In custom fabrication, the key benefits of PTFE stem from its unique molecular structure. This structure grants it an unparalleled combination of chemical inertness, an extremely low coefficient of friction, and high-temperature resistance, making it a premier material for components destined for harsh and demanding operational environments.

PTFE is not just another high-performance plastic; it is an engineering solution for extreme conditions. Its value lies in its ability to reliably perform in corrosive, high-temperature, and high-friction applications where nearly all other materials would fail.

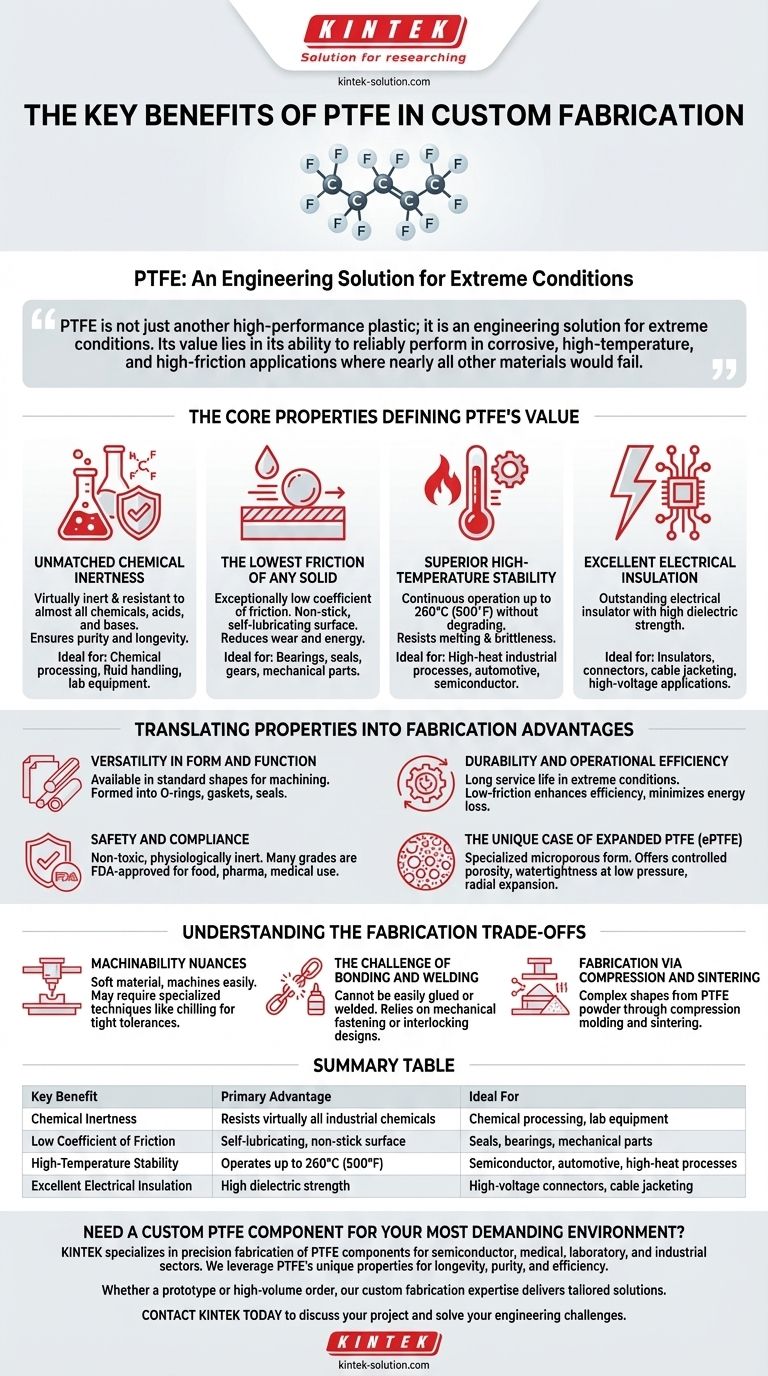

The Core Properties Defining PTFE's Value

Polytetrafluoroethylene (PTFE) is a fluoropolymer with properties derived directly from its strong carbon-fluorine bonds. These bonds are responsible for its most significant advantages in custom fabrication.

Unmatched Chemical Inertness

PTFE is virtually inert and resistant to almost all industrial chemicals, acids, and bases. This makes it an ideal choice for components used in chemical processing, fluid handling, and laboratory equipment.

The material's non-corrosive nature ensures the purity of the substances it contacts and guarantees the longevity of the fabricated part itself.

The Lowest Friction of Any Solid

PTFE possesses an exceptionally low coefficient of friction, resulting in a non-stick, self-lubricating surface.

This property is critical for mechanical applications like bearings, seals, and gears. It drastically reduces wear and tear on moving parts and lowers the energy required for operation.

Superior High-Temperature Stability

Custom PTFE components can operate continuously at temperatures up to 260°C (500°F) without degrading.

This wide operating temperature range allows it to be used in high-heat industrial processes, from automotive systems to semiconductor manufacturing, where other plastics would melt or become brittle.

Excellent Electrical Insulation

PTFE is an outstanding electrical insulator with a high dielectric strength. This makes it an essential material for fabricating insulators, connectors, and cable jacketing for high-voltage and high-frequency applications.

Translating Properties into Fabrication Advantages

The inherent properties of PTFE directly translate into tangible benefits for custom-fabricated parts across various industries.

Versatility in Form and Function

PTFE is available in standard shapes like sheets, rods, tubes, and films, which serve as the base for machining custom parts.

It can also be formed into highly specific components such as O-rings, gaskets, and seals, offering reliable performance in demanding sealing applications under low to medium pressure.

Durability and Operational Efficiency

The combination of chemical resistance, weatherability, and low friction gives PTFE components a long service life, even in extreme conditions. This durability reduces maintenance cycles and replacement costs.

Its low-friction surface enhances operational efficiency by minimizing energy loss in mechanical systems.

Safety and Compliance

PTFE is non-toxic and physiologically inert. Many grades are FDA-approved, making it safe for use in food processing, pharmaceutical, and medical applications.

The Unique Case of Expanded PTFE (ePTFE)

A specialized form, expanded PTFE (ePTFE), introduces a microporous structure. This provides all the core benefits of PTFE plus new capabilities like controlled porosity, watertightness at low pressure, and excellent radial expansion.

Understanding the Fabrication Trade-offs

While PTFE's properties are exceptional, they also introduce specific considerations and limitations that are critical to understand during the design and fabrication process.

Machinability Nuances

PTFE is a soft material that machines easily, allowing for the creation of precise and complex parts. However, its softness means that specialized techniques, such as chilling the material, may be required to achieve tight tolerances.

The Challenge of Bonding and Welding

One of the most significant limitations of PTFE is that it cannot be easily glued or welded. Its non-stick, low-energy surface repels virtually all adhesives.

This characteristic means that custom assemblies must rely on mechanical fastening or interlocking designs rather than chemical bonding.

Fabrication via Compression and Sintering

For complex shapes that are difficult to machine, PTFE powder can be shaped through compression molding and then heated in a process called sintering. This fuses the particles into a solid, durable part.

Choosing PTFE for Your Application

Your final decision should be guided by the primary challenge your component needs to overcome.

- If your primary focus is corrosive environments: PTFE is the definitive choice for parts that handle aggressive chemicals, ensuring both component longevity and process purity.

- If your primary focus is mechanical efficiency: Use PTFE for low-friction bearings, non-stick surfaces, or seals to significantly reduce wear, system drag, and energy consumption.

- If your primary focus is high-temperature or electrical needs: PTFE excels as a stable thermal and electrical insulator in applications where other materials would fail due to heat or high voltage.

- If your primary focus is complex assemblies: Design with mechanical fasteners in mind, as the inability to glue or weld PTFE is a fundamental constraint of the material.

Ultimately, selecting PTFE for custom fabrication is a decision to prioritize performance and reliability in the most challenging engineering environments.

Summary Table:

| Key Benefit | Primary Advantage | Ideal For |

|---|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals | Chemical processing, lab equipment |

| Low Coefficient of Friction | Self-lubricating, non-stick surface | Seals, bearings, mechanical parts |

| High-Temperature Stability | Operates up to 260°C (500°F) | Semiconductor, automotive, high-heat processes |

| Excellent Electrical Insulation | High dielectric strength | High-voltage connectors, cable jacketing |

Need a custom PTFE component that can withstand your most demanding environment?

KINTEK specializes in the precision fabrication of PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. We leverage PTFE's unique properties to deliver parts that ensure longevity, purity, and efficiency in extreme conditions.

Whether you require a prototype or a high-volume order, our expertise in custom fabrication means we can deliver a solution tailored to your specific needs.

Contact KINTEK today to discuss your project and discover how our PTFE components can solve your engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments