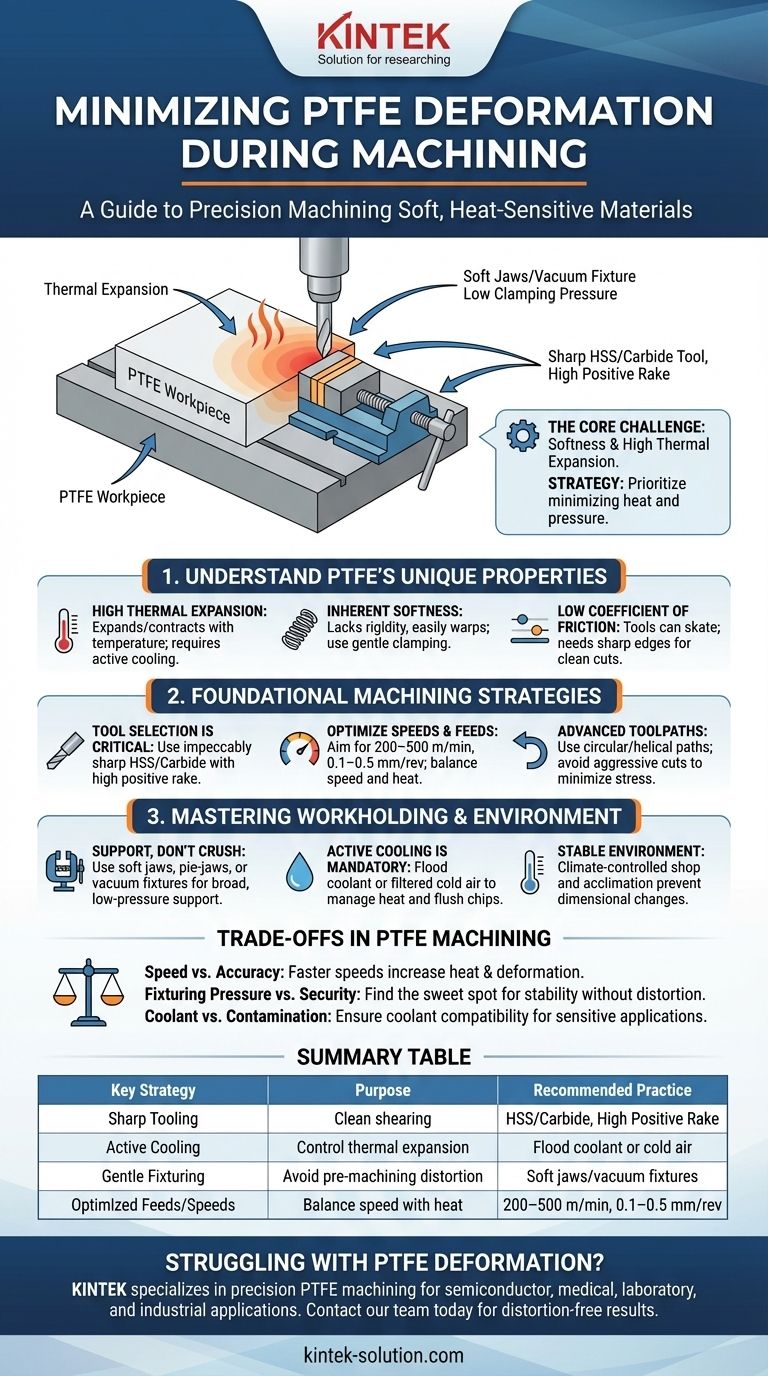

To minimize the deformation of PTFE during machining, you must use extremely sharp tools, manage heat with coolants, and secure the workpiece with fixtures that provide broad support without excessive clamping pressure. The key is to treat the material with finesse, as its inherent softness and high rate of thermal expansion make it prone to distortion under heat and mechanical stress.

The core challenge in machining PTFE is not its hardness, but its softness and high thermal expansion. Success depends on a strategy that prioritizes minimizing heat and pressure at every stage, from clamping and cutting to the final pass.

Understanding PTFE's Unique Machining Challenges

Before applying solutions, it's critical to understand the material's properties. PTFE's unique characteristics are precisely what make it both valuable and difficult to machine accurately.

High Coefficient of Thermal Expansion

PTFE expands and contracts significantly with temperature changes. Heat generated during cutting can cause the material to deform, leading to inaccurate dimensions once it cools.

This property makes active cooling not just a best practice, but a necessity for maintaining tight tolerances.

Inherent Softness and Lack of Rigidity

Unlike metals, PTFE lacks rigidity and can easily be compressed or warped. Excessive clamping pressure from a standard vise will distort the workpiece before the first cut is even made.

This softness also means the material can "push away" from the cutting tool rather than shearing cleanly, especially if the tool is dull.

Low Coefficient of Friction

While beneficial in its final application, PTFE's slipperiness means cutting tools can skate or rub if not extremely sharp, generating friction and heat instead of a clean chip.

Foundational Machining Strategies

Controlling deformation requires a systematic approach that addresses tooling, machine settings, and cutting strategy.

The Critical Role of Tool Selection

Your cutting tools must be impeccably sharp. A dull edge will plow through the material, creating heat and stress, rather than shearing it.

High-Speed Steel (HSS) or Carbide tools with a high positive rake and a sharp, ground cutting edge are ideal for producing a clean slicing action.

Optimizing Speeds and Feeds

While PTFE can be cut quickly, the goal is to balance speed with heat generation. High speeds can cause the material to melt or deform.

Aim for cutting speeds between 200–500 m/min and feed rates of 0.1–0.5 mm/rev. Always start conservatively and adjust based on the quality of the cut and chip formation.

Advanced Toolpath Considerations

How the tool moves through the material is as important as its speed. Avoid aggressive, full-width cuts that place significant stress on the part.

Use circular or helical toolpaths to minimize vibrations and ensure more even material removal. For thin sections, use multiple shallow passes instead of one deep one.

Mastering Workholding and Environmental Control

How you hold the workpiece and manage the surrounding environment is often the deciding factor between a successful part and a failed one.

The Principle of "Support, Don't Crush"

The primary goal of fixturing PTFE is to provide maximum support with minimal clamping pressure.

Standard chucks or vises are often unsuitable. Instead, use custom-molded soft jaws, pie-jaws, or vacuum fixtures that distribute holding force across a larger surface area without causing distortion.

The Necessity of Active Cooling

Coolant is mandatory for managing thermal expansion. A steady flood of coolant directed at the cutting edge will carry away heat, stabilize the workpiece, and help flush away chips.

For applications requiring high purity, filtered air can also serve as an effective coolant.

Maintaining a Stable Environment

Because PTFE is so sensitive to temperature, machining it in a climate-controlled environment helps ensure dimensional stability throughout the process.

Allow the material to acclimate to the shop's temperature before machining to prevent changes in size during the operation.

Understanding the Trade-offs

Every decision in machining PTFE involves balancing competing factors. Acknowledging these trade-offs is key to developing a reliable process.

Speed vs. Dimensional Accuracy

Pushing for faster cycle times by increasing cutting speeds will almost always generate more heat. This directly compromises dimensional accuracy due to thermal expansion. For tight-tolerance work, prioritize a cooler, slower cut.

Fixturing Pressure vs. Security

This is the central dilemma of workholding. Too little pressure and the part may shift or vibrate during the cut, ruining the finish. Too much pressure and the part deforms before you even begin. This is why specialized, full-contact fixtures are so effective.

Coolant Use vs. Part Contamination

While coolant is essential for thermal control, the type of coolant can be a factor for parts used in medical, food, or electronics industries. In these cases, ensuring coolant compatibility or using clean, cold air may be required.

Making the Right Choice for Your Goal

Your specific objective should guide your machining strategy.

- If your primary focus is maximum dimensional accuracy: Prioritize aggressive cooling and conservative speeds and feeds, allowing the part to remain thermally stable.

- If your primary focus is a high-quality surface finish: Ensure your cutting tools are perfectly sharp with a high positive rake and use a light, final "spring pass" to clean up any material deflection.

- If your primary focus is machining thin-walled or delicate parts: Use specialized vacuum or custom-cast fixtures and employ toolpaths that minimize cutting forces, such as helical interpolation.

Ultimately, successful PTFE machining is a discipline of control, where managing heat and pressure is the key to achieving precision.

Summary Table:

| Key Strategy | Purpose | Recommended Practice |

|---|---|---|

| Sharp Tooling | Clean shearing, minimal friction | Use HSS/Carbide tools with high positive rake |

| Active Cooling | Control thermal expansion | Flood coolant or cold air directed at cut |

| Gentle Fixturing | Avoid pre-machining distortion | Use soft jaws, pie-jaws, or vacuum fixtures |

| Optimized Feeds/Speeds | Balance speed with heat generation | 200–500 m/min speed, 0.1–0.5 mm/rev feed |

Struggling with PTFE deformation in your components? KINTEK specializes in precision PTFE machining for semiconductor, medical, laboratory, and industrial applications. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your parts meet exact tolerances without compromise. Contact our team today to discuss your project requirements and achieve distortion-free results.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application