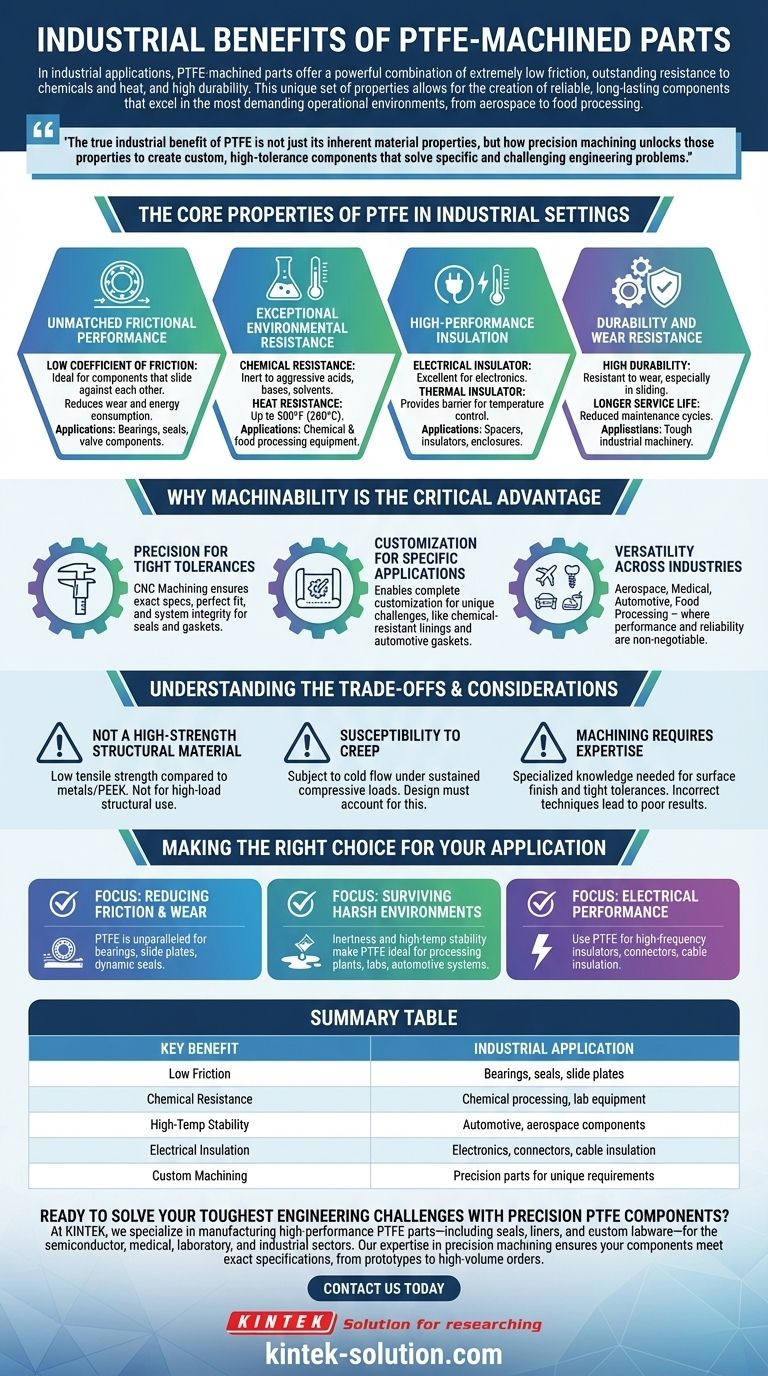

In industrial applications, PTFE-machined parts offer a powerful combination of extremely low friction, outstanding resistance to chemicals and heat, and high durability. This unique set of properties allows for the creation of reliable, long-lasting components that excel in the most demanding operational environments, from aerospace to food processing.

The true industrial benefit of PTFE is not just its inherent material properties, but how precision machining unlocks those properties to create custom, high-tolerance components that solve specific and challenging engineering problems.

The Core Properties of PTFE in Industrial Settings

Understanding the fundamental characteristics of Polytetrafluoroethylene (PTFE) reveals why it is a cornerstone material for high-performance applications. These properties work in concert to deliver reliability where other materials fail.

Unmatched Frictional Performance

PTFE possesses one of the lowest coefficients of friction of any solid material. This makes it an ideal choice for components that slide against each other.

This "non-stick" characteristic significantly reduces wear and energy consumption in moving parts, extending the life of assemblies like bearings, seals, and valve components.

Exceptional Environmental Resistance

The material is nearly inert, offering exceptional chemical resistance against a vast range of aggressive acids, bases, and solvents. This makes it invaluable for equipment used in chemical and food processing.

Furthermore, PTFE maintains its integrity across a wide temperature range, with a high heat resistance of up to 500°F (260°C). It is also non-corrosive, ensuring stability in harsh industrial settings.

High-Performance Insulation

PTFE is an excellent electrical insulator, making it a critical material for manufacturing spacers, insulators, and enclosures in the electronics industry.

It also serves as an effective thermal insulator, providing a barrier in applications where temperature control is crucial.

Durability and Wear Resistance

Components machined from PTFE exhibit high durability and resistance to wear, especially in sliding applications.

This inherent toughness and impact strength contribute to a longer service life and reduced maintenance cycles for the machinery in which they are installed.

Why Machinability is the Critical Advantage

While the raw properties of PTFE are impressive, its true value is realized through precision manufacturing. The ability to machine the material to exact specifications is what transforms it from a useful polymer into an engineered solution.

Precision for Tight Tolerances

CNC machining allows for the creation of PTFE parts with extremely tight tolerances, which is critical for performance.

This precision ensures that components like seals and gaskets create a perfect fit, preventing leaks and maintaining system integrity without warping the material during fabrication.

Customization for Specific Applications

Machinability enables complete customization to meet unique operational challenges.

Engineers can design specialized parts, such as chemical-resistant tank linings, custom automotive gaskets, or unique laboratory instrument components, that are perfectly optimized for their intended function.

Versatility Across Industries

The combination of elite properties and customizability makes PTFE a versatile solution across numerous sectors.

Common applications are found in aerospace (seals), medical (implants), automotive (gaskets), and food processing (non-stick surfaces), where performance and reliability are non-negotiable.

Understanding the Trade-offs and Considerations

To use PTFE effectively, it is essential to recognize its limitations. No material is a universal solution, and PTFE is best applied where its unique strengths are the primary requirement.

Not a High-Strength Structural Material

While durable, PTFE has relatively low tensile strength compared to metals or other engineering polymers like PEEK. It should not be used for high-load, structural applications.

Susceptibility to Creep

Under sustained compressive loads, PTFE can be subject to "creep" or cold flow, where the material slowly deforms over time. This must be accounted for in the design of components like seals and gaskets.

Machining Requires Expertise

Achieving a clean surface finish and holding tight tolerances with PTFE requires specialized knowledge. Its softness and thermal properties mean that incorrect machining techniques can lead to poor results.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary operational goal.

- If your primary focus is reducing friction and wear: PTFE is an unparalleled choice for bearings, slide plates, and dynamic seals where smooth motion is critical.

- If your primary focus is surviving harsh environments: Its chemical inertness and high-temperature stability make PTFE ideal for components in chemical processing plants, laboratories, and automotive systems.

- If your primary focus is electrical performance: Use PTFE for high-frequency insulators, connectors, and cable insulation where signal integrity and safety are paramount.

By leveraging the distinct advantages of machined PTFE, you can engineer components that deliver superior performance and longevity in their specific roles.

Summary Table:

| Key Benefit | Industrial Application |

|---|---|

| Low Friction | Bearings, seals, slide plates |

| Chemical Resistance | Chemical processing, lab equipment |

| High-Temp Stability | Automotive, aerospace components |

| Electrical Insulation | Electronics, connectors, cable insulation |

| Custom Machining | Precision parts for unique requirements |

Ready to solve your toughest engineering challenges with precision PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE parts—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision machining ensures your components meet exact specifications, from prototypes to high-volume orders.

Contact us today to discuss how our custom PTFE solutions can enhance your application's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability