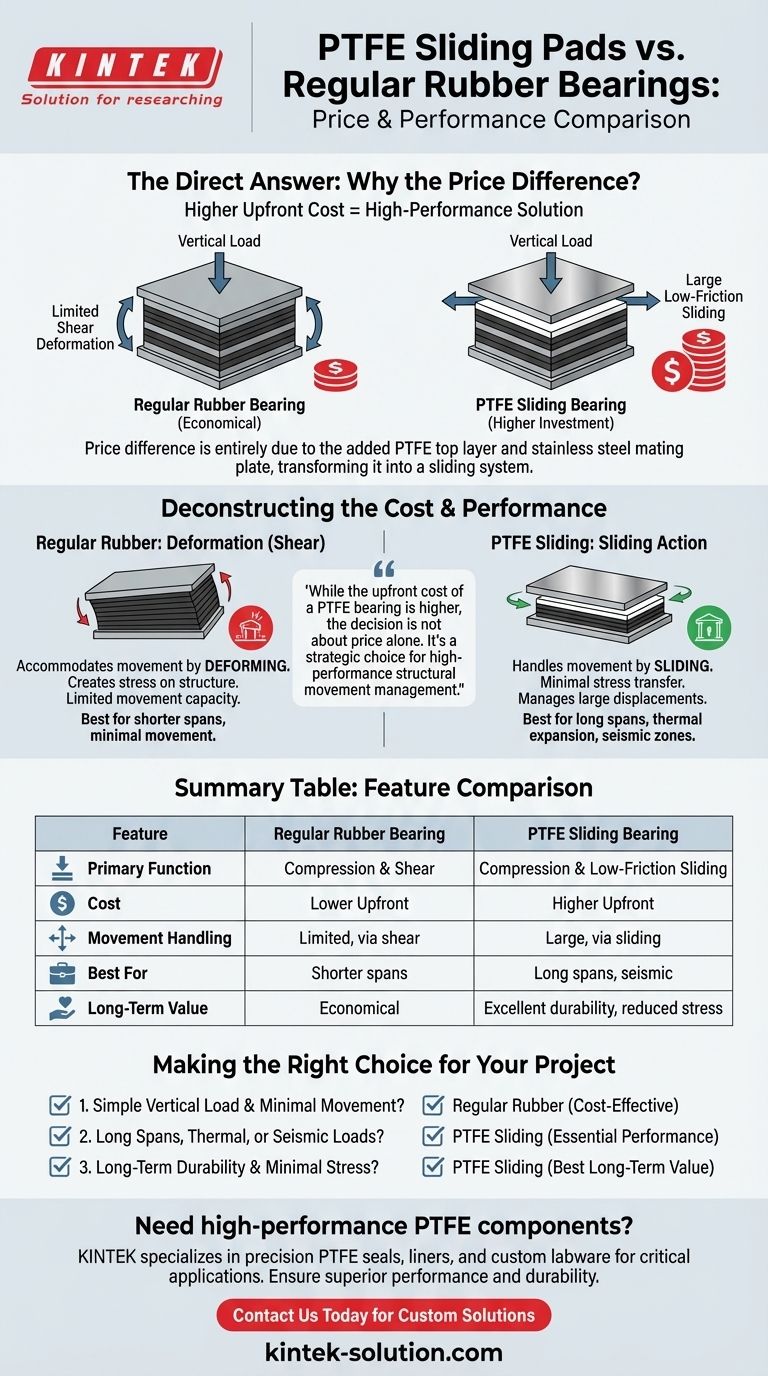

The direct answer is clear: PTFE sliding pads are more expensive than regular elastomeric rubber bearings. This price difference is entirely due to the addition of a Polytetrafluoroethylene (PTFE) top layer, which is bonded to the core rubber pad.

While the upfront cost of a PTFE bearing is higher, the decision is not about price alone. It's a strategic choice between a standard component and a high-performance solution designed to manage significant structural movement.

Deconstructing the Cost: Base Pad vs. Sliding System

The price difference is rooted in the functional design of each bearing. One is a simple block designed for compression and shear, while the other is an engineered system for sliding.

The Foundation: Laminated Rubber

Both regular and PTFE bearings start with the same core component: a laminated elastomeric rubber pad. This pad is made of layers of rubber reinforced with steel plates.

Its primary job is to support immense vertical loads from the structure above. It also accommodates minor horizontal movement through the deformation (shear) of the rubber itself.

The Differentiator: The PTFE Sliding Surface

The extra cost of a PTFE sliding pad comes from adding a low-friction PTFE layer and a corresponding stainless steel mating plate.

This addition fundamentally changes how the bearing handles movement. It transforms the component from a simple deformable pad into a true sliding system.

Performance: Why the PTFE Layer Justifies the Cost

The higher price buys a higher level of performance, specifically in managing horizontal displacement from forces like thermal expansion, shrinkage, or seismic activity.

How Regular Rubber Bearings Work

A standard elastomeric bearing accommodates horizontal movement by deforming, or shearing. This creates stress on the bearing, the anchor bolts, and the substructure itself.

There is a physical limit to how much a rubber bearing can deform before its integrity is compromised. This makes it suitable for shorter spans with limited expected movement.

How PTFE Sliding Bearings Work

A PTFE sliding bearing handles large horizontal movements by allowing a polished stainless steel plate to slide across the low-friction PTFE surface.

This sliding action places minimal stress on the underlying structure. The rubber pad beneath still absorbs vertical loads and rotations, but the major horizontal forces are managed by the slide, not by shear. This is critical for long-span bridges or structures in seismically active zones.

Understanding the Trade-offs

Choosing between these two options involves weighing upfront investment against long-term structural integrity and performance requirements.

The Upfront Cost Factor

For projects with tight budgets and simple structural demands where horizontal movement is minimal, a regular rubber bearing is often the most economical and perfectly adequate choice.

The Long-Term Value Proposition

The higher initial cost of a PTFE bearing is an investment in durability. By efficiently managing horizontal forces, it reduces stress on the entire structure, which contributes to a longer service life and requires virtually no maintenance.

The references note its "excellent performance," "simple structure," and durability, which are the core drivers of its value in demanding applications like the bridge industry.

Making the Right Choice for Your Project

The decision should be based on the specific engineering demands of your structure.

- If your primary focus is managing a simple vertical load with minimal horizontal movement: A regular elastomeric rubber bearing is the most cost-effective solution.

- If your project involves long spans, significant thermal expansion, or potential seismic loads: The superior sliding performance of a PTFE bearing is essential and justifies the additional cost.

- If long-term durability and minimizing stress on the overall structure are critical priorities: A PTFE sliding pad provides the best long-term value and engineering performance.

Ultimately, selecting the correct bearing is about matching the component's capabilities to the structural demands of the project.

Summary Table:

| Feature | Regular Rubber Bearing | PTFE Sliding Bearing |

|---|---|---|

| Primary Function | Compression & Shear Deformation | Compression & Low-Friction Sliding |

| Cost | Lower Upfront Cost | Higher Upfront Cost |

| Movement Handling | Limited horizontal movement via rubber shear | Large horizontal movement via sliding action |

| Best For | Shorter spans, minimal movement | Long spans, thermal expansion, seismic zones |

| Long-Term Value | Economical for simple applications | Excellent durability, reduces structural stress |

Need high-performance PTFE components for your critical applications?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your project benefits from superior material performance and durability.

Contact us today to discuss your custom fabrication needs, from prototypes to high-volume orders, and let our solutions bring lasting value to your designs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability