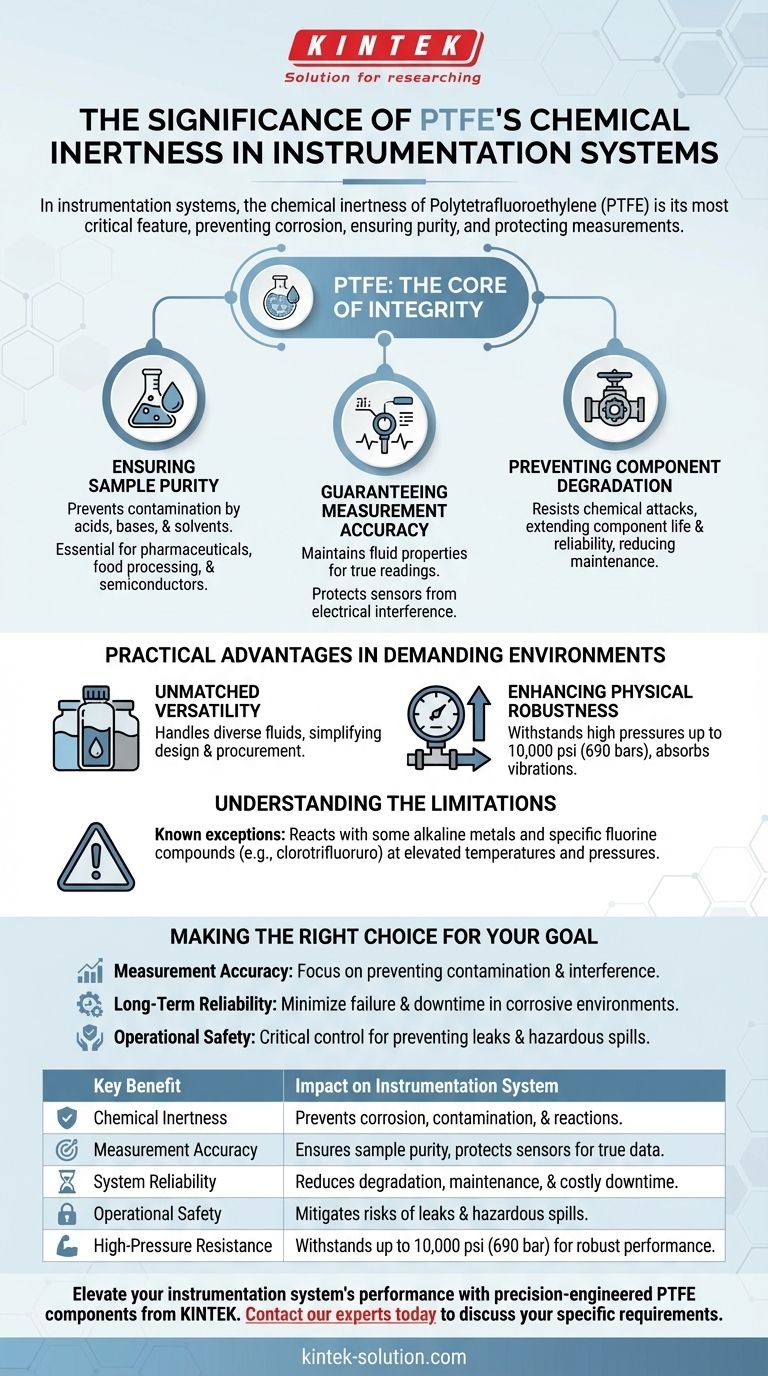

In instrumentation systems, the chemical inertness of Polytetrafluoroethylene (PTFE) is its most critical feature. This property means PTFE does not react with the vast majority of industrial chemicals, which prevents corrosion, ensures the purity of the process media, and protects the integrity of sensitive measurements. It is the foundation of reliability and accuracy in any system that handles corrosive or high-purity fluids.

The significance of PTFE's inertness goes beyond simply preventing rust. In instrumentation, any chemical reaction, no matter how small, is a form of contamination that can corrupt data, damage sensitive components, and compromise system safety.

The Core Principle: Preserving System Integrity

The fundamental job of an instrumentation system is to measure and control a process with high fidelity. The materials used must be passive observers, not active participants. PTFE's chemical inertness makes it an ideal passive material.

Ensuring Sample Purity

Any component that touches the process fluid—from tubing to valve seats to sensor housings—must not alter its chemical composition.

Because PTFE is inert to nearly all acids, bases, and solvents, it guarantees that the sample flowing through the system remains uncontaminated. This is essential for applications in pharmaceuticals, food processing, and semiconductor manufacturing where even trace impurities can ruin a batch.

Guaranteeing Measurement Accuracy

Inaccurate measurements often stem from a compromised sample or a failing sensor.

PTFE prevents chemical reactions that could alter the properties of the fluid being measured, ensuring sensors provide a true reading. Furthermore, PTFE's excellent electrical insulation properties protect sensitive electronic sensors from electrical interference, preserving signal purity alongside chemical purity.

Preventing Component Degradation

Instrumentation systems must perform reliably for long periods, often in harsh conditions.

Chemical attacks are a primary cause of material failure, leading to leaks, costly downtime, and potential safety hazards. PTFE's resistance to chemical degradation means components last longer, require less maintenance, and provide a much higher degree of operational safety.

Practical Advantages in Demanding Environments

While inertness is the key chemical property, PTFE's physical characteristics make it a robust solution for real-world instrumentation challenges.

Unmatched Versatility

The ability to handle nearly any liquid or gas means PTFE can be specified for a wide array of applications.

This simplifies the design and procurement process, as engineers can rely on a single, proven material for diverse chemical services without needing to stock multiple polymer types.

Enhancing Physical Robustness

Instrumentation systems are not just chemical conduits; they are physical structures.

PTFE is capable of withstanding high pressures up to 10,000 psi (690 bars), making it suitable for demanding oil and gas applications. It also absorbs vibrations, cushioning pipes and components from mechanical shock, which preserves the system's structural integrity over time.

Understanding the Limitations

While exceptionally non-reactive, PTFE is not completely immune under all conceivable conditions. Understanding its boundaries is key to proper application.

The Chemical Exceptions

PTFE's inertness has a few known exceptions. It can react with some alkaline metals and specific fluorine compounds, such as clorotrifluoruro, particularly at elevated temperatures and pressures.

For the vast majority of industrial applications, these exceptions are not a concern. However, they must be considered when designing systems for highly specialized or extreme chemical processes.

Making the Right Choice for Your Goal

Selecting the right material is about matching its properties to your most critical operational need.

- If your primary focus is measurement accuracy: PTFE's inertness is non-negotiable, as it prevents sample contamination and signal interference that would otherwise invalidate your data.

- If your primary focus is long-term reliability: Its profound resistance to chemical attack minimizes component failure, drastically reducing downtime and maintenance costs in corrosive environments.

- If your primary focus is operational safety: Using a non-reactive material like PTFE is a critical control for preventing leaks and hazardous spills when handling aggressive or toxic media.

Ultimately, choosing PTFE is a decision to prioritize the integrity and dependability of your entire instrumentation system.

Summary Table:

| Key Benefit | Impact on Instrumentation System |

|---|---|

| Chemical Inertness | Prevents corrosion, contamination, and reactions with acids, bases, and solvents. |

| Measurement Accuracy | Ensures sample purity and protects sensors for true, reliable data. |

| System Reliability | Reduces component degradation, maintenance, and costly downtime. |

| Operational Safety | Mitigates risks of leaks and hazardous spills from material failure. |

| High-Pressure Resistance | Withstands pressures up to 10,000 psi (690 bar) for robust performance. |

Elevate your instrumentation system's performance with precision-engineered PTFE components from KINTEK.

Does your application in the semiconductor, medical, laboratory, or industrial sector demand uncompromising chemical resistance and reliability? Our expertise in custom PTFE fabrication—from prototypes to high-volume orders—ensures your components are built to preserve sample purity, guarantee measurement accuracy, and enhance operational safety.

Contact our experts today to discuss your specific requirements and discover how KINTEK's PTFE solutions can protect your critical processes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability