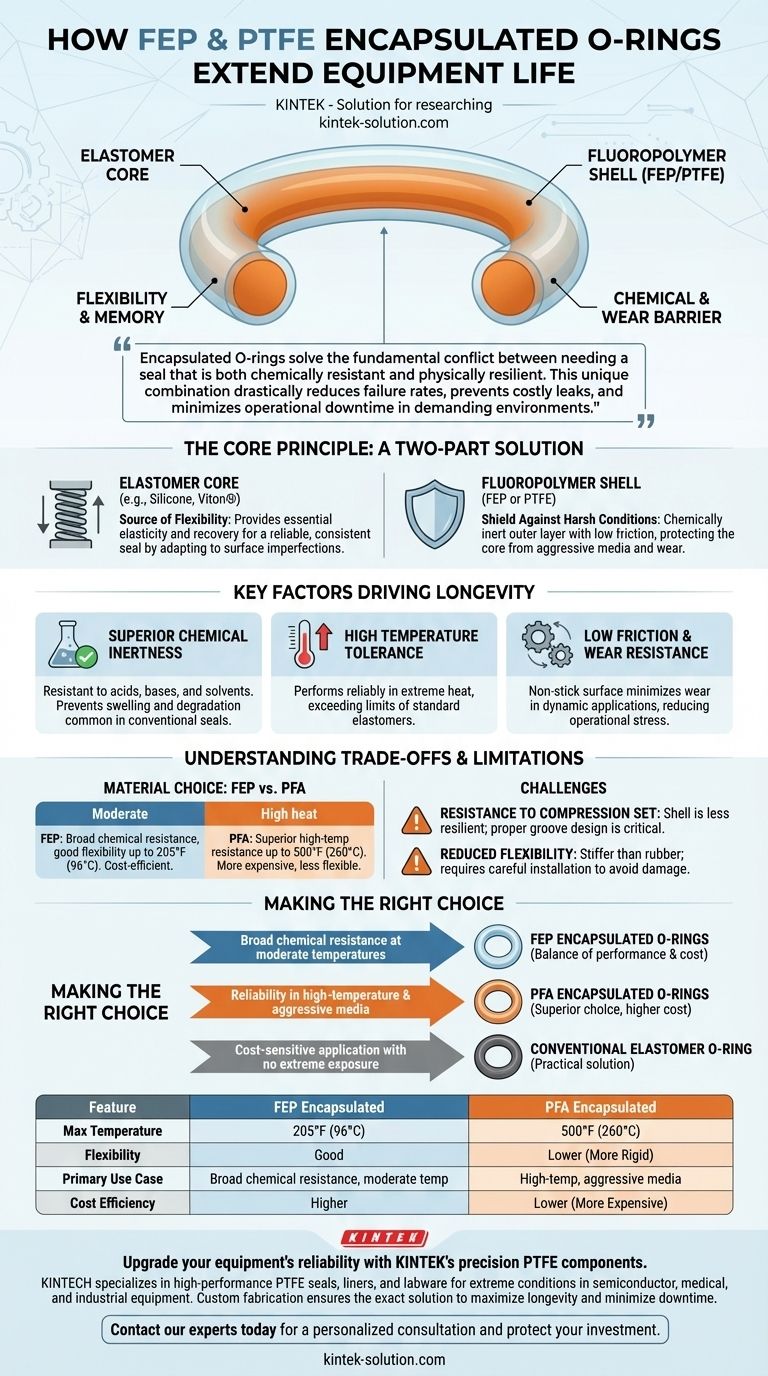

At their core, FEP and PTFE encapsulated O-rings extend equipment life by creating a nearly indestructible barrier. They achieve this by combining the flexibility and memory of an elastomer core with a seamless outer shell of fluoropolymer. This dual-material design directly prevents the most common causes of seal failure: chemical degradation from corrosive fluids and mechanical wear from friction.

Encapsulated O-rings solve the fundamental conflict between needing a seal that is both chemically resistant and physically resilient. This unique combination drastically reduces failure rates, prevents costly leaks, and minimizes operational downtime in demanding environments.

The Core Principle: A Two-Part Solution for Sealing

To understand their effectiveness, you must see these O-rings not as a single material, but as a composite system where each part serves a distinct purpose.

The Elastomer Core: The Source of Flexibility

The inner core, typically made of silicone or Viton®, provides the elasticity and recovery properties essential for a reliable seal.

This core allows the O-ring to compress into a groove and exert consistent pressure, adapting to surface imperfections and maintaining a leak-free connection.

The Fluoropolymer Shell: The Shield Against Harsh Conditions

The outer layer of FEP (Fluorinated Ethylene Propylene) or PTFE (Polytetrafluoroethylene) is what contacts the aggressive media.

This seamless shell is virtually chemically inert and has an extremely low coefficient of friction. It acts as an impenetrable shield, protecting the vulnerable elastomer core from degradation.

Key Factors Driving Equipment Longevity

The unique construction of encapsulated O-rings translates directly into a longer operational life for both the seal and the equipment it protects.

Superior Chemical Inertness

These seals are resistant to a vast range of aggressive chemicals, including acids, bases, and solvents.

Where a conventional rubber seal would swell, harden, or dissolve, an encapsulated O-ring maintains its integrity, ensuring reliable sealing in pumps, valves, and reactors.

High Temperature Tolerance

Standard elastomers can fail quickly when exposed to extreme temperatures.

The fluoropolymer encapsulation allows these O-rings to perform reliably at temperatures far beyond the limits of most conventional seals, preventing leaks and unscheduled maintenance.

Low Friction and Wear Resistance

The non-stick, low-friction surface of the PTFE or FEP shell minimizes wear and tear on moving parts.

In dynamic applications like pump shafts or valve stems, this reduces operational stress on the entire assembly, contributing to the longevity of the equipment itself.

Understanding the Trade-offs and Limitations

While highly effective, encapsulated O-rings are a specialized solution. Understanding their limitations is critical for proper application.

Material Choice: FEP vs. PFA

FEP encapsulation is an excellent choice for broad chemical resistance and offers good flexibility for temperatures up to 205°F (96°C).

For more demanding, high-temperature environments, PFA (Perfluoroalkoxy) is a better option, with resistance up to 500°F (260°C). However, PFA is more expensive and noticeably less flexible, which can make installation more difficult.

Resistance to Compression Set

While the core provides elasticity, the fluoropolymer shell is less resilient than rubber. If over-compressed or held at high temperatures for long periods, it can take a permanent "set."

This means proper groove design and avoiding excessive squeeze are more critical than with standard O-rings to ensure long-term performance.

Reduced Flexibility

The encapsulation makes these seals inherently stiffer than a standard all-rubber O-ring. This demands more careful and precise installation to avoid scratching or damaging the thin outer shell, which would compromise its protective capabilities.

Making the Right Choice for Your Application

To select the correct seal, you must align the material properties directly with your primary operational challenge.

- If your primary focus is broad chemical resistance at moderate temperatures: FEP encapsulated O-rings offer the best balance of performance, flexibility, and cost-efficiency.

- If your primary focus is reliability in high-temperature and aggressive media: PFA encapsulated O-rings are the superior choice, despite their higher cost and lower flexibility.

- If your primary focus is a cost-sensitive application with no extreme chemical or temperature exposure: A conventional, non-encapsulated elastomer O-ring is often the more practical and sufficient solution.

Choosing the right seal is a direct investment in the long-term reliability and profitability of your equipment.

Summary Table:

| Feature | FEP Encapsulated O-rings | PFA Encapsulated O-rings |

|---|---|---|

| Max Temperature | 205°F (96°C) | 500°F (260°C) |

| Flexibility | Good | Lower (More Rigid) |

| Primary Use Case | Broad chemical resistance at moderate temperatures | High-temperature, aggressive media |

| Cost Efficiency | Higher | Lower (More Expensive) |

Upgrade your equipment's reliability with KINTEK's precision PTFE components.

Facing challenges with chemical degradation, high temperatures, or frequent seal failure in your semiconductor, medical, or industrial equipment? KINTECH specializes in manufacturing high-performance PTFE seals, liners, and labware designed for extreme conditions. Our custom fabrication services—from prototypes to high-volume orders—ensure you get the exact encapsulated O-ring solution to maximize your equipment's longevity and minimize costly downtime.

Contact our experts today for a personalized consultation and see how our precision components can protect your investment.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for drilling and tapping PTFE? Achieve Clean, Precise Machining

- How does Teflon's performance in extreme temperatures benefit industrial applications? Ensuring Reliable Performance from -200°C to +260°C

- Why are PTFE gaskets considered reliable sealing solutions? Unmatched Chemical & Thermal Stability

- What industries are PTFE gaskets particularly suitable for? Ideal for Chemical, Pharma, and Food Processing

- What types of projects are Teflon sheets compatible with? From Crafts to Industry

- What are the key properties of Teflon sheets? A Guide to PTFE's Versatility

- How does the PTFE lining extend the valve's service life? The Ultimate Shield Against Corrosion and Wear

- What are the benefits of porous PTFE? Unlock Superior Filtration and Chemical Resistance