In short, adding glass fiber to PTFE fundamentally enhances its mechanical properties. This filler dramatically improves resistance to wear and, most critically, reduces "cold flow" or creep—the tendency of pure PTFE to deform under sustained pressure.

The core reason to choose glass-filled PTFE is to transform the material from a soft, compliant polymer into a more rigid, structurally stable engineering plastic. You gain significant strength and durability for load-bearing applications, but you must accept the trade-offs of increased friction and reduced chemical resistance to certain substances.

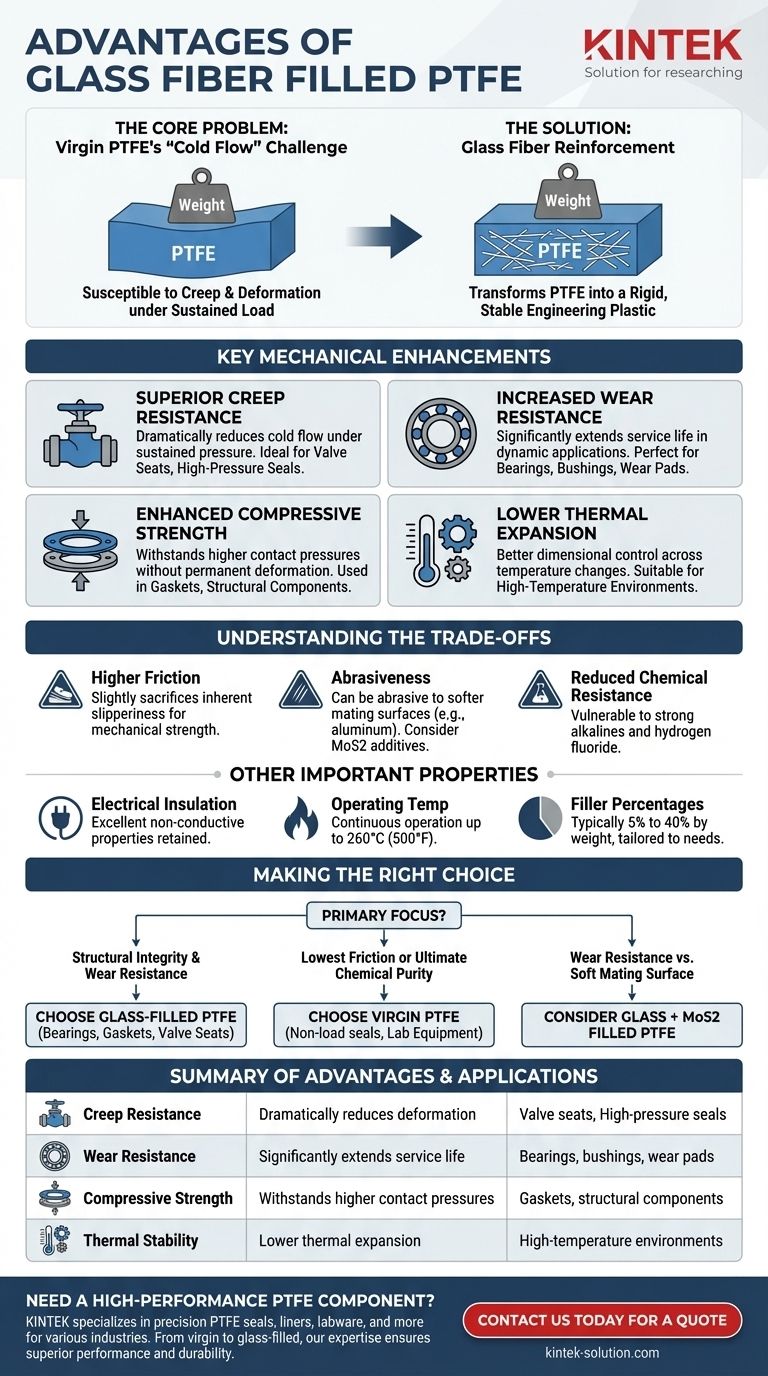

The Core Problem with Virgin PTFE

The Challenge of "Cold Flow"

Virgin (unfilled) PTFE is renowned for its extremely low friction and broad chemical inertness. However, it is a relatively soft material.

Under sustained mechanical load, especially at room temperature, pure PTFE will slowly deform or "creep." This phenomenon, known as cold flow, makes it unsuitable for many structural or high-pressure applications.

The Role of Fillers

Fillers are added to create a composite material that retains many of PTFE's desirable traits while mitigating its weaknesses. The glass fibers act like rebar in concrete, creating an internal support structure.

Key Mechanical Enhancements of Glass-Filled PTFE

Superior Creep (Cold Flow) Resistance

This is the most significant advantage. The rigid glass fibers distributed throughout the PTFE matrix provide a reinforcing skeleton that resists deformation under load.

This makes glass-filled PTFE an excellent choice for components like valve seats, seals, and bearings that are subjected to constant pressure.

Increased Wear Resistance

The addition of glass fibers significantly hardens the PTFE material. This composite is far more resistant to abrasive wear than virgin PTFE, leading to a longer service life in dynamic applications.

Enhanced Hardness and Compressive Strength

Glass-filled PTFE can withstand much higher contact pressures without being permanently deformed. This improved compressive strength is a direct result of the reinforcing filler.

Lower Thermal Expansion

The glass fibers are dimensionally stable with temperature changes. Their presence reduces the overall coefficient of thermal expansion for the composite, meaning parts will hold their shape and tolerances better across a range of operating temperatures.

Understanding the Trade-offs

Higher Coefficient of Friction

While still low, the friction coefficient of glass-filled PTFE is higher than that of virgin PTFE. You are sacrificing some of the material's signature slipperiness in exchange for mechanical strength.

Abrasiveness to Mating Surfaces

The hard glass fibers can be abrasive to softer counter-surfaces, such as aluminum or other plastics. This is a critical design consideration in dynamic sealing or bearing applications.

For applications requiring wear resistance against softer metals, a compound with a secondary lubricant like Molybdenum Disulfide (MoS2) is often used to reduce this abrasive effect.

Reduced Chemical Resistance

While still highly resistant to most chemicals, glass-filled PTFE has specific vulnerabilities. It can be attacked by strong alkalines and hydrogen fluoride, which virgin PTFE would resist.

Other Important Properties

Electrical Insulation

Glass fiber is an excellent insulator. Therefore, adding it to PTFE does not compromise the material's non-conductive properties, making it suitable for electrical applications where mechanical strength is also needed.

Operating Temperature Range

The composite material retains PTFE's outstanding performance at extreme temperatures. It can operate continuously at temperatures up to 260°C (500°F).

Common Filler Percentages

The amount of glass fiber can be tailored to the application's needs, but it typically ranges from 5% to 40% by weight. Higher percentages offer greater mechanical strength but also increase abrasiveness.

Making the Right Choice for Your Application

- If your primary focus is structural integrity and wear resistance: Choose glass-filled PTFE for components like bearings, bushings, gaskets, and valve seats that must resist deformation under load.

- If your primary focus is the lowest possible friction or ultimate chemical purity: Virgin PTFE remains the superior choice for applications like non-load-bearing seals, lab equipment, or medical devices.

- If you need wear resistance against a soft mating surface: Consider a modified compound like glass and MoS2-filled PTFE to gain strength without causing excessive wear on the counter-surface.

Ultimately, filling PTFE with glass fiber is a strategic decision to trade its inherent softness for the robust mechanical properties required in demanding engineering environments.

Summary Table:

| Advantage | Key Benefit | Common Use Case |

|---|---|---|

| Creep Resistance | Dramatically reduces deformation under sustained load | Valve seats, high-pressure seals |

| Wear Resistance | Significantly extends service life in dynamic applications | Bearings, bushings, wear pads |

| Compressive Strength | Withstands higher contact pressures without deforming | Gaskets, structural components |

| Thermal Stability | Lower thermal expansion for better dimensional control | High-temperature environments |

Need a High-Performance PTFE Component?

KINTEK specializes in manufacturing precision PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. Whether your application requires the enhanced mechanical properties of glass-filled PTFE or the ultimate chemical purity of virgin PTFE, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a component engineered for superior performance and durability.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Teflon Parts Manufacturer Conductive Glass Substrate Cleaning Rack

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability