At its core, Polytetrafluoroethylene (PTFE) is the preferred material for high-speed rotary shaft seals due to its exceptionally low coefficient of friction and superior thermal stability. In high-speed applications, traditional elastomeric seals generate immense frictional heat, causing them to harden, crack, and fail. PTFE's unique properties allow it to operate under these demanding conditions with minimal heat buildup and wear, ensuring a longer and more reliable service life.

The fundamental problem in high-speed sealing is not the motion itself, but the destructive heat generated by friction. While traditional seals fight friction and lose, PTFE avoids the fight altogether with its inherent low-friction, self-lubricating nature, making it the superior choice for high-velocity applications.

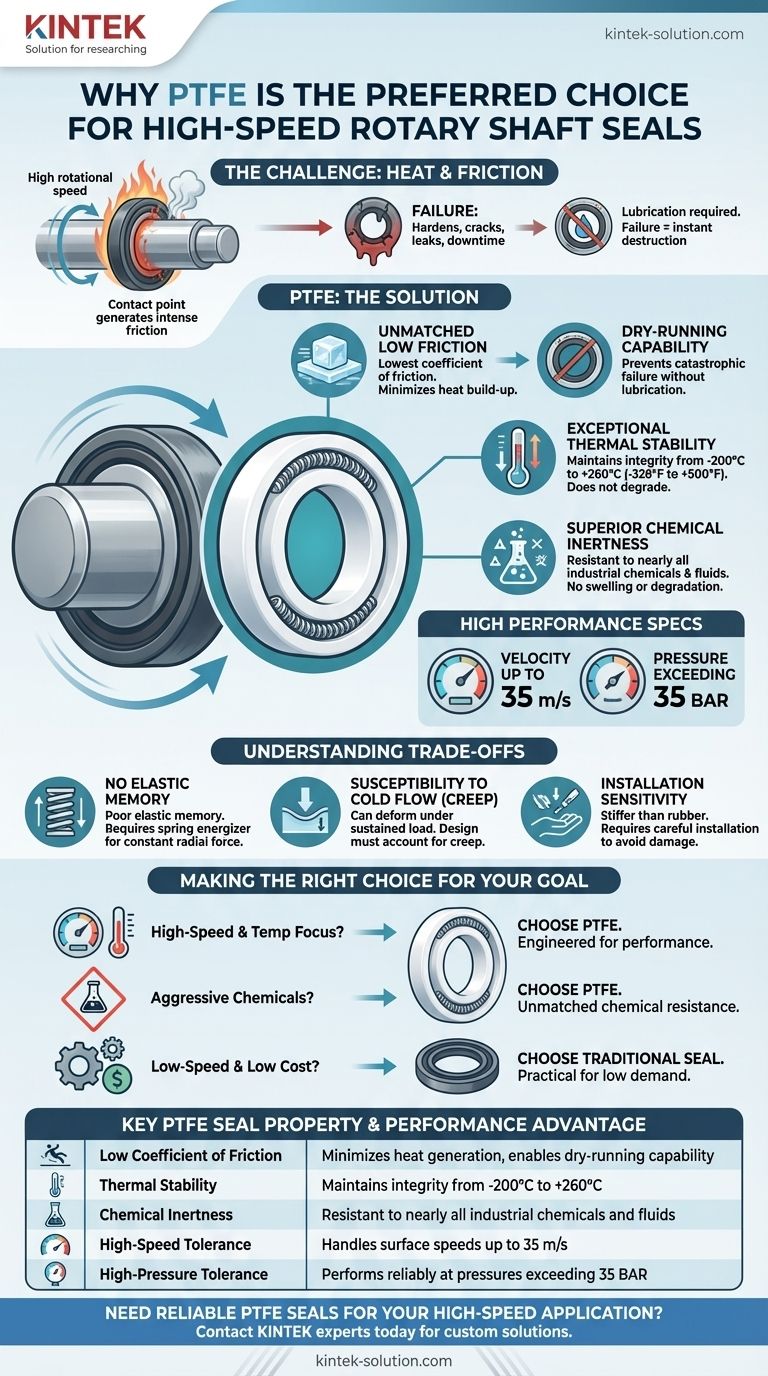

The Fundamental Challenge: Heat and Friction in Rotary Sealing

At high rotational speeds, the contact point between a seal lip and a shaft becomes a major source of friction. This friction inevitably generates heat.

How Heat Destroys Traditional Seals

Standard elastomeric seals, like those made from nitrile or Viton®, are vulnerable to high temperatures. Excessive heat causes them to lose their flexibility, become brittle, and ultimately fail, leading to leaks and costly equipment downtime.

The Lubrication Dependency

Most traditional seals require a constant film of lubrication to reduce friction and dissipate heat. If this lubrication fails or is insufficient—a condition known as dry-running—the seal will be destroyed in a matter of moments.

Key PTFE Properties for High-Speed Performance

PTFE overcomes the core challenges of heat and friction through a unique combination of material properties. It is not just one feature, but the synergy of several, that makes it so effective.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slippery" characteristic drastically reduces the heat generated against a rotating shaft.

This property also allows for dry-running capability, meaning PTFE seals can function effectively for periods without lubrication, a critical advantage that prevents catastrophic failure.

Exceptional Thermal Stability

PTFE maintains its integrity across an extremely wide temperature range, typically from -328°F to +500°F (-200°C to +260°C).

Even when some frictional heat is generated, the material does not degrade, harden, or lose its sealing ability, unlike its elastomeric counterparts.

Superior Chemical Inertness

PTFE is non-reactive and resistant to nearly all industrial chemicals, fluids, and lubricants. This ensures the seal will not swell, soften, or degrade when exposed to aggressive media, making it highly versatile.

High Pressure and Velocity Tolerance

Engineered PTFE seals are designed to perform under extreme dynamic conditions. They can reliably handle surface speeds up to 35 m/s and pressures exceeding 35 BAR, specifications where traditional seals would be unusable.

Understanding the Trade-offs of PTFE Seals

No material is a universal solution. While PTFE excels in high-performance scenarios, its properties introduce specific design and handling considerations. Acknowledging these trade-offs is crucial for successful implementation.

Lack of Elastic Memory

Unlike rubber, PTFE is not a true elastomer and has very poor elastic memory. It will not "spring back" to its original shape after being deformed.

Because of this, most PTFE seal designs incorporate a metallic spring or energizer to provide the constant radial force needed to maintain a tight seal against the shaft.

Susceptibility to Cold Flow (Creep)

Under a sustained load, PTFE can slowly deform over time in a process known as "creep" or "cold flow." Proper seal design accounts for this, but it is a factor that can impact long-term sealing performance if not managed correctly.

Installation Sensitivity

The relative stiffness of PTFE compared to rubber means that installation requires more care. The seal lip can be nicked, scratched, or permanently deformed if not installed using the proper tools and procedures.

Making the Right Choice for Your Goal

Selecting the correct sealing material requires a clear understanding of your application's primary demands.

- If your primary focus is high-speed and high-temperature performance: PTFE is the definitive choice, as it's specifically engineered to handle the heat and friction that cause other seals to fail.

- If your application involves aggressive chemicals or lubricants: PTFE's chemical inertness provides unmatched reliability and prevents material degradation that would compromise other materials.

- If your primary constraints are low cost and simple installation for a low-speed application: A traditional elastomeric (rubber) seal may be a more practical and cost-effective solution.

Ultimately, understanding these core principles empowers you to select a sealing solution based on performance requirements rather than just material preference.

Summary Table:

| Key PTFE Seal Property | Performance Advantage |

|---|---|

| Low Coefficient of Friction | Minimizes heat generation, enables dry-running capability |

| Thermal Stability | Maintains integrity from -200°C to +260°C |

| Chemical Inertness | Resistant to nearly all industrial chemicals and fluids |

| High-Speed Tolerance | Handles surface speeds up to 35 m/s |

| High-Pressure Tolerance | Performs reliably at pressures exceeding 35 BAR |

Need reliable PTFE seals for your high-speed application?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including seals, liners, and labware. Our expertise ensures your equipment operates reliably under the most demanding conditions—whether in semiconductor, medical, laboratory, or industrial settings.

We offer custom fabrication from prototypes to high-volume orders, tailoring solutions to your exact specifications. Don't let seal failure cause costly downtime.

Contact our experts today to discuss your specific requirements and discover how our PTFE solutions can enhance your operational efficiency and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the advantages of using PTFE combined with glass fiber aggregates? Achieve Superior Strength & Durability

- What is the role of factory run tests for PTFE Lip Seals? De-Risk Your Critical Sealing Applications

- How is MoS2 (Moly) typically combined in PTFE applications? Synergistic Fillers for Low Friction

- What makes PTFE bushes suitable for corrosive environments? Unmatched Chemical Resistance and Reliability

- What does the leakage rate indicate about PTFE gaskets? Understanding the Sealing Performance Trade-off

- What may be required to help PTFE seals dissipate heat more quickly? Use Conductive Fillers for High-Temp Reliability

- What are the key considerations for selecting PTFE material for high performance butterfly valves? Ensure Long-Term Reliability

- What is PTFE and why is it desirable for CNC machining? Unlock Superior Performance for Demanding Applications