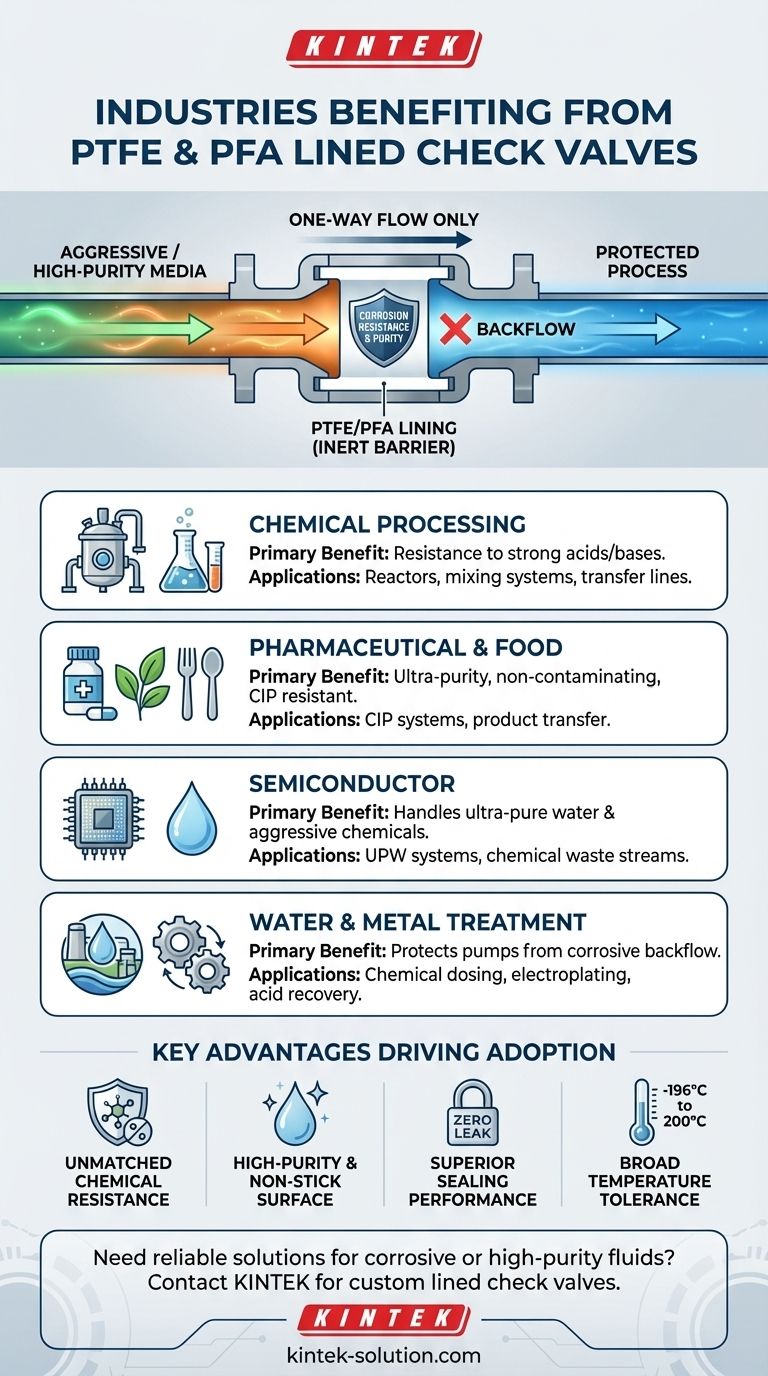

In short, industries that handle highly corrosive or high-purity fluids benefit most from PTFE and PFA lined check valves. These include the chemical processing, pharmaceutical, food and beverage, semiconductor, and water treatment sectors. The key advantage is the inert lining, which protects the valve's structural components from aggressive media, ensuring safety, preventing contamination, and extending service life.

The decision to use a PTFE or PFA lined check valve is driven not by the industry, but by the nature of the fluid being controlled. If the medium is corrosive, requires extreme purity, or both, a lined valve is almost always the superior technical choice for preventing backflow.

The Core Problem: Aggressive Media vs. Valve Integrity

Why Standard Valves Are Insufficient

Standard metal valves, even those made from stainless steel, can quickly degrade when exposed to strong acids, alkalis, salts, and other corrosive chemicals.

This corrosion leads to valve failure, dangerous leaks, and contamination of the process media. In industries where fluid purity or safety is paramount, this is an unacceptable risk.

The Role of a PTFE/PFA Lining

Polytetrafluoroethylene (PTFE) and Perfluoroalkoxy (PFA) are fluoropolymers known for their extraordinary chemical inertness.

A PTFE or PFA lining acts as a complete, non-reactive barrier between the fluid and the valve's metal body. This allows the valve to provide structural strength while the liner provides total corrosion resistance.

The Critical Function of a Check Valve

A check valve serves a single, vital purpose: to allow fluid to flow in only one direction.

It automatically prevents backflow, which is critical for protecting upstream equipment like pumps, preventing cross-contamination between lines, and ensuring process stability. Combining this function with a chemically inert lining creates a robust solution for the most demanding applications.

Key Industries and Their Specific Applications

Chemical Processing

In chemical plants, these valves are essential for safely transferring strong acids, bases, and other corrosive reactants. They are used in mixing systems, batch reactors, and transfer lines where backflow could cause hazardous reactions or damage equipment.

Pharmaceutical & Food Manufacturing

Purity is the primary concern in these industries. The non-stick, non-leaching properties of PTFE and PFA prevent the process media from being contaminated.

These valves are also resistant to the aggressive cleaning agents used in Clean-in-Place (CIP) systems, ensuring both product purity and valve longevity.

Semiconductor Production

Manufacturing microchips requires the use of ultra-pure water and highly corrosive chemicals. PTFE/PFA lined valves are critical for preventing contamination in pure water systems and for safely handling chemical waste treatment streams without valve failure.

Water Treatment and Metal Processing

Municipal and industrial water treatment facilities use a variety of corrosive chemicals for purification. Lined check valves prevent these chemicals from flowing backward and damaging pumps.

Similarly, in metal processing, they are used in applications like electroplating and acid recovery systems where aggressive chemical mixtures are common.

Key Advantages Driving Adoption

Unmatched Chemical Resistance

The primary benefit is near-universal resistance to chemical attack. This ensures the valve will not degrade, providing reliable and safe operation in the harshest environments.

High-Purity and Non-Stick Surface

The smooth, non-porous surface of PTFE/PFA resists buildup and is easy to clean. More importantly, it does not leach impurities into the fluid, making it ideal for applications demanding the highest levels of purity.

Superior Sealing Performance

Properly designed lined valves offer excellent sealing, often achieving zero leakage. This is critical for containing hazardous materials, preventing fugitive emissions, and maintaining system pressure and efficiency.

Broad Temperature Tolerance

These linings perform reliably across an exceptionally wide temperature range, from cryogenic conditions (-196°C) up to 200°C. This versatility allows them to be specified for a vast number of industrial processes without concern for temperature-related failure.

Making the Right Choice for Your Application

- If your primary focus is handling corrosive chemicals: The inert PTFE/PFA lining is your most reliable defense against corrosion, ensuring system safety and longevity.

- If your primary focus is maintaining product purity: The non-stick, non-leaching properties of a lined valve are essential to prevent contamination and meet stringent quality standards.

- If your primary focus is protecting sensitive equipment: A lined check valve provides foolproof backflow prevention while resisting the process media, safeguarding expensive upstream components.

Ultimately, choosing a lined valve is an investment in the safety, purity, and reliability of your entire fluid handling system.

Summary Table:

| Industry | Primary Benefit | Common Applications |

|---|---|---|

| Chemical Processing | Corrosion resistance to strong acids/bases | Reactors, transfer lines, mixing systems |

| Pharmaceutical & Food | Ultra-purity, non-contaminating, CIP resistant | Clean-in-Place (CIP) systems, product transfer |

| Semiconductor | Handles ultra-pure water and aggressive chemicals | Ultra-pure water systems, chemical waste streams |

| Water & Metal Treatment | Protects pumps from corrosive chemical backflow | Chemical dosing, electroplating, acid recovery |

Need a reliable check valve for corrosive or high-purity fluids?

KINTEK specializes in manufacturing high-performance PTFE and PFA components, including custom-fabricated lined check valves. We serve the semiconductor, medical, laboratory, and industrial sectors by prioritizing precision and durability. Our custom fabrication capabilities ensure you get the perfect solution, from prototypes to high-volume orders.

Let us help you protect your process and equipment. Contact KINTEK today for a quote or to discuss your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications