The primary benefit of PTFE's flexibility is its ability to create and maintain a superior seal in dynamic applications. Unlike rigid plastics, PTFE can conform to imperfect surfaces and adapt to fluctuations in pressure and temperature, ensuring a consistent and reliable barrier where materials like PEEK or Acetal would fail.

The choice between PTFE and a rigid plastic is not about inherent superiority, but about aligning a material's core properties with the specific demands of an application. PTFE's flexibility is its key mechanical advantage, but its true value emerges when combined with its extreme chemical and thermal resilience.

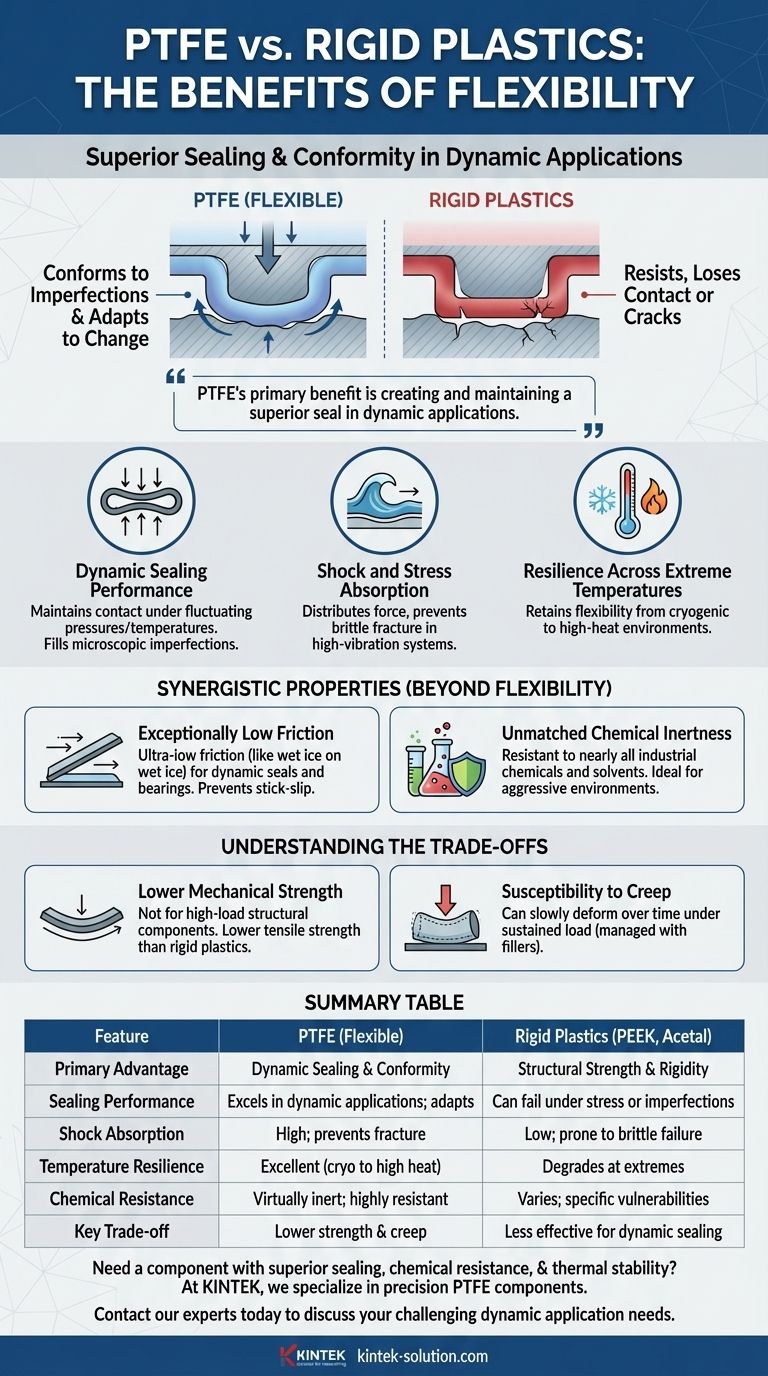

The Core Advantage: Conforming to Imperfection and Change

The fundamental difference between a flexible and a rigid material lies in how it responds to external forces and environmental shifts. PTFE is engineered to yield and adapt, whereas rigid plastics are designed to resist and hold their form.

Dynamic Sealing Performance

PTFE excels in applications like gaskets, O-rings, and valve seats precisely because it is not rigid. It can be compressed to fill microscopic imperfections on a mating surface, creating a tight seal.

As operating pressures and temperatures change, PTFE expands or contracts with the system, maintaining constant contact and preventing leaks. A rigid plastic in the same scenario might lose contact or crack under the stress.

Shock and Stress Absorption

Flexibility allows PTFE to absorb impacts and vibrations that would fracture more brittle plastics. This property is critical in high-vibration machinery or systems subject to physical shock.

Instead of concentrating stress at a single point, PTFE distributes the force across its structure, preventing catastrophic failure.

Resilience Across Extreme Temperatures

Crucially, PTFE retains its useful flexibility across an exceptionally wide temperature range. It does not become brittle at cryogenic temperatures or excessively soft in high-heat environments.

This consistent performance ensures its sealing and shock-absorbing capabilities remain reliable under conditions where most other polymers would degrade or fail.

Beyond Flexibility: Synergistic Properties

While flexibility is a key mechanical trait, it is PTFE's combination of other elite properties that makes it an indispensable material in so many demanding industries.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This non-stick characteristic is vital for sliding applications like bearings or dynamic seals.

This property reduces wear on moving parts, lowers the energy required to operate machinery, and prevents the "stick-slip" phenomenon that can cause jerky motion and component failure.

Unmatched Chemical Inertness

PTFE is virtually inert, meaning it is resistant to nearly all industrial chemicals, solvents, and corrosive agents. This is a significant advantage over high-performance plastics like PEEK or Nylon, which have known chemical vulnerabilities.

This allows PTFE components to be used in the most aggressive chemical processing, medical, and laboratory environments without risk of degradation.

Understanding the Trade-offs

No material is perfect for every situation. Choosing PTFE for its flexibility means accepting certain trade-offs compared to more rigid engineering plastics.

Lower Mechanical Strength

The primary trade-off for flexibility is lower tensile strength and rigidity. PTFE is not suitable for high-load structural components that must resist bending or deformation under force.

For applications requiring high stiffness and load-bearing capacity, a rigid plastic like Acetal or PEEK is the superior choice.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time—a phenomenon known as "creep." While this can be managed, rigid plastics exhibit far less creep and offer better long-term dimensional stability under load.

The Role of Fillers

The properties of PTFE can be modified by adding fillers like glass, carbon, or bronze. These fillers can increase stiffness, improve wear resistance, and reduce creep, helping to bridge the gap between pure PTFE and more rigid plastics for specific applications.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary operational goal.

- If your primary focus is dynamic sealing in harsh environments: Choose PTFE for its unmatched combination of flexibility, chemical inertness, and wide temperature tolerance.

- If your primary focus is a high-load structural component: Choose a rigid plastic like PEEK or Acetal for its superior strength, stiffness, and resistance to creep.

- If your primary focus is a low-friction, non-stick surface: PTFE is the definitive choice, especially in applications involving moving parts or requiring chemical and thermal stability.

Ultimately, understanding these core principles empowers you to select the material that is perfectly suited to the task at hand.

Summary Table:

| Feature | PTFE (Flexible) | Rigid Plastics (e.g., PEEK, Acetal) |

|---|---|---|

| Primary Advantage | Dynamic Sealing & Conformity | Structural Strength & Rigidity |

| Sealing Performance | Excels in dynamic applications; adapts to pressure/temperature changes | Can fail under stress or with surface imperfections |

| Shock Absorption | High; distributes force to prevent fracture | Low; more prone to brittle failure |

| Temperature Resilience | Excellent performance from cryogenic to high heat | Performance can degrade at extremes |

| Chemical Resistance | Virtually inert; resistant to most chemicals | Varies; can have specific vulnerabilities |

| Key Trade-off | Lower mechanical strength & susceptibility to creep | Less effective for dynamic sealing and conformity |

Need a component that demands superior sealing, chemical resistance, and thermal stability?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures your parts perfectly match your application's requirements, from prototype to high-volume production.

Contact our experts today to discuss how our PTFE solutions can solve your most challenging dynamic application needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers