PTFE offers exceptional lubrication for mechanical seals due to its status as the solid material with the lowest known coefficient of friction. This, combined with its complete lack of surface adhesion, allows it to function as a premier oil-free lubricating seal, reducing wear and improving operational efficiency in demanding environments.

The core value of PTFE in sealing is not just its self-lubricating nature, but the powerful combination of this property with its near-universal chemical inertness. This allows it to solve sealing challenges where traditional lubricants would fail or contaminate the system.

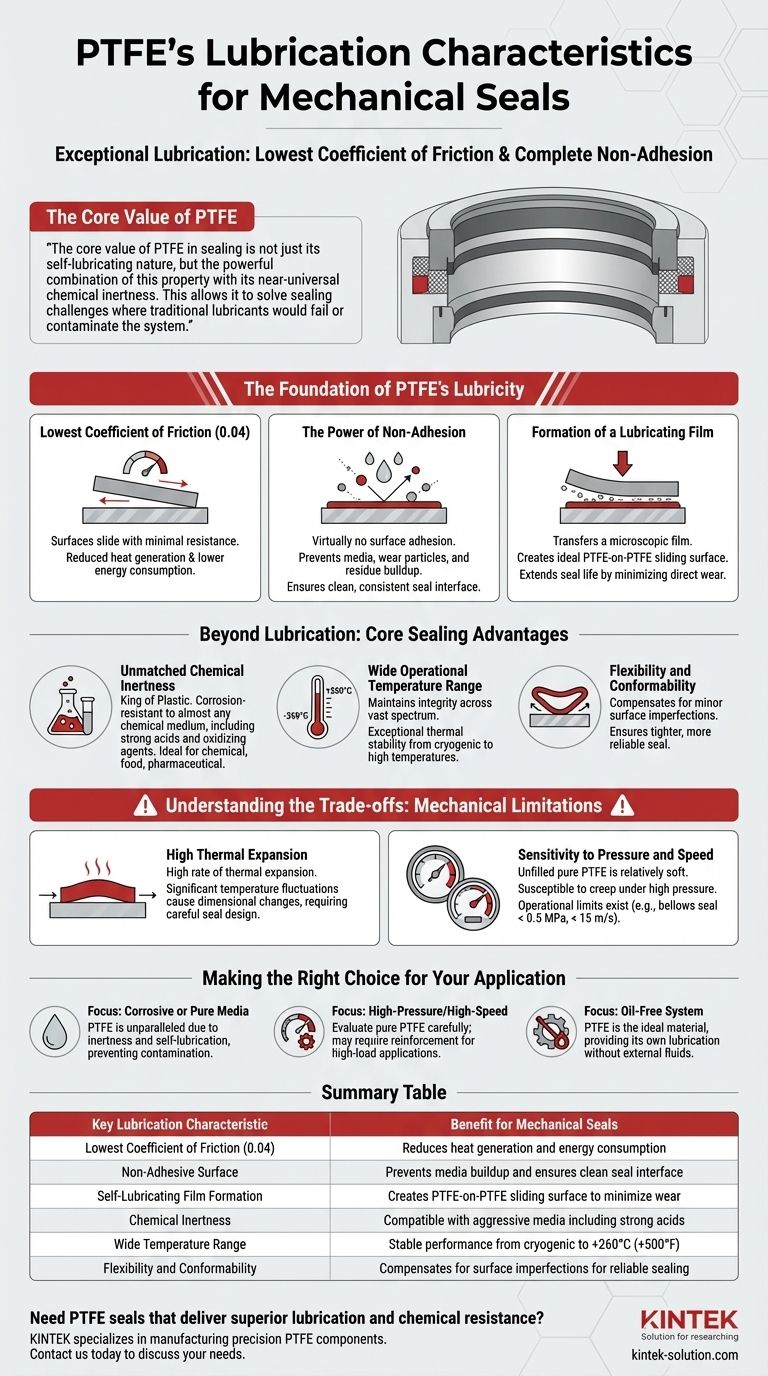

The Foundation of PTFE's Lubricity

To understand PTFE's role, we must first examine the specific properties that make it an elite lubricating material for mechanical seals.

The Lowest Coefficient of Friction

PTFE has a coefficient of friction of just 0.04, the lowest of any solid material. This exceptionally low value means that surfaces slide against each other with minimal resistance.

This property directly translates to reduced heat generation at the seal face and lower energy consumption for the machinery.

The Power of Non-Adhesion

Often known for its "non-stick" qualities, PTFE has virtually no surface adhesion. This prevents media, wear particles, or other residues from building up on the seal faces.

As a result, the seal maintains a clean, consistent interface, which is critical for preventing leaks and ensuring a long operational life.

Formation of a Lubricating Film

During operation, PTFE transfers a microscopic film of its own material onto the mating seal face. This creates an ideal PTFE-on-PTFE sliding surface.

This self-lubricating film is a key mechanism that extends seal life by minimizing direct wear on the primary components.

Beyond Lubrication: Core Sealing Advantages

While its lubricity is paramount, PTFE's other inherent characteristics make it uniquely suited for challenging sealing applications.

Unmatched Chemical Inertness

Known as the "king of plastic," PTFE is one of the most corrosion-resistant materials available. It is compatible with almost any chemical medium, including strong acids and strong oxidizing agents.

This makes it the default choice for applications in the chemical processing, food, and pharmaceutical industries where media purity and corrosion are primary concerns.

Wide Operational Temperature Range

PTFE maintains its integrity across a vast temperature spectrum, from cryogenic conditions up to +260°C (+500°F). While specific seal designs may have narrower operating windows (e.g., -10°C to +100°C), the material itself provides exceptional thermal stability.

Flexibility and Conformability

The material's flexibility allows it to compensate for minor surface imperfections on shafts or housings. This conformability ensures a tighter, more reliable seal, even in equipment that isn't perfectly machined.

Understanding the Trade-offs: Mechanical Limitations

No material is perfect. Acknowledging PTFE's limitations is crucial for successful application and avoiding seal failure.

High Thermal Expansion

PTFE has a high rate of thermal expansion. Significant temperature fluctuations will cause the material to change dimensions, which must be accounted for in the seal design to maintain proper face loading and prevent leaks.

Sensitivity to Pressure and Speed

Unfilled, pure PTFE is a relatively soft material. In applications with high pressure, it can be susceptible to "creep" or permanent deformation.

Its operational limits are often constrained by these properties. For example, a typical bellows seal design might be rated for pressures below 0.5 MPa and speeds under 15 m/s.

Making the Right Choice for Your Application

Selecting the right seal material requires balancing its benefits against the demands of the system.

- If your primary focus is sealing highly corrosive or pure media: PTFE is an unparalleled choice due to its chemical inertness and self-lubricating nature, which prevents media contamination.

- If your primary focus is high-pressure or high-speed dynamics: The mechanical softness and thermal expansion of pure PTFE must be carefully evaluated, as it may not be suitable for high-load applications without reinforcement.

- If your primary focus is creating an oil-free system: PTFE is the ideal material, as it provides its own lubrication without requiring any external fluids.

Ultimately, understanding both PTFE's elite lubricity and its mechanical constraints is the key to deploying it successfully in your critical sealing systems.

Summary Table:

| Key Lubrication Characteristic | Benefit for Mechanical Seals |

|---|---|

| Lowest Coefficient of Friction (0.04) | Reduces heat generation and energy consumption |

| Non-Adhesive Surface | Prevents media buildup and ensures clean seal interface |

| Self-Lubricating Film Formation | Creates PTFE-on-PTFE sliding surface to minimize wear |

| Chemical Inertness | Compatible with aggressive media including strong acids |

| Wide Temperature Range | Stable performance from cryogenic to +260°C (+500°F) |

| Flexibility and Conformability | Compensates for surface imperfections for reliable sealing |

Need PTFE seals that deliver superior lubrication and chemical resistance?

KINTEK specializes in manufacturing precision PTFE components (seals, liners, labware) for semiconductor, medical, laboratory, and industrial applications. Our custom fabrication services—from prototypes to high-volume orders—ensure you get the exact sealing solution for your demanding environment.

Contact us today to discuss how our PTFE seals can enhance your system's performance and reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What temperature range can PTFE operate within? From Cryogenic -200°C to High-Temp +260°C

- What are the applications of ultra-thin PTFE washers (0.03mm – 0.1mm)? Solve Microscopic Engineering Challenges

- What makes PTFE slide bearings more space and weight efficient? Replace Complex Mechanics with a Simple, Lightweight Pad

- How do you use a Teflon sheet for heat press applications? Protect Your Projects and Equipment

- How do PTFE lined valves provide excellent chemical resistance? The Ultimate Guide to Inert Fluid Handling

- What are the overall benefits of PTFE spring energized seals for oil and gas operations? Achieve Unmatched Reliability in HPHT Environments

- How are PTFE guide strips used in the chemical and pharmaceutical industries? Essential for Sealing and Purity

- What types of PTFE-lined bearings are available? Find the Right Bearing for Your Load and Motion Needs