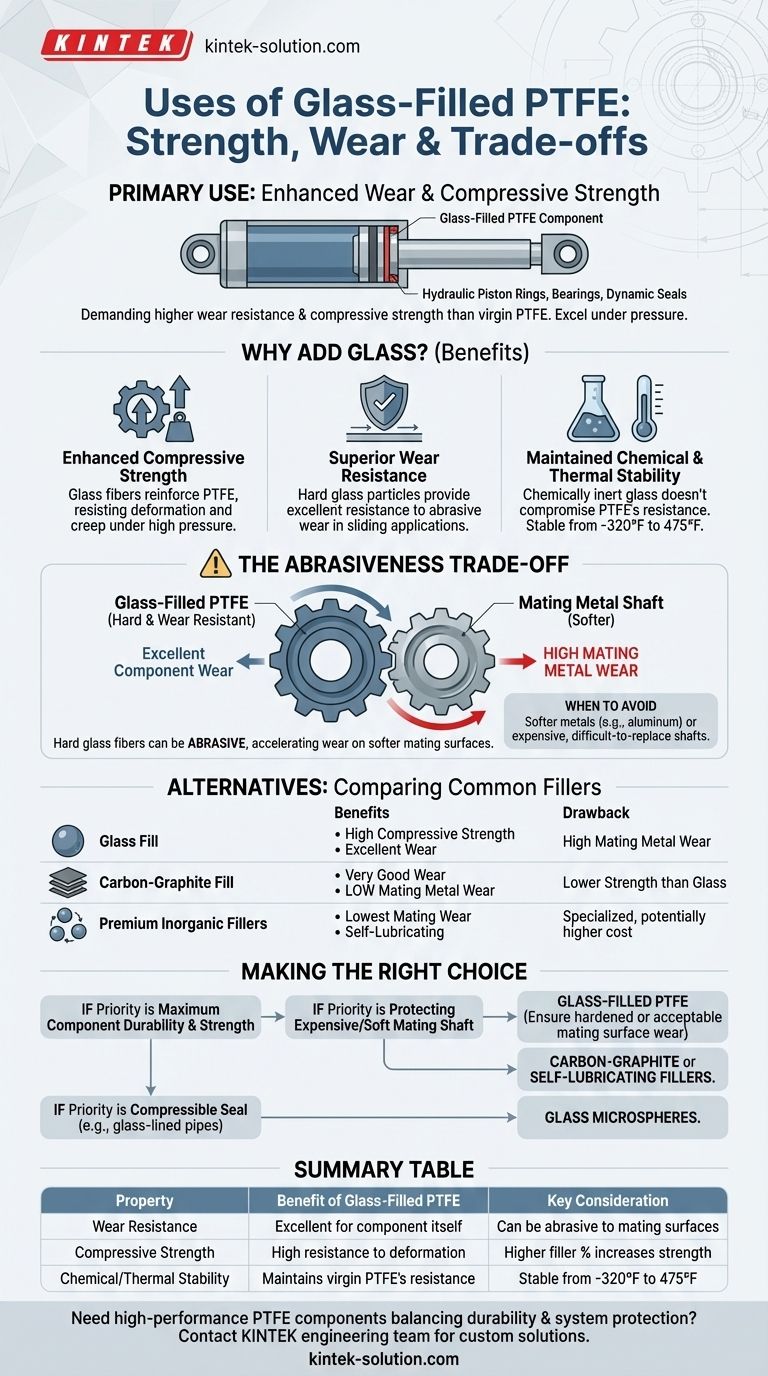

The primary use of glass-filled Polytetrafluoroethylene (PTFE) is in applications demanding significantly higher wear resistance and compressive strength than virgin PTFE can provide. It excels in components like hydraulic piston rings, bearings, and dynamic seals where durability under pressure is critical. While it retains the excellent chemical resistance of PTFE, its abrasive nature must be carefully considered.

The core decision to use glass-filled PTFE hinges on a single trade-off: you gain exceptional strength and wear resistance for the component itself, but at the cost of increased wear on the mating surface, such as a metal shaft.

Why Add Glass to PTFE?

Virgin PTFE is known for its incredible chemical resistance and low friction, but it is mechanically soft and prone to deforming under load (a phenomenon known as "creep"). Adding glass fibers directly addresses these mechanical weaknesses.

Enhanced Compressive Strength

Glass fibers act as a reinforcing agent within the PTFE matrix. This reinforcement drastically improves the material's ability to resist deformation and creep when subjected to high pressure.

Higher percentages of glass filler will generally result in higher compressive strength, making it suitable for high-load bearing applications.

Superior Wear Resistance

The hardness of the glass particles provides excellent resistance to abrasive wear. This makes the material last much longer in dynamic applications where parts are sliding against one another.

This property is why it is a common choice for components like piston rings, which constantly move within a cylinder.

Maintained Chemical & Thermal Stability

Glass is chemically inert, so its addition does not compromise PTFE's renowned resistance to a wide range of chemicals.

Glass-filled PTFE also maintains a very wide operational temperature range (from -320°F to 475°F), making it stable in extreme environments.

Understanding the Trade-offs: The Abrasiveness Factor

The most critical factor to consider when specifying glass-filled PTFE is its effect on other components in the system.

High Mating Metal Wear

The same hard glass fibers that provide excellent wear resistance for the PTFE part can be abrasive to the surfaces they contact.

This means a glass-filled PTFE bearing or seal can cause accelerated wear on a softer metal shaft or bore over time. This is its single biggest drawback.

When to Avoid Glass Fill

You should be cautious about using glass-filled PTFE against softer metals (like aluminum) or in systems where the mating shaft or bore is very expensive or difficult to replace.

The cost of replacing a worn shaft often far exceeds the cost of the bearing or seal.

How Glass Compares to Other Common Fillers

The limitations of glass filler have led to the development of other PTFE blends designed for different performance characteristics.

Carbon-Graphite Fill

This filler also provides very good wear resistance but is known for having low mating metal wear. It is a superior choice when preserving the condition of the shaft is a primary concern, especially in humid or fluid applications.

Premium Inorganic Fillers

Certain proprietary inorganic fillers are engineered to be self-lubricating. These blends offer one of the lowest metal-mating wear characteristics available, making them ideal for high-speed rotary applications where shaft preservation is paramount.

Making the Right Choice for Your Application

Selecting the correct filler is about understanding the requirements of the entire mechanical system, not just the single component.

- If your primary focus is maximum durability and compressive strength for the component: Glass-filled PTFE is often the most effective and economical choice, provided the mating surface is hardened or its wear is acceptable.

- If your primary focus is protecting an expensive or soft mating shaft: Carbon-graphite or other self-lubricating inorganic fillers are a much safer and more appropriate specification.

- If your primary focus is a compressible seal for a specific use like glass-lined pipes: Glass microspheres offer unique properties tailored for this niche application.

Ultimately, choosing the right filled PTFE requires you to balance the desired performance of the part with its effect on the entire assembly.

Summary Table:

| Property | Benefit of Glass-Filled PTFE | Key Consideration |

|---|---|---|

| Wear Resistance | Excellent for the component itself | Can be abrasive to mating surfaces |

| Compressive Strength | High resistance to deformation/creep | Higher filler % increases strength |

| Chemical/Thermal Stability | Maintains virgin PTFE's broad resistance | Stable from -320°F to 475°F |

Need high-performance PTFE components that balance durability with system-wide protection?

At KINTEK, we specialize in precision manufacturing of PTFE seals, bearings, liners, and custom labware for the semiconductor, medical, and industrial sectors. Our experts can help you select the ideal filler material—whether glass, carbon-graphite, or a premium self-lubricating blend—to ensure your component performs reliably without compromising your mating surfaces.

We provide custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact specifications for strength, wear resistance, and chemical compatibility.

Contact our engineering team today for a consultation on your next PTFE project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components