To put it simply, PTFE seals are defined by three core characteristics: an extremely wide operating temperature range, near-universal chemical resistance, and an inherently low-friction surface that requires no external lubrication. These properties make them a superior choice for demanding industrial, automotive, and aerospace applications where conventional seals would quickly fail.

The decision to use a PTFE seal is fundamentally a decision to solve an extreme engineering challenge. While other materials handle standard conditions, PTFE is specified when performance under high heat, aggressive chemicals, or high-speed dynamics is non-negotiable.

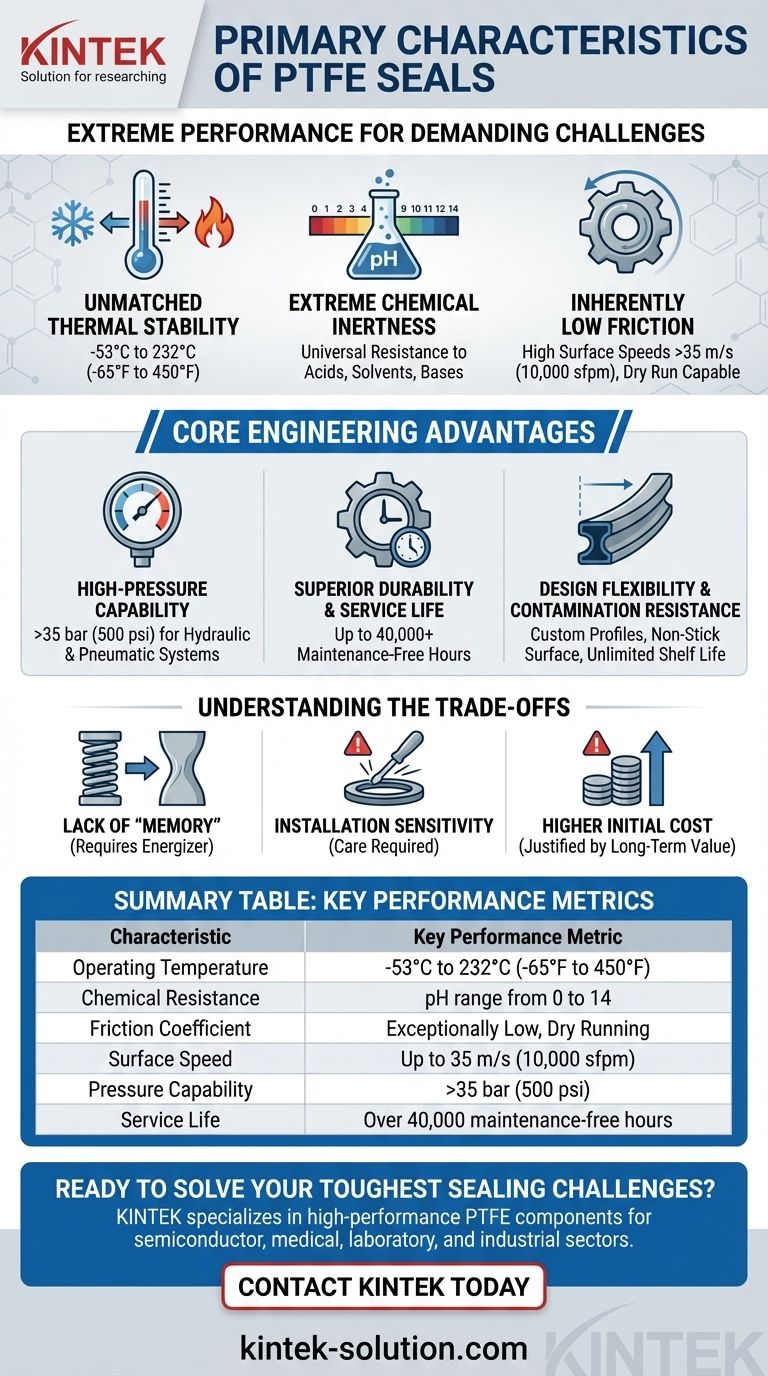

The Core Engineering Advantages of PTFE

Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer, often called the "King of Plastics." Its molecular structure gives it a unique combination of properties that translate directly into superior sealing performance in harsh environments.

Unmatched Thermal Stability

PTFE seals operate reliably across an exceptionally broad temperature range, typically from -53°C to 232°C (-65°F to 450°F), with some formulations extending this even further.

This stability allows them to function equally well in cryogenic applications as they do in high-temperature automotive engines or industrial machinery, where traditional rubber seals would become brittle or degrade.

Extreme Chemical Inertness

PTFE is one of the most chemically inert materials known, capable of handling fluids with a pH range from 0 to 14.

This makes it indispensable for sealing against aggressive acids, solvents, bases, and oils. It is the material of choice in industries like chemical processing, pharmaceuticals, and semiconductor manufacturing where seal integrity is critical.

Inherently Low Friction

PTFE has an exceptionally low coefficient of friction, one of the lowest of any solid material. This property is inherent to the material and does not rely on lubrication.

This high lubricity reduces wear, minimizes heat generation, and allows for very high surface speeds—sometimes over 35 m/s (10,000 sfpm). It also enables the seal to run dry or in abrasive media without failing.

High-Pressure Capability

Engineered PTFE seals are designed to maintain their integrity under significant force, often handling pressures in excess of 35 bar (500 psi).

This makes them highly suitable for demanding hydraulic and pneumatic systems where pressure containment is a primary function.

Practical Benefits in Demanding Applications

The core scientific properties of PTFE translate into tangible operational advantages, primarily focused on reliability and reduced long-term cost.

Superior Durability and Service Life

The combination of wear resistance, chemical stability, and thermal endurance gives PTFE seals a remarkably long service life. In some applications, they can achieve over 40,000 maintenance-free hours.

This durability dramatically reduces equipment downtime and the associated maintenance costs, providing a lower total cost of ownership.

Design Flexibility and Adaptability

PTFE's properties allow it to be custom-designed into a wide variety of seal profiles. It is also flexible enough to conform to various shaft dimensions and surface imperfections, ensuring a tight seal.

Furthermore, PTFE possesses an unlimited shelf life, as it does not degrade from exposure to UV, moisture, or other environmental factors.

Contamination Resistance

The material's non-stick properties prevent contaminants, sludge, or other media from building up on the seal's surface. This ensures consistent performance and prevents premature failure caused by adhesion.

Understanding the Trade-offs

While PTFE offers exceptional performance, it is not a universal solution. Understanding its limitations is key to using it effectively.

Lack of "Memory" Compared to Elastomers

Unlike rubber or other elastomers, PTFE is not truly elastic. It does not rebound to its original shape after being compressed.

For this reason, many PTFE seals incorporate a spring or O-ring energizer to provide the constant force needed to maintain a tight seal, especially in low-pressure or static applications.

Installation Sensitivity

Because it is a harder, less forgiving material than rubber, PTFE seals require more care during installation. Scoring or scratching the sealing lip can compromise its performance, so proper tools and procedures are essential.

Higher Initial Cost

As a high-performance material, PTFE typically has a higher upfront cost compared to standard elastomeric seals like Nitrile or Viton. This cost is justified by its dramatically longer service life and ability to perform in conditions where other materials cannot.

Making the Right Choice for Your Goal

The decision to use a PTFE seal should be driven by the specific demands of your application.

- If your primary focus is extreme temperatures: PTFE's wide operating range makes it a default choice for applications involving cryogenic fluids or high-heat engines.

- If your primary focus is aggressive chemicals: The chemical inertness of PTFE is essential for sealing in pharmaceutical, food processing, or chemical manufacturing environments.

- If your primary focus is high-speed rotation or dry running: PTFE's uniquely low friction minimizes heat generation and wear, far outperforming traditional elastomeric seals.

- If your primary focus is high pressure: Properly designed PTFE seals excel in hydraulic and pneumatic systems where standard seals would extrude or fail.

Ultimately, selecting a PTFE seal is a decision to prioritize reliability and performance in conditions where other materials cannot survive.

Summary Table:

| Characteristic | Key Performance Metric |

|---|---|

| Operating Temperature | -53°C to 232°C (-65°F to 450°F) |

| Chemical Resistance | pH range from 0 to 14 |

| Friction Coefficient | Exceptionally low, allows dry running |

| Surface Speed | Up to 35 m/s (10,000 sfpm) |

| Pressure Capability | > 35 bar (500 psi) |

| Service Life | Over 40,000 maintenance-free hours in some applications |

Ready to Solve Your Toughest Sealing Challenges?

Your application demands reliability under extreme heat, aggressive chemicals, or high-speed dynamics. KINTEK specializes in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We deliver precision-engineered solutions, from prototypes to high-volume orders, ensuring your equipment operates flawlessly in the most demanding conditions.

Contact KINTEK today to discuss your specific requirements and discover how our PTFE expertise can enhance your product's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal