At its core, Expanded Polytetrafluoroethylene (ePTFE) is the material of choice for sealing applications in the world's most demanding and sensitive industries. It is most commonly used in the chemical, pharmaceutical, food processing, petrochemical, and semiconductor manufacturing sectors due to its unique combination of chemical inertness and robust sealing capabilities.

The widespread adoption of ePTFE gaskets stems from a single, critical need: creating a reliable, long-lasting seal in environments where chemical attack, temperature extremes, and product purity are non-negotiable concerns.

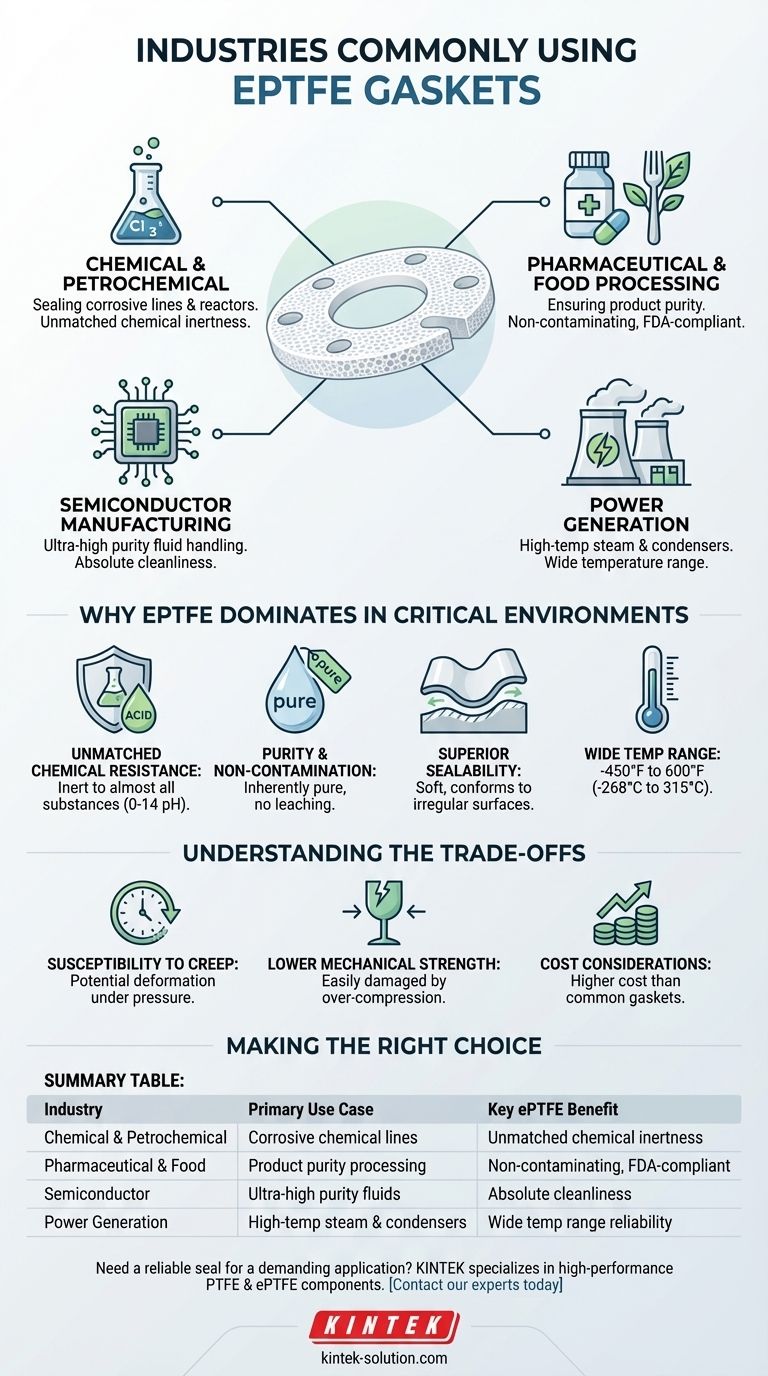

Why ePTFE Dominates in Critical Environments

The value of ePTFE goes beyond simply being a durable plastic. Its unique manufacturing process creates a microporous structure that gives it properties far superior to standard, solid PTFE for many sealing applications.

Unmatched Chemical Resistance

ePTFE is chemically inert to almost all substances across the entire 0-14 pH range. The only exceptions are molten alkali metals and elemental fluorine.

This makes it the default choice for sealing pipes, valves, and vessels containing aggressive acids, caustics, and solvents that would rapidly degrade other materials.

Purity and Non-Contamination

Standard ePTFE gaskets are inherently pure and do not leach contaminants into the process media. This is an absolute requirement in industries where even trace amounts of impurities can ruin a product batch.

This property is critical for applications in pharmaceutical manufacturing, food and beverage processing, and the production of ultra-pure chemicals for the semiconductor industry.

Superior Sealability on Irregular Surfaces

The "expanded" nature of ePTFE makes it soft and highly conformable. It can effectively fill in scratches, pits, and waviness on flange faces.

This is invaluable for creating a tight seal on older, damaged, or warped equipment, where a more rigid gasket material would inevitably fail. It allows for reliable sealing with lower bolt loads, reducing stress on sensitive equipment like plastic or glass-lined flanges.

Wide Service Temperature Range

ePTFE gaskets perform reliably across an exceptionally broad temperature spectrum, typically from -450°F to 600°F (-268°C to 315°C).

This versatility allows them to be used in applications ranging from cryogenic services to high-temperature chemical reactors and exhaust systems without losing their sealing integrity.

Core Industrial Applications Breakdown

The properties of ePTFE directly translate to its use in specific, high-stakes industrial settings.

Chemical and Petrochemical Processing

In this sector, ePTFE gaskets are used to seal flanges, pump housings, and heat exchangers that handle highly corrosive chemicals, often at extreme temperatures and pressures.

Pharmaceutical and Food & Beverage

Here, the primary drivers are purity and compliance. ePTFE's non-contaminating nature ensures product integrity and helps meet stringent FDA and other regulatory standards.

Semiconductor and Electronics Manufacturing

The need for ultra-high purity is paramount. ePTFE gaskets are used in fluid handling systems for manufacturing microchips, where any contamination would lead to defects and costly yield loss.

Power Generation and Energy

From nuclear power plants to traditional fossil fuel facilities, ePTFE seals steam lines, condensers, and other critical equipment that operate under high thermal stress.

Understanding the Trade-offs

While highly effective, ePTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Susceptibility to Creep

Like all PTFE materials, ePTFE is subject to "creep" or "cold flow." Over time, under the pressure of a bolted flange, the material can slowly deform, which may lead to a loss of bolt load and potential leakage.

Proper installation techniques, including using torque wrenches and following specified patterns, are essential to mitigate this. In some high-temperature or high-pressure applications, periodic re-torquing may be necessary.

Lower Mechanical Strength

ePTFE is a soft material. While this aids in sealability, it also means it can be easily damaged by over-compression. It lacks the rigidity and blowout resistance of metallic or semi-metallic gaskets.

Cost Considerations

High-performance materials come at a higher cost. ePTFE is typically more expensive than common non-asbestos or elastomeric (rubber) gaskets, making it a targeted solution for critical applications rather than general-purpose use.

Making the Right Choice for Your Goal

Selecting the correct gasket material is a crucial engineering decision that balances performance, safety, and cost.

- If your primary focus is containing aggressive chemicals: ePTFE's near-universal chemical inertness makes it one of the safest and most reliable choices.

- If your primary focus is absolute product purity: The non-contaminating nature of ePTFE is essential for food, pharmaceutical, and high-purity applications.

- If you are sealing old or damaged flange surfaces: The superior conformability of ePTFE can provide a reliable seal where more rigid gaskets are likely to fail.

- If your application involves low pressure, mild chemicals, and perfect flanges: A more economical material, such as a compressed non-asbestos fiber sheet, may be a more cost-effective solution.

Ultimately, choosing ePTFE is an investment in reliability for applications where seal failure is not an option.

Summary Table:

| Industry | Primary Use Case | Key ePTFE Benefit |

|---|---|---|

| Chemical & Petrochemical | Sealing corrosive chemical lines & reactors | Unmatched chemical inertness |

| Pharmaceutical & Food | Ensuring product purity in processing | Non-contaminating, FDA-compliant |

| Semiconductor | Ultra-high purity fluid handling | Absolute cleanliness for chip yield |

| Power Generation | High-temperature steam & condensers | Wide temperature range reliability |

Need a reliable seal for a demanding application? KINTEK specializes in manufacturing high-performance PTFE and ePTFE components, including custom gaskets, seals, and liners. Our precision production ensures the chemical resistance and purity required by the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we deliver solutions you can trust. Contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance