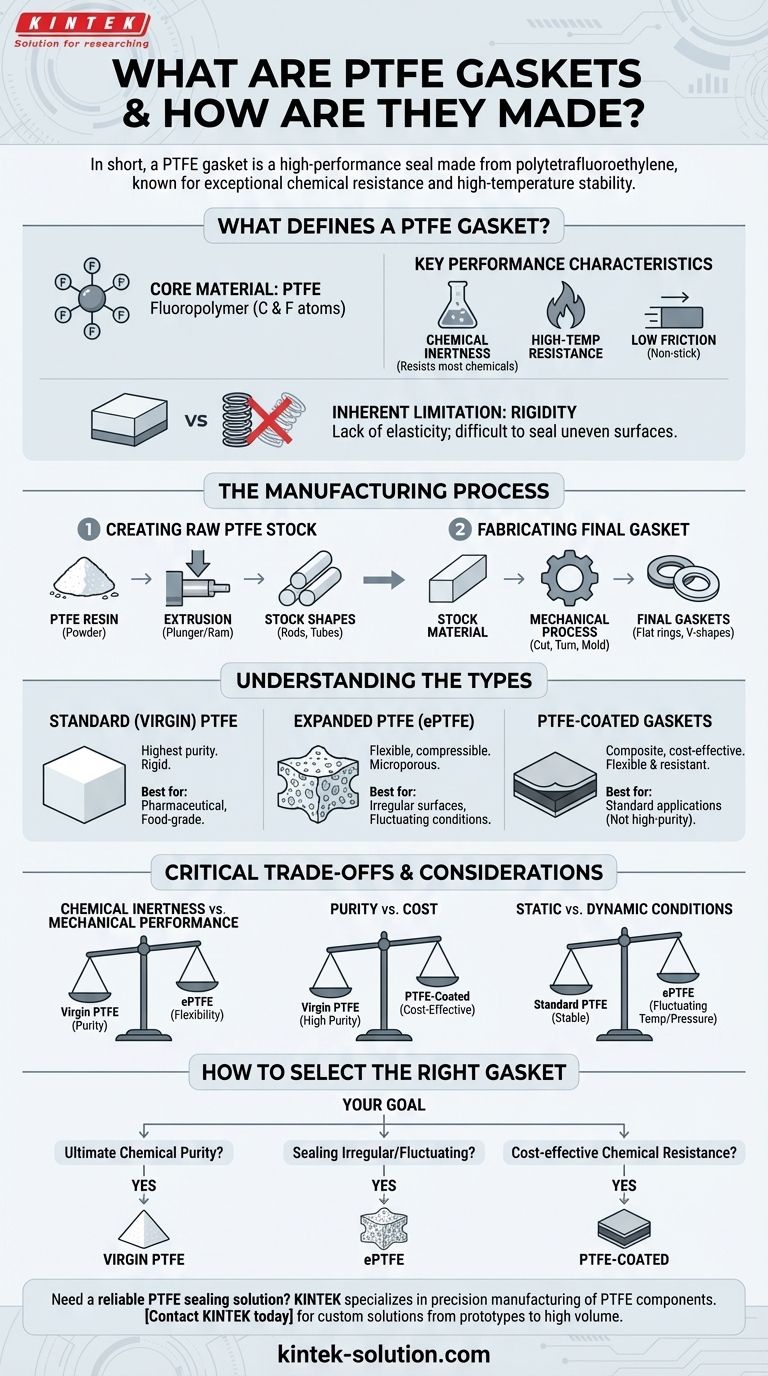

In short, a PTFE gasket is a high-performance seal made from polytetrafluoroethylene, a synthetic fluoropolymer known for its exceptional chemical resistance and ability to withstand high temperatures. These gaskets are typically made by first forming raw PTFE resin into stock shapes like rods or tubes through an extrusion process, and then mechanically cutting, turning, or molding that stock into its final, precise form.

The central challenge with PTFE gaskets is balancing their unmatched chemical inertness against their inherent mechanical rigidity. Understanding the different forms—standard, expanded (ePTFE), and coated—is crucial for choosing a seal that meets both the chemical and physical demands of your application.

What Defines a PTFE Gasket?

To properly select a gasket, you must first understand the fundamental properties of the material itself. Polytetrafluoroethylene (PTFE) offers a unique combination of strengths and weaknesses.

The Core Material: Polytetrafluoroethylene

PTFE is a fluoropolymer composed of carbon and fluorine atoms. It was the first fluoropolymer ever manufactured and is valued for a unique set of characteristics that make it ideal for demanding sealing applications.

Key Performance Characteristics

The primary advantages of PTFE are its extreme chemical inertness and high-temperature resistance. It does not react with most industrial chemicals, making it a reliable choice for sealing corrosive media.

It also has an exceptionally low coefficient of friction, giving it non-stick properties that prevent material buildup on the gasket surface.

The Inherent Limitation: Rigidity

The most significant drawback of standard PTFE is its lack of elasticity. Unlike rubber, it is a rigid material that does not easily return to its original shape after being compressed. This can make it difficult to create a tight seal, especially on uneven or imperfect surfaces.

The Manufacturing Process from Resin to Seal

Creating a PTFE gasket is a two-stage process that involves producing the raw material stock and then fabricating the final part.

Step 1: Creating the Raw PTFE Stock

The process begins with PTFE resin. This raw material is processed into usable forms like rods or tubes using methods such as plunger extrusion or ram extrusion. The specific method depends on the desired shape and wall thickness of the stock material.

Step 2: Fabricating the Final Gasket

Once the stock material is produced, the final gasket is fabricated. This is a mechanical process where the rods, sheets, or tubes are precisely cut, turned, or molded into specific shapes like flat rings, V-shaped gaskets, or piston rings.

Understanding the Types of PTFE Gaskets

The limitations of standard PTFE have led to the development of several variations. Each type is engineered to solve a different set of problems.

Standard (Virgin) PTFE

This is pure, solid PTFE. It offers the highest level of chemical purity and is the go-to choice for applications in pharmaceutical or food processing where preventing contamination is critical. Its primary weakness remains its rigidity.

Expanded PTFE (ePTFE)

To overcome rigidity, ePTFE is created by mechanically stretching standard PTFE. This process creates a microporous structure that makes the material soft, flexible, and highly compressible. ePTFE is excellent for sealing irregular surfaces or applications with fluctuating temperatures and pressures.

PTFE-Coated Gaskets

These are composite gaskets, typically with a rubber or metal core that is coated with a thin layer of PTFE. This design combines the mechanical flexibility and resilience of the core material with the chemical resistance of the PTFE surface. However, they are not suitable for high-purity applications.

Critical Trade-offs and Considerations

Choosing the right gasket requires an objective look at the trade-offs between different material properties and application demands.

Chemical Inertness vs. Mechanical Performance

The core dilemma is often between the absolute purity of virgin PTFE and the superior sealing capability of ePTFE. If your flange surfaces are perfect and bolt load is high, virgin PTFE may suffice. If not, the flexibility of ePTFE is a safer choice.

Purity vs. Cost

PTFE-coated gaskets offer a cost-effective way to gain chemical resistance. However, the presence of a rubber or metal core makes them unsuitable for applications like pharmaceutical manufacturing where product purity is non-negotiable and must meet stringent regulatory standards.

Static vs. Dynamic Conditions

Standard PTFE performs well in stable, static sealing applications. For systems with significant temperature or pressure fluctuations, the enhanced flexibility and compressibility of ePTFE provide a much more reliable and durable seal.

How to Select the Right PTFE Gasket

Your specific goal will determine the best type of PTFE gasket for the job.

- If your primary focus is ultimate chemical purity and inertness: Virgin PTFE is the definitive choice for sensitive applications like pharmaceutical or food-grade systems.

- If your primary focus is sealing irregular surfaces or withstanding fluctuating conditions: Expanded PTFE (ePTFE) provides the necessary flexibility and compressibility for a reliable seal.

- If your primary focus is adding chemical resistance to a standard application: A PTFE-coated gasket can be a cost-effective solution, provided high purity is not a requirement.

By understanding these fundamental distinctions, you can leverage the unique strengths of PTFE to ensure a reliable and long-lasting seal in even the most demanding environments.

Summary Table:

| Gasket Type | Key Characteristics | Best For |

|---|---|---|

| Standard (Virgin) PTFE | Highest chemical purity, rigid | Pharmaceutical, food-grade, high-purity applications |

| Expanded PTFE (ePTFE) | Flexible, compressible, microporous | Irregular surfaces, fluctuating temperatures/pressures |

| PTFE-Coated | Cost-effective, combines flexibility with chemical resistance | Standard applications where high purity is not critical |

Need a reliable PTFE sealing solution for your demanding application?

KINTEK specializes in the precision manufacturing of PTFE components, including seals, gaskets, liners, and custom labware. Whether you require the absolute purity of virgin PTFE for a pharmaceutical process or the superior flexibility of ePTFE for challenging flange conditions, our expertise ensures a perfect match for your needs in the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get a seal that delivers unmatched performance and longevity.

Contact KINTEK today to discuss your specific requirements and let our experts provide a solution that guarantees a leak-free, reliable seal.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech