At their core, PTFE rotary shaft seals are suitable for food and beverage processing because they uniquely combine regulatory compliance with extreme operational resilience. Made from a synthetic fluoropolymer, these seals are chemically inert, meet stringent FDA standards for food contact, and can withstand the aggressive cleaning agents, high pressures, and high rotational speeds common in the industry.

The choice of PTFE is not just about meeting a single requirement. It is about satisfying two critical, often conflicting, needs simultaneously: ensuring absolute product purity and safety while delivering exceptional mechanical performance and longevity in a harsh processing environment.

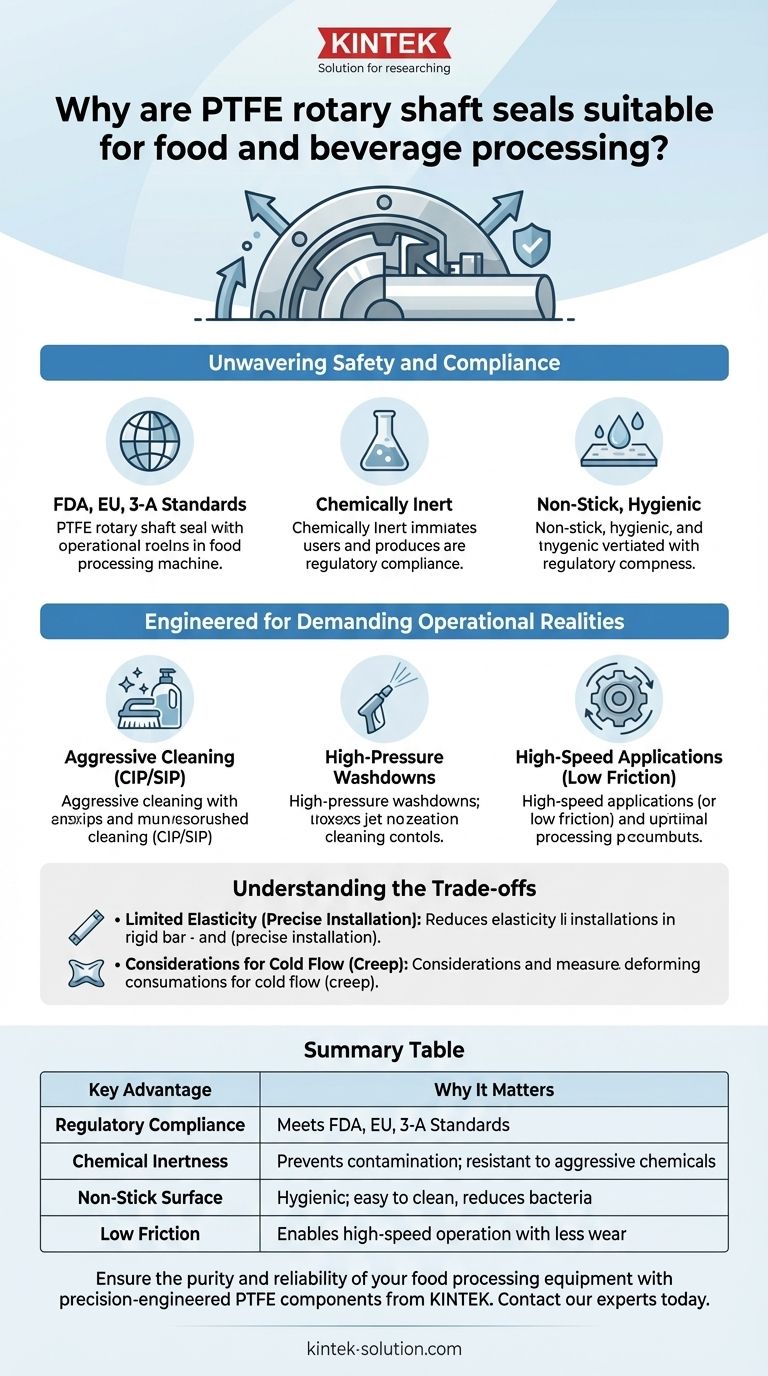

The Foundation: Unwavering Safety and Compliance

In food and beverage production, the primary directive is to prevent contamination. The materials used in processing equipment are the first line of defense.

Meeting Stringent Regulatory Standards

PTFE is one of the few high-performance polymers that satisfies the most critical global standards for food safety.

This includes FDA 21 CFR 177.1550 for direct food contact, (EU) 1935/2004 for food-contact materials, and 3-A Sanitary Standards, which are specifically designed to ensure the hygienic design and cleanability of equipment.

Ensuring Product Purity with Chemical Inertness

PTFE is exceptionally non-reactive. It does not leach chemicals, flavors, or odors into the food products it contacts.

This chemical inertness guarantees that the purity, taste, and safety of the end product remain uncompromised, regardless of the food type being processed.

The Advantage of a Non-Stick, Hygienic Surface

The famous non-stick property of PTFE is a significant hygienic benefit. This characteristic prevents food particles and microorganisms from adhering to the seal's surface.

As a result, equipment is easier to clean thoroughly, reducing the risk of bacterial growth and cross-contamination between production batches.

Engineered for Demanding Operational Realities

Beyond safety, a seal must function reliably under the intense physical and chemical stresses of modern food processing.

Withstanding Aggressive Cleaning and Sterilization

Food processing facilities rely on rigorous Clean-in-Place (CIP) and Sterilize-in-Place (SIP) procedures, which use aggressive chemicals like caustics, acids, and solvents.

Unlike many elastomeric (rubber) seals that can degrade when exposed to these chemicals, PTFE's robust chemical resistance ensures it maintains its integrity, preventing seal failure and extending equipment life. It also withstands the high-pressure washdowns common in the industry.

Excelling in High-Speed Applications

Equipment such as industrial mixers, pumps, and conveyors operate at high rotational speeds. PTFE's extremely low coefficient of friction is a critical advantage here.

Low friction means less heat is generated at the sealing point, reducing wear on both the seal and the shaft. This allows for higher operational speeds without the risk of premature seal failure, boosting productivity and reliability.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal solution. Understanding their specific characteristics is key to successful implementation.

Limited Elasticity Compared to Elastomers

PTFE is a relatively rigid material and lacks the "memory" or elasticity of rubber seals. It is less forgiving of shaft imperfections, misalignment, or significant runout.

Proper shaft preparation and precise installation are more critical for PTFE seals to ensure a consistent and effective seal.

Considerations for Cold Flow (Creep)

Under sustained pressure and temperature, PTFE can be subject to "creep," a slow, permanent deformation.

Seal designs account for this property, often incorporating a metal case or energizing springs to maintain consistent sealing force over the lifetime of the component. This must be considered during the initial equipment design phase.

Making the Right Choice for Your Application

Selecting the right seal material is a decision based on balancing compliance, performance, and operational demands.

- If your primary focus is product safety and regulatory compliance: PTFE's inertness and certification to FDA, EU, and 3-A standards make it a definitive and trusted choice.

- If your primary focus is minimizing downtime from harsh cleaning: PTFE's superior resistance to aggressive CIP chemicals and high-pressure washdowns provides unmatched longevity.

- If your primary focus is performance in high-speed equipment: PTFE's low-friction properties reduce heat and wear, enabling reliable operation in demanding mixers, pumps, and conveyors.

Ultimately, choosing PTFE is an investment in operational stability, product integrity, and long-term reliability.

Summary Table:

| Key Advantage | Why It Matters for Food & Beverage |

|---|---|

| Regulatory Compliance | Meets FDA, EU, and 3-A Sanitary Standards for direct food contact. |

| Chemical Inertness | Prevents contamination; resistant to aggressive CIP/SIP chemicals. |

| Non-Stick Surface | Hygienic; easy to clean, reducing bacterial growth risk. |

| Low Friction | Enables high-speed operation in mixers and pumps with less wear. |

Ensure the purity and reliability of your food processing equipment with precision-engineered PTFE components from KINTEK.

We specialize in manufacturing high-performance PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a solution tailored to your specific hygiene and performance requirements.

Contact our experts today to discuss how our PTFE solutions can enhance your product safety and operational efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications