The primary advantages of PTFE lip seals stem from their fundamental material properties, which allow them to operate reliably in conditions that would cause conventional elastomeric seals to fail. They excel in applications involving extreme temperatures, high pressures, aggressive chemicals, and high surface speeds, offering exceptional durability where standard seals cannot.

PTFE lip seals are not a simple upgrade from rubber seals; they are a specialized engineering solution. Their true advantage lies in solving sealing challenges in extreme operating environments where performance and longevity are critical.

Unpacking the Core Performance Advantages

The decision to use a PTFE seal is typically driven by one or more demanding application requirements that exceed the capabilities of materials like nitrile or FKM.

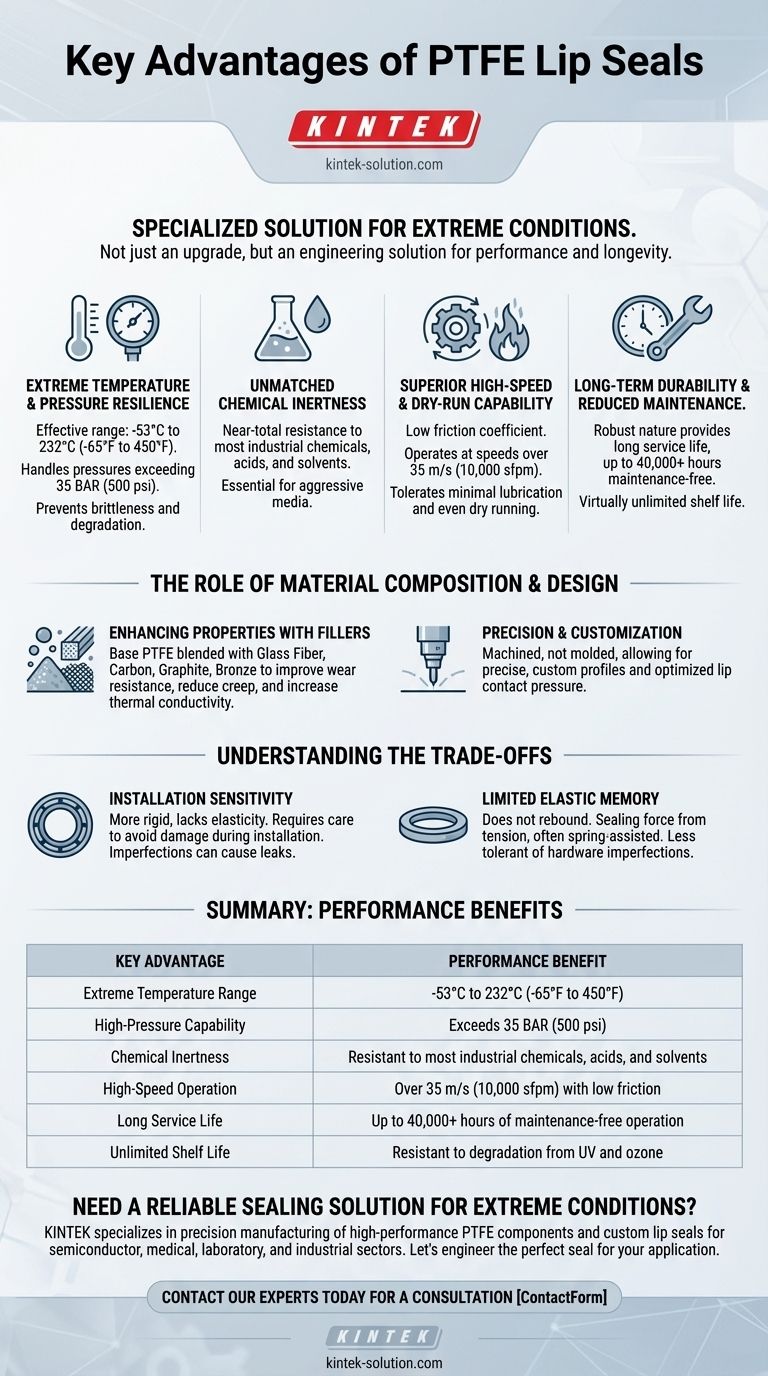

Extreme Temperature and Pressure Resilience

PTFE seals operate effectively across a vast temperature range, typically from -53°C to 232°C (-65°F to 450°F). This stability prevents the material from becoming brittle at low temperatures or degrading at high temperatures.

They are also engineered to handle high pressures, consistently providing a tight seal in environments exceeding 35 BAR (500 psi).

Unmatched Chemical Inertness

One of PTFE's most significant advantages is its near-total chemical inertness. It is unaffected by the vast majority of industrial chemicals, acids, and solvents.

This makes PTFE seals essential for applications in the pharmaceutical, chemical processing, and semiconductor industries where seal integrity in the presence of aggressive media is non-negotiable.

Superior High-Speed and Dry-Run Capability

PTFE has an exceptionally low coefficient of friction. This inherent lubricity minimizes heat generation, even at very high rotational speeds of over 35 m/s (10,000 sfpm).

Unlike elastomeric seals that require lubrication to prevent overheating and rapid wear, PTFE seals can tolerate periods of minimal lubrication and even run dry in certain applications without catastrophic failure.

Long-Term Durability and Reduced Maintenance

The robust nature of PTFE translates directly to a longer, more reliable service life, with some applications reporting over 40,000 hours of maintenance-free operation.

Furthermore, PTFE does not degrade over time from environmental factors like UV or ozone, giving it a virtually unlimited shelf life. This combination of durability and stability reduces long-term operating costs.

The Role of Material Composition and Design

The performance of a PTFE seal isn't just about the base material; it's also about how that material is modified and shaped for a specific purpose.

Enhancing Properties with Fillers

Base PTFE can be blended with various fillers—such as glass fiber, carbon, graphite, or bronze—to enhance specific properties.

Fillers can significantly improve wear resistance, reduce creep (the tendency to deform under load), and increase thermal conductivity to better dissipate heat, further optimizing the seal for its intended application.

Precision and Customization

PTFE seals are typically machined, not molded. This allows for the creation of precise, custom profiles designed to fit specific hardware and meet unique performance criteria.

This ability to tailor the seal geometry is critical for optimizing lip contact pressure and ensuring reliable performance in a specialized application.

Understanding the Trade-offs

While powerful, PTFE seals are a specialized component with unique considerations. Objectivity requires acknowledging their specific operational requirements.

Installation Sensitivity

PTFE is a much more rigid material than rubber. It lacks the elasticity that makes elastomeric seals forgiving during installation.

Care must be taken to avoid scratching the shaft or damaging the seal lip during assembly, as any imperfection can create a leak path. Some designs incorporate an outer elastomer coating to simplify installation.

Limited Elastic Memory

Unlike a rubber seal that rebounds elastically to maintain contact, a PTFE seal has very little "memory." It does not spring back to its original shape once installed.

Sealing force is instead generated by the engineered tension of the seal lip itself, often assisted by a metallic spring energizer. This means they are less tolerant of hardware imperfections like shaft run-out or surface irregularities compared to more compliant elastomeric seals.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its advantages to your primary operational challenge.

- If your primary focus is operating in extreme temperatures or pressures: PTFE seals are the definitive choice where standard elastomers would rapidly degrade and fail.

- If your primary focus is chemical compatibility: PTFE's inertness makes it essential for handling aggressive media in industries like chemical processing or pharmaceuticals.

- If your primary focus is high-speed rotational equipment: The low-friction properties of PTFE prevent destructive heat buildup and allow for surface speeds far beyond the limits of rubber seals.

- If your primary focus is minimizing downtime in critical systems: The exceptional durability and long service life of PTFE seals can significantly lower the total cost of ownership.

Ultimately, choosing a PTFE lip seal is an engineering decision for environments where performance cannot be compromised.

Summary Table:

| Key Advantage | Performance Benefit |

|---|---|

| Extreme Temperature Range | -53°C to 232°C (-65°F to 450°F) |

| High-Pressure Capability | Exceeds 35 BAR (500 psi) |

| Chemical Inertness | Resistant to most industrial chemicals, acids, and solvents |

| High-Speed Operation | Over 35 m/s (10,000 sfpm) with low friction |

| Long Service Life | Up to 40,000+ hours of maintenance-free operation |

| Unlimited Shelf Life | Resistant to degradation from UV and ozone |

Need a reliable sealing solution for extreme conditions?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom lip seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment operates reliably under demanding pressures, temperatures, and chemical exposures, minimizing downtime and total cost of ownership.

We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications. Let's engineer the perfect seal for your application—contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech