In short, PTFE-based seals offer a powerful combination of advantages not found in most other sealing materials, most notably near-universal chemical resistance, an extremely wide operating temperature range, and the lowest coefficient of friction of any solid. These properties make them the superior choice for demanding and extreme industrial applications where conventional materials would quickly fail.

The core reason to choose a PTFE seal is for resilience in harsh conditions. While standard rubber seals are adequate for general-purpose use, PTFE is specifically engineered to solve problems related to aggressive chemicals, extreme temperatures, and high-speed dynamic applications.

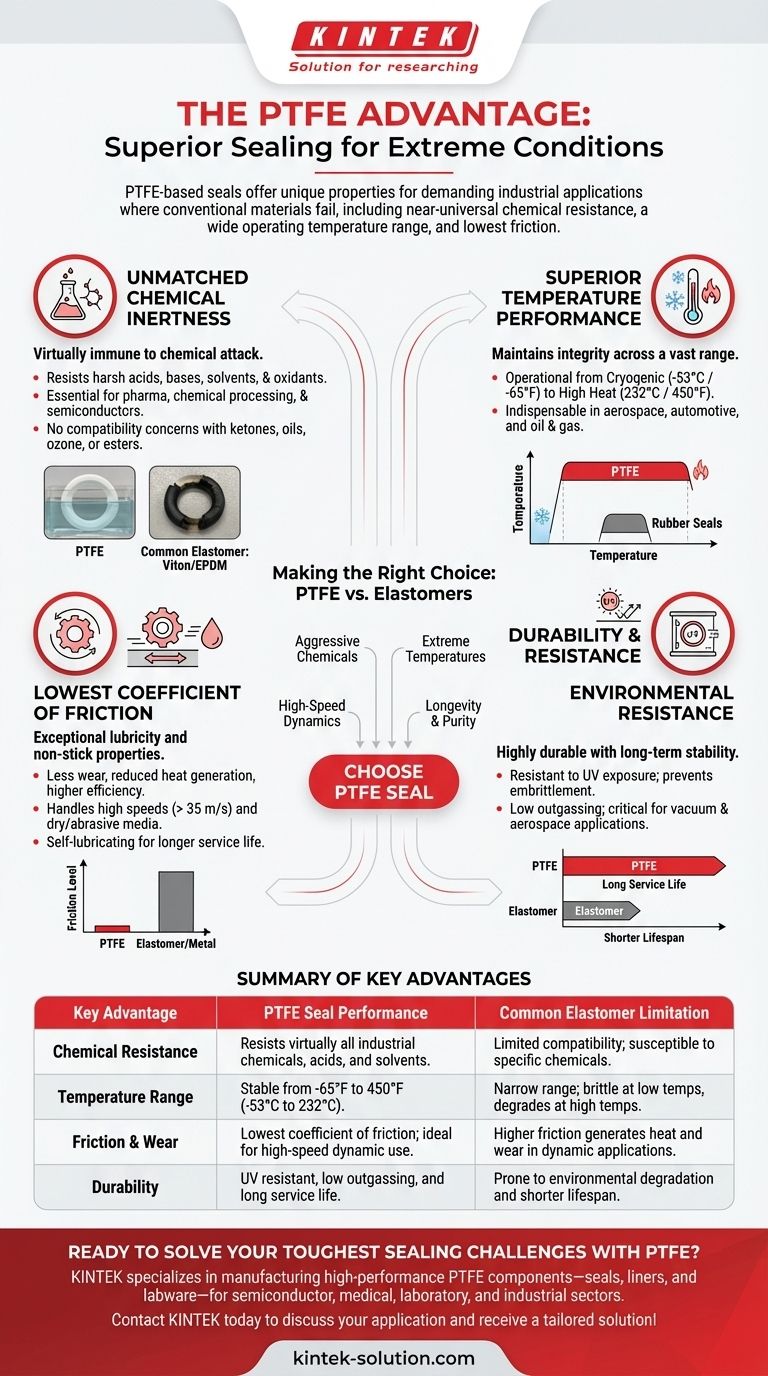

Unpacking the Core Strengths of PTFE Seals

To understand why PTFE is so valued, we must look beyond a simple list of features and analyze the practical impact of its unique material properties.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It resists erosion from almost all industrial chemicals, including strong acids, bases, solvents, and powerful oxidants.

This makes it an essential material in industries like pharmaceuticals, chemical processing, and semiconductor manufacturing, where fluid purity and seal integrity are non-negotiable.

In contrast, common elastomers have significant limitations. Viton is susceptible to ketones, EPDM performs poorly with oils and hydrocarbons, and Nitrile is incompatible with ozone and esters. PTFE eliminates these compatibility concerns.

Superior Performance Across Extreme Temperatures

PTFE seals maintain their integrity and dimensional stability across an exceptionally wide temperature range, from cryogenic conditions (-53°C / -65°F) to high heat (232°C / 450°F).

This thermal stability makes them indispensable in aerospace, automotive, and oil and gas applications, where components must perform reliably under severe temperature fluctuations.

The Lowest Coefficient of Friction

PTFE has the lowest coefficient of friction of any plastic, rubber, or metal, giving it exceptional lubricity and non-stick properties.

In practical terms, this means less wear, reduced heat generation, and higher efficiency in dynamic applications like rotating shafts or sliding parts. PTFE seals can handle high speeds (over 35 m/s) and can be used in dry or abrasive media where other seals would fail.

This self-lubricating characteristic also translates to a longer service life and reduced maintenance requirements.

Durability and Environmental Resistance

Beyond its thermal and chemical resistance, PTFE is highly durable. It is resistant to UV exposure, which prevents the embrittlement that can degrade other materials over time.

It also exhibits low outgassing, a critical property for vacuum applications and in the aerospace industry, where the release of trapped gases can compromise sensitive equipment.

Understanding the Engineering Trade-offs: PTFE vs. Elastomers

Choosing a seal material is not about finding a single "best" option, but about selecting the right material for a specific job. The decision to use PTFE often comes down to overcoming the inherent limitations of traditional elastomers.

Chemical Compatibility: The Deciding Factor

For applications involving aggressive media, PTFE is often the only viable choice. While an engineer might need to carefully check a compatibility chart for an EPDM or Viton seal, PTFE provides confidence that the seal will not dissolve, swell, or deteriorate when exposed to most fluids.

Temperature Range: Expanding the Operational Window

Standard rubber seals have a much narrower functional temperature range. They can become brittle and crack at low temperatures or soften and degrade at high temperatures. PTFE's ability to perform at both extremes significantly expands the design possibilities for equipment operating in harsh environments.

Friction and Wear: The Dynamic Advantage

In any application with movement, friction is an enemy. It creates heat, consumes energy, and causes wear. While elastomers can provide an excellent static seal, their higher friction makes them less suitable for high-speed dynamic use. PTFE’s low-friction nature makes it the definitive choice for reducing drag and extending the life of moving components.

Making the Right Choice for Your Application

Selecting the correct seal material is fundamental to ensuring equipment reliability and safety. Your decision should be guided by the most demanding aspect of your operating environment.

- If your primary focus is handling aggressive chemicals: Choose PTFE for its near-universal inertness, which guarantees seal integrity where most elastomers would fail.

- If your primary focus is extreme temperatures: PTFE's wide operational range provides stability from cryogenic lows to high-heat environments.

- If your primary focus is high-speed or dynamic sealing: PTFE's extremely low coefficient of friction is essential for minimizing wear, heat, and energy loss.

- If your primary focus is longevity and purity: Select PTFE for its resistance to environmental degradation and its low outgassing properties, ensuring a long and reliable service life.

Ultimately, specifying a PTFE seal is an investment in performance and reliability for your most critical applications.

Summary Table:

| Key Advantage | PTFE Seal Performance | Common Elastomer Limitation |

|---|---|---|

| Chemical Resistance | Resists virtually all industrial chemicals, acids, and solvents. | Limited compatibility; susceptible to specific chemicals. |

| Temperature Range | Stable from -65°F to 450°F (-53°C to 232°C). | Narrow range; brittle at low temps, degrades at high temps. |

| Friction & Wear | Lowest coefficient of friction; ideal for high-speed dynamic use. | Higher friction generates heat and wear in dynamic applications. |

| Durability | UV resistant, low outgassing, and long service life. | Prone to environmental degradation and shorter lifespan. |

Ready to solve your toughest sealing challenges with PTFE?

KINTEK specializes in manufacturing high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get a seal engineered for resilience, longevity, and peak performance in your specific environment.

Contact KINTEK today to discuss your application and receive a tailored solution!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the advantages of PTFE sliding bearings in terms of size and design flexibility? Achieve Compact, Custom Solutions

- What are the benefits of smart monitoring integration in Teflon gland packing? Achieve Predictive Maintenance & Zero Downtime

- What are some tips for successful Teflon machining? Master Precision Cuts for PTFE Components

- Which industries commonly use PTFE seals and why? Unlock Unmatched Performance in Harsh Environments

- What are the application advantages of PTFE backup rings? Boost System Reliability in Extreme Conditions

- What should be considered when selecting a CNC machining service for PTFE? Key Factors for Precision Parts

- What are the key characteristics of PTFE oil seals? Unlock Superior Performance in Extreme Conditions

- Why are PTFE bellows preferred in the food, dairy, and pharmaceutical industries? Ensure Uncompromising Product Purity and Safety