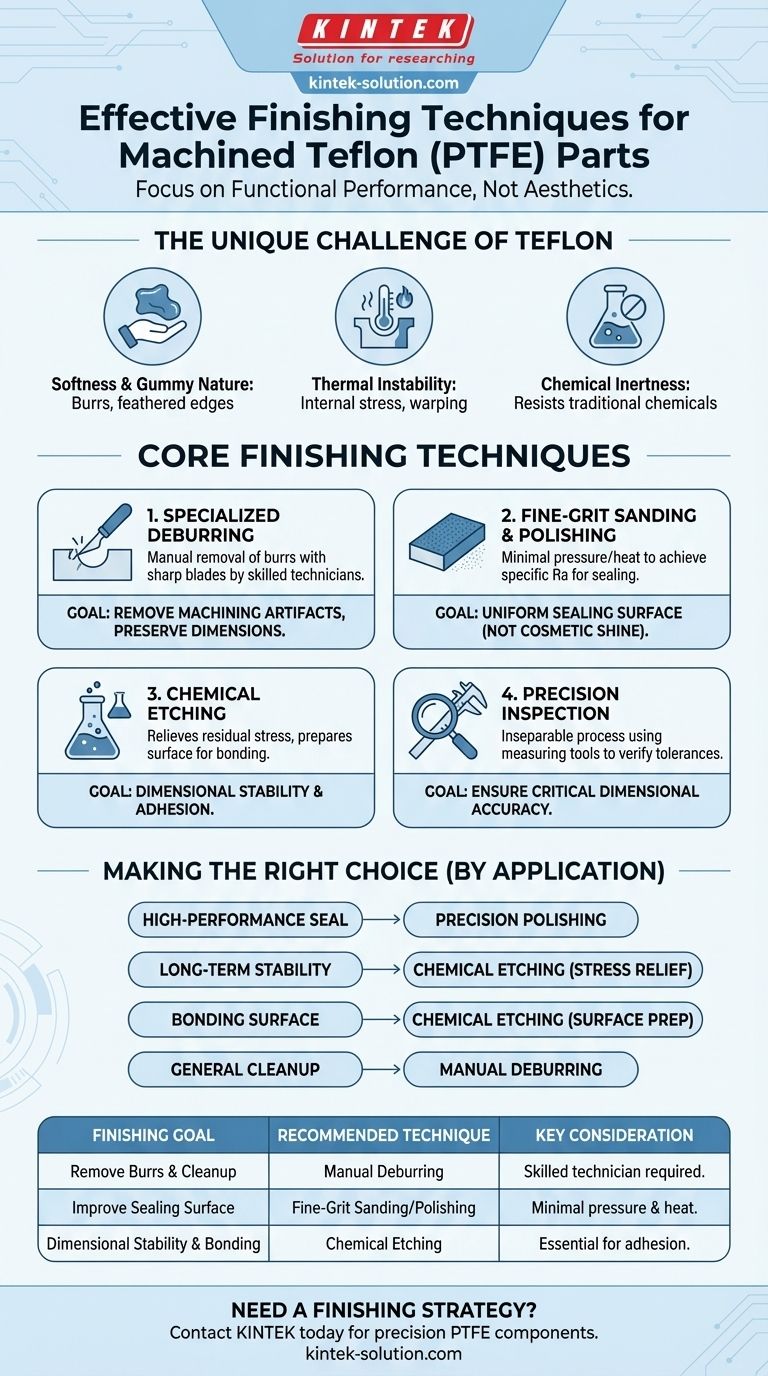

The most effective finishing techniques for machined Teflon (PTFE) parts are specialized deburring, fine-grit sanding, precision polishing, and chemical etching. Unlike metals, the goal with Teflon is not to achieve a cosmetic shine but to remove machining artifacts like burrs and relieve internal stresses while preserving the part's critical dimensional accuracy.

Finishing Teflon is a delicate process focused on functional performance, not aesthetics. The core challenge is to remove machining-induced imperfections and stresses without compromising the material's unique softness, thermal sensitivity, and tight tolerances.

Why Finishing Teflon is a Unique Challenge

Understanding Teflon's inherent properties is crucial to selecting the right finishing method. Its characteristics make it fundamentally different from metals or even other plastics.

Softness and Gummy Nature

Teflon is exceptionally soft and can be "gummy" during machining. This often results in raised burrs and feathered edges rather than clean, sharp cuts. Aggressive finishing can easily smear this material or gouge the surface, destroying the part's geometry.

Internal Stress and Thermal Instability

The heat and pressure from machining processes like milling or turning can induce internal stresses in Teflon parts. If not addressed, this stress can cause the part to warp or change dimensions over time, especially with temperature fluctuations.

Chemical Inertness

While Teflon's chemical resistance is a major advantage in its final application, it means many traditional chemical polishing agents are ineffective. However, specific etchants can be used to prepare the surface for bonding or to relieve residual stress.

Core Finishing Techniques Explained

Each finishing technique addresses a specific challenge presented by Teflon's properties. They are often used in combination to produce a functional, reliable component.

Specialized Deburring

This is the most common and critical finishing step. Due to Teflon's softness, burrs are a frequent issue. Manual deburring with a sharp blade, performed carefully by a skilled technician, is often the most reliable method to remove burrs without damaging the part surface.

Fine-Grit Sanding and Polishing

When a specific surface finish (Ra) is required, such as for a sealing surface, fine-grit sanding or precision polishing may be used. This must be done with minimal pressure and heat to avoid melting or distorting the part. The goal is a consistent, smooth surface, not a mirror finish.

Chemical Etching

Chemical etching serves a very specific purpose: relieving residual surface stress introduced during machining. This process enhances the part's dimensional stability. It is also the primary method used to prepare a Teflon surface for bonding with an adhesive.

The Role of Precision Inspection

While not a finishing method itself, thorough inspection is an inseparable part of the process. Using precision measuring tools is essential to verify that deburring, polishing, or etching has not pushed any dimensions outside of the specified tolerances.

Understanding the Trade-offs and Pitfalls

Finishing Teflon is a process of diminishing returns where over-processing can do more harm than good.

The Risk of Over-Finishing

The single biggest mistake is treating Teflon like metal. Aggressive polishing or sanding can easily remove too much material, destroying tight tolerances. It can also introduce heat, causing the part to warp and fail inspection.

Manual Control vs. Process Scalability

Manual deburring offers the highest degree of control and is often necessary for complex geometries. However, it is labor-intensive and less scalable than chemical processes. The choice depends on part complexity, volume, and the specific features that need finishing.

Designing for an Easier Finish

The need for intensive finishing can be significantly reduced during the design phase. Specifying appropriate tolerances, distributing loads to prevent creep, and designing features with generous radii will result in a cleaner machined part that requires minimal post-processing.

Making the Right Choice for Your Goal

The best finishing strategy depends entirely on the part's final application.

- If your primary focus is creating a high-performance seal: Prioritize precision polishing to achieve the specific, uniform surface finish (Ra) required for sealing.

- If your primary focus is long-term dimensional stability: Use a stress-relief process like controlled chemical etching and avoid any finishing that introduces heat.

- If your primary focus is preparing a surface for bonding: Chemical etching is the only effective method to create a bondable surface on otherwise non-stick Teflon.

- If your primary focus is general part cleanup: Careful manual deburring is the most reliable method to remove machining artifacts without altering critical dimensions.

Ultimately, a successful Teflon part is the result of a holistic approach where design, machining, and finishing are all optimized for the material's unique behavior.

Summary Table:

| Finishing Goal | Recommended Technique | Key Consideration |

|---|---|---|

| Remove Burrs & Cleanup | Manual Deburring | Requires skilled technician to avoid material damage. |

| Improve Sealing Surface | Fine-Grit Sanding/Polishing | Use minimal pressure and heat to prevent warping. |

| Dimensional Stability & Bonding Prep | Chemical Etching | Relieves internal stress; essential for adhesion. |

Need a Finishing Strategy for Your Precision Teflon Components?

At KINTEK, we specialize in machining and finishing high-performance PTFE parts for the semiconductor, medical, and laboratory industries. We understand that the right finishing technique is critical for your part's functional performance, dimensional stability, and longevity.

Our expertise ensures your Teflon seals, liners, and labware are finished to perfection, whether you require a specific surface finish for sealing, stress relief for stability, or surface preparation for bonding.

Let us apply our precision finishing knowledge to your project.

Contact KINTEK today to discuss your custom PTFE component needs, from prototypes to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries benefit from PTFE and PFA lined check valves? Ensure Safety and Purity in Harsh Processes

- What makes PTFE the preferred choice for high-speed rotary shaft seals? Unmatched Performance in Demanding Applications

- What are the uses of Polytetrafluoroethylene (PTFE) with Glass Fill? Boost Wear Resistance & Strength

- How does the chemical resistance of PTFE gaskets benefit ball valve applications? Ensure Leak-Free, Non-Contaminating Seals

- What role do PTFE expansion bellows play in vibration absorption? Isolate Equipment to Prevent System Damage

- What are PTFE envelope gaskets and how are they constructed? A Guide to Composite Sealing Technology

- What are the advantages of glass fiber filled PTFE? Boost Strength & Resist Wear

- What is the significance of PTFE's chemical inertness in instrumentation systems? Ensure Unmatched System Integrity and Accuracy