In short, PTFE expansion bellows act as flexible dampeners within a rigid piping system. Their core function is to absorb and isolate mechanical vibrations generated by equipment like pumps and compressors. This prevents vibrational energy from traveling through the pipeline, safeguarding both the pipes and connected components from damaging stress and fatigue.

The primary role of a PTFE expansion bellow is not just to absorb vibration, but to serve as a critical decoupling point in a piping system. By isolating dynamic equipment, it protects the entire infrastructure from the cumulative damage of cyclic stress, significantly enhancing system longevity and reliability.

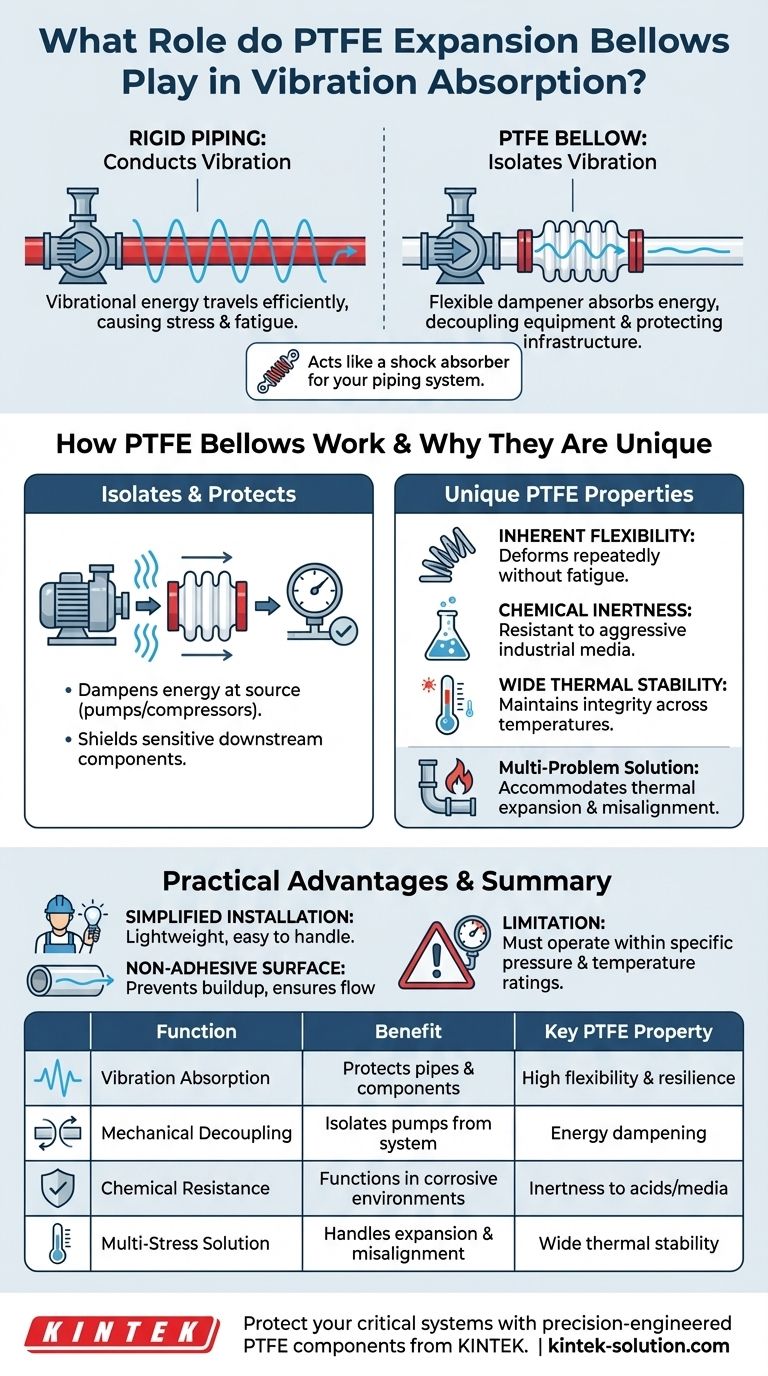

How PTFE Bellows Isolate System Vibration

A rigid piping system is an excellent conductor of vibration. Any energy introduced at one point travels efficiently throughout its length. PTFE bellows are engineered to interrupt this path.

The Principle of Mechanical Decoupling

A PTFE bellow introduces a segment of high flexibility into an otherwise rigid structure. When vibrational waves encounter the bellow, its convoluted, flexible form absorbs the energy, much like a shock absorber in a car's suspension.

This act of absorption effectively decouples the vibration source (the pump) from the rest of the piping network.

Dampening Energy from Dynamic Equipment

Machinery such as pumps, engines, and compressors inherently produce vibrations during operation. While often low in amplitude, this energy is constant and creates cyclic stress on welds, flanges, and fittings.

PTFE bellows are placed near this equipment to dampen these vibrations at the source, preventing them from propagating and causing fatigue-related failures over time.

Protecting Sensitive Components

The benefits extend beyond protecting the pipes themselves. Sensitive instruments, valve assemblies, and critical connections downstream are shielded from the constant wear of vibration. This improves their accuracy, reliability, and service life.

Why PTFE is Uniquely Suited for This Role

While other flexible materials exist, PTFE (Polytetrafluoroethylene) offers a combination of properties that make it a superior choice for demanding industrial applications.

Inherent Flexibility and Resilience

The molecular structure of PTFE allows it to flex and deform repeatedly without work-hardening or degrading. This ensures it can perform its vibration-dampening function reliably over millions of cycles.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and corrosive agents. This allows it to be used in aggressive media environments where a rubber or metallic bellow would quickly fail.

Wide Thermal Stability

The material maintains its flexibility and structural integrity across a broad range of temperatures. This means the same component can handle vibrations in systems that experience significant thermal cycling.

A Multi-Problem Solution

The same flexibility that absorbs vibration also accommodates thermal expansion and contraction, slight pipe misalignments, and other system stresses. A single PTFE bellow often solves multiple challenges simultaneously.

Understanding the Practical Advantages and Trade-offs

Integrating any component requires a clear-eyed view of its benefits and limitations. PTFE bellows offer significant advantages but must be applied correctly.

Simplified Installation

Compared to metallic expansion joints, PTFE bellows are exceptionally lightweight. This makes them easier and safer to handle and install, often without requiring specialized lifting equipment, which reduces labor costs and downtime.

Non-Adhesive Surface

PTFE's famous non-stick properties prevent process media from building up on the internal surfaces. This is critical for maintaining flow efficiency and preventing clogs, particularly in slurry or high-purity applications.

Limitation: Pressure and Temperature Ratings

Like any engineered component, PTFE bellows have specific design limits for pressure and temperature. Exceeding these ratings can lead to failure. It is critical to select a bellow rated appropriately for the system's operational parameters.

Not a Substitute for Proper Anchoring

A bellow provides flexibility; it does not provide structural support. The piping system must still be independently and correctly anchored and guided to prevent thrust forces from damaging the bellow or the system.

Making the Right Choice for Your System

Choosing to integrate a PTFE bellow depends on identifying the primary stressor you need to manage in your piping system.

- If your primary focus is protecting equipment from pump vibration: A PTFE bellow is the ideal solution to isolate the source and prevent fatigue damage downstream.

- If your primary focus is handling thermal expansion in a corrosive line: The bellow's combination of flexibility and chemical inertness makes it a superior choice over rigid pipe loops or less-resistant materials.

- If your primary focus is reducing installation time and system maintenance: The lightweight, non-stick, and durable nature of PTFE provides a clear operational advantage.

Ultimately, integrating a PTFE expansion bellow is a strategic investment in the long-term reliability and integrity of your entire piping system.

Summary Table:

| Function | Benefit | Key Property of PTFE |

|---|---|---|

| Vibration Absorption | Protects pipes and components from fatigue | High flexibility and resilience |

| Mechanical Decoupling | Isolates pumps/compressors from the system | Ability to absorb and dampen energy |

| Chemical Resistance | Functions in corrosive environments | Inertness to acids and aggressive media |

| Multi-Stress Solution | Handles thermal expansion and misalignment | Wide thermal stability and flexibility |

Protect your critical piping systems with precision-engineered PTFE components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE expansion bellows are designed to absorb vibration, resist corrosion, and enhance the longevity of your equipment. We specialize in creating solutions from prototypes to high-volume orders, ensuring your systems run reliably.

Contact KINTEK today to discuss your specific application needs and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- How is the bolt length determined for PTFE lined butterfly valves? Ensure a Safe, Leak-Proof Seal

- What lubrication characteristics does PTFE offer for mechanical seals? Achieve Oil-Free, Low-Friction Sealing

- What are the different grades of PTFE used in rotary shaft seals? Choose the Right Filler for Peak Performance

- How does the price of PTFE sliding pads compare to regular rubber bearings? A Guide to High-Performance vs. Standard Components

- What are the key advantages of PTFE lip seals? Superior Performance in Extreme Conditions

- How does the quality of Teflon bearings compare to traditional bearings? Superior Performance in Harsh Environments

- How can deformation of PTFE during machining be minimized? Master Precision with Sharp Tools & Thermal Control

- What are the benefits of PTFE's flexibility compared to rigid plastics? Superior Sealing in Dynamic Applications