In short, PTFE seals are preferred over traditional rubber seals for their exceptional resilience in extreme operating conditions. Where rubber would degrade and fail, PTFE excels due to its superior resistance to aggressive chemicals, extreme temperatures, and high pressures, combined with a uniquely low coefficient of friction that enhances efficiency and extends service life.

The decision between PTFE and rubber is not about one being universally "better," but about choosing the right material for the job. Rubber is a versatile, cost-effective solution for standard applications, while PTFE is a specialized material engineered for performance and reliability in environments that are too demanding for conventional elastomers.

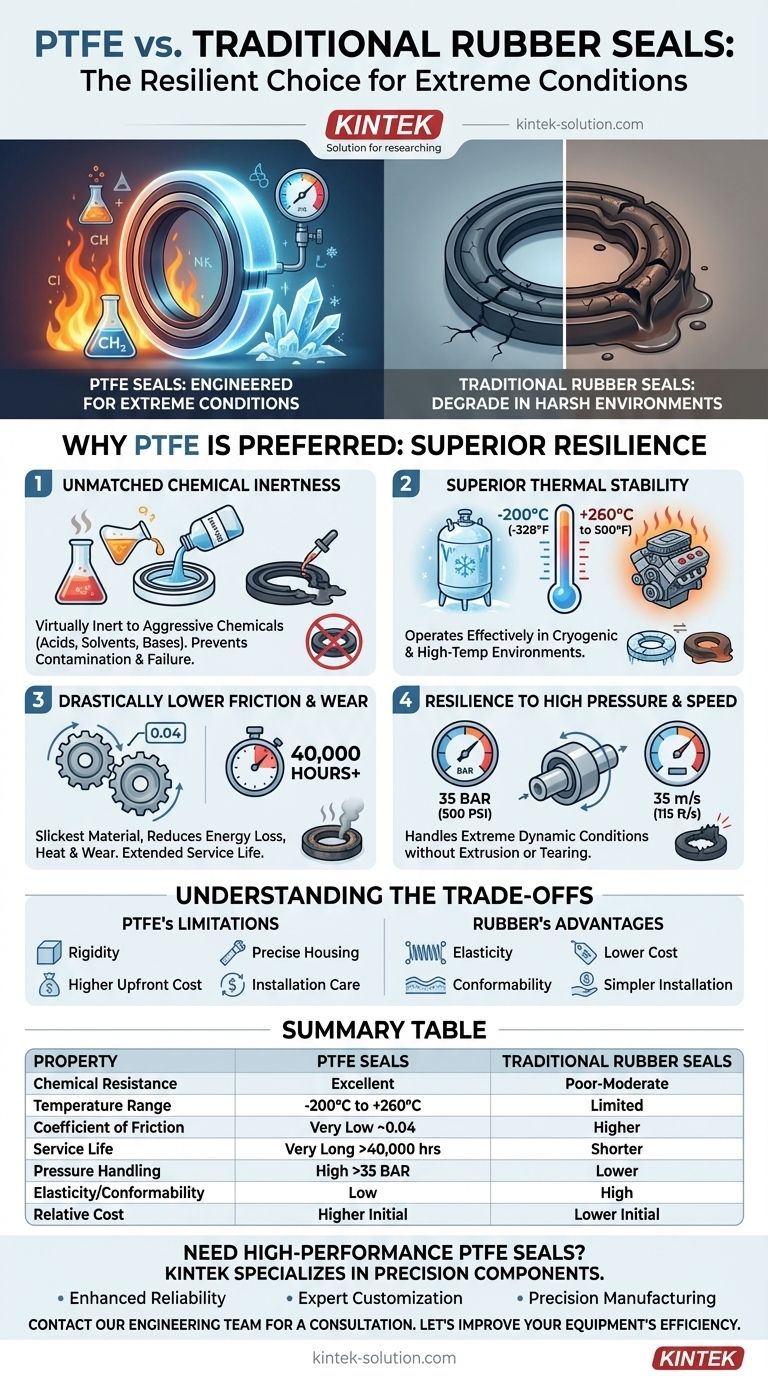

Why PTFE Excels in Harsh Environments

The preference for Polytetrafluoroethylene (PTFE) stems from a unique combination of properties that allow it to function reliably where rubber seals cannot. This makes it indispensable in high-performance industries like aerospace, pharmaceuticals, and automotive engineering.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, including aggressive acids, solvents, and bases. This makes it the default choice for applications in chemical processing, semiconductor manufacturing, and pharmaceuticals, where seal degradation would lead to contamination and failure.

Traditional rubber seals, by contrast, can swell, harden, or dissolve when exposed to incompatible chemicals, resulting in leaks and costly downtime.

Superior Thermal Stability

PTFE seals operate effectively across an exceptionally wide temperature range, with some formulations handling conditions from -200°C to over 260°C (-328°F to 500°F).

This stability makes them ideal for both cryogenic applications and high-temperature environments, such as in automotive engines or oil and gas equipment, where rubber would become brittle or melt.

Drastically Lower Friction and Wear

With a coefficient of friction as low as 0.04, PTFE is one of the slickest materials known. This property significantly reduces energy loss, heat generation, and wear on moving parts.

Its ability to run dry for periods without catastrophic failure provides a critical safety margin in equipment where lubrication might be temporarily lost. This translates to a longer, more reliable service life, often exceeding 40,000 hours.

Resilience to High Pressure and Speed

Engineered PTFE seals are designed to handle extreme dynamic conditions. They can maintain a tight seal at pressures exceeding 35 BAR (500 PSI) and in rotary applications with surface speeds over 35 m/s (115 ft/s).

In high-performance hydraulic and rotary systems, rubber seals would extrude, tear, or overheat under such demanding forces, leading to premature failure.

Understanding the Trade-offs

While PTFE's performance is impressive, it is not the optimal choice for every situation. Objectivity requires acknowledging its trade-offs compared to traditional rubber.

Elasticity and Conformability

Rubber’s inherent elasticity is its primary advantage. It can easily conform to surface imperfections and provides excellent sealing with minimal compressive force, making it ideal for many static applications.

PTFE is a much more rigid material. While this rigidity provides dimensional stability at high pressures, it means PTFE seals require more precise housing finishes and are less forgiving of surface irregularities.

Installation and Cost

For standard, non-demanding applications, rubber seals are generally less expensive and simpler to install. Their flexibility allows them to be stretched and fitted easily.

PTFE seals often have a higher upfront cost and may require more care during installation to avoid damaging the sealing lip. However, this initial investment is frequently justified by reduced maintenance and a longer operational lifespan in the harsh environments they are designed for.

Making the Right Choice for Your Application

Selecting the correct seal material is critical to ensuring the reliability and efficiency of your equipment. The decision should be driven entirely by the specific demands of the operating environment.

- If your primary focus is performance under extreme conditions (high temperatures, aggressive chemicals, high pressures, or high speeds), PTFE is the necessary choice for long-term reliability.

- If your primary focus is a cost-effective solution for a standard application (moderate temperatures, compatible fluids, and low pressures), a traditional rubber seal is often the more practical and economical option.

Ultimately, understanding the operational limits of your application is the key to selecting a seal that delivers both performance and value.

Summary Table:

| Property | PTFE Seals | Traditional Rubber Seals |

|---|---|---|

| Chemical Resistance | Excellent (Inert to most acids/bases) | Poor to Moderate (Swelling/Degradation) |

| Temperature Range | -200°C to +260°C+ | Limited (varies by type) |

| Coefficient of Friction | Very Low (~0.04) | Higher |

| Service Life | Very Long (Can exceed 40,000 hours) | Shorter |

| Pressure Handling | High (Can exceed 35 BAR / 500 PSI) | Lower |

| Elasticity/Conformability | Low (Requires precise finishes) | High (Forgiving of imperfections) |

| Relative Cost | Higher Initial Cost | Lower Initial Cost |

Need High-Performance PTFE Seals for Demanding Applications?

KINTEK specializes in manufacturing precision PTFE components, including seals, liners, and labware, for industries where failure is not an option. We serve the semiconductor, medical, laboratory, and industrial sectors, providing custom fabrication from prototypes to high-volume orders.

Partner with KINTEK to benefit from:

- Enhanced Reliability: Our PTFE seals ensure long-term performance in your most extreme operating conditions, reducing downtime.

- Expert Customization: We tailor solutions to meet your exact specifications, ensuring a perfect fit and optimal function.

- Precision Manufacturing: We prioritize quality and precision in every component we produce.

Let's discuss how our PTFE sealing solutions can improve your equipment's efficiency and reliability.

Contact our engineering team today for a consultation

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries use PTFE piston rings? Key Applications for Oil-Free & Corrosive Environments

- What are the main advantages of using Teflon gland packing? Achieve Superior Sealing and Lower Costs

- What medical applications benefit from extruded PTFE rods? Precision Components for Surgical & Diagnostic Devices

- What advantages does PTFE packing provide? Superior Chemical Resistance, Low Friction & Thermal Stability

- How is a spring energized PTFE seal defined? A High-Performance Solution for Extreme Conditions

- How do PTFE O-rings compare to Teflon O-rings? The Real Difference Between Solid and Encapsulated Designs

- What are the key features of PTFE diaphragms? Maximize Performance in Demanding Applications

- What economic advantages do ePTFE gaskets offer? Lower Total Cost of Ownership