applications.

Summary Table:

| Property | Benefit |

|---|---|

| Chemical Resistance | Handles pH 0-14; inert to most acids, solvents, and bases. |

| Temperature Range | Performs from -260°C to +260°C (-436°F to +500°F). |

| Pressure Capability | Withstands high pressures, often >35 BAR (500 PSI) with energizers. |

| Friction & Wear | Low coefficient of friction; self-lubricating for long life. |

| Durability & Compliance | Long service life, unlimited shelf life, and FDA-compliant options. |

Ready to solve your toughest sealing challenges with high-performance PTFE components?

KINTEK specializes in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure you get a reliable sealing solution tailored to your specific application's demands, whether it involves extreme temperatures, corrosive chemicals, or high pressures.

Contact our experts today to discuss how our PTFE components can enhance your equipment's reliability and reduce your total cost of ownership.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance