At its core, the suitability of Polytetrafluoroethylene (PTFE) bushes for corrosive environments stems from their extreme chemical inertness. This property is a direct result of the powerful carbon-fluorine bonds that make up its molecular structure, rendering it non-reactive to nearly all acids, bases, and industrial solvents. This ensures the bushing maintains its structural integrity and performance where most other materials would degrade and fail.

The true advantage of PTFE in corrosive applications is not just its chemical resistance, but the powerful combination of this immunity with its self-lubricating nature and wide temperature tolerance. This trio eliminates multiple common failure points—material degradation, lubricant breakdown, and thermal instability—at once.

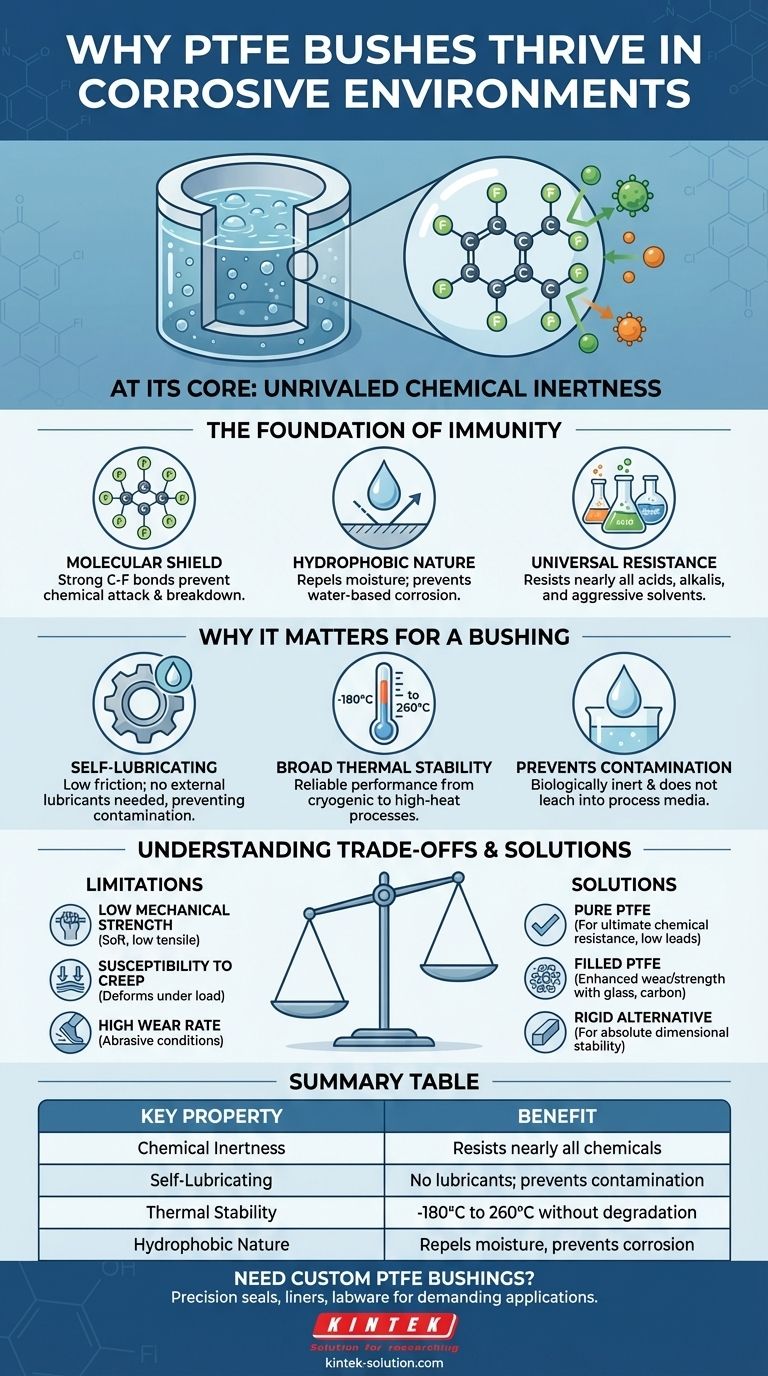

The Foundation of PTFE's Chemical Immunity

PTFE's reputation is built on its ability to survive in environments that are hostile to almost every other polymer and metal. This resilience is not a single feature but a result of its fundamental chemical makeup.

Unrivaled Chemical Inertness

PTFE is resistant to a vast spectrum of substances, including highly concentrated acids, alkalis, and aggressive organic solvents. This makes it a default choice for equipment used in chemical processing, pharmaceuticals, and manufacturing.

Unlike other materials that may only resist a specific class of chemicals, PTFE's resistance is nearly universal.

The Impact of Molecular Structure

The exceptional stability of PTFE comes from the strength of its carbon-fluorine bonds. These bonds are incredibly strong and tightly shield the carbon backbone of the polymer molecule.

This molecular shield prevents chemical agents from attacking and breaking down the polymer chain, which is the primary mechanism of chemical corrosion in plastics.

Hydrophobic and Non-Reactive Nature

PTFE is also hydrophobic, meaning it repels water and does not absorb moisture. This prevents water-based corrosive agents from penetrating the material.

Furthermore, it is biologically inert, meaning it will not react with or support biological growth, a critical feature for food-grade and medical applications.

Why This Matters Specifically for a Bushing

A bushing is a functional component that must do more than just survive; it must perform. PTFE’s properties align perfectly with the demands of a bearing or bushing operating within a corrosive zone.

Self-Lubricating Performance

PTFE has one of the lowest coefficients of friction of any solid material, giving it a self-lubricating, non-stick surface.

This is a critical advantage in corrosive environments where traditional greases or oils would either be washed away, contaminated, or react with the surrounding chemicals, leading to catastrophic failure.

Broad Thermal Stability

Chemical processes often involve extreme temperatures. PTFE maintains its key properties over a vast temperature range, typically from -180°C (-292°F) to 260°C (500°F).

This stability ensures the bushing performs reliably whether the application involves cryogenic fluids or high-temperature processing.

Preventing Media Contamination

Because PTFE is inert and requires no external lubricants, it does not leach substances into the process media.

This purity is essential in industries like food and beverage, pharmaceuticals, and electronics, where even trace amounts of contamination are unacceptable.

Understanding the Trade-offs and Limitations

No material is perfect. While PTFE's chemical and thermal properties are exceptional, its mechanical properties present clear trade-offs that are critical to understand for successful application design.

Relatively Low Mechanical Strength

Pure PTFE is a relatively soft material with low tensile strength and stiffness compared to engineering plastics like PEEK or even nylon. It is not suitable for high-load structural applications.

Susceptibility to Creep

Under a constant compressive load, PTFE can be subject to creep, or cold flow, where the material slowly deforms over time. This can lead to a loss of tolerance and must be accounted for in the design of the assembly.

High Rate of Wear

While it has a low-friction surface, the softness of pure PTFE means it can wear down quickly in applications with abrasive particles or high point loads. To combat this, PTFE is often blended with fillers like glass, carbon, or bronze to enhance its mechanical strength and wear resistance.

Making the Right Choice for Your Application

Selecting the right material requires balancing the demands of the environment with the mechanical needs of the component.

- If your primary focus is ultimate chemical resistance with low loads: Pure PTFE is an ideal choice, offering unmatched protection against nearly all corrosive media.

- If your application involves high pressure or abrasive particles: Consider a filled-PTFE composite, which significantly improves wear resistance and load-bearing capability.

- If your environment requires absolute dimensional stability under constant load: You must carefully evaluate PTFE's potential for creep and may need to consider a more rigid material.

Ultimately, choosing PTFE for its chemical resistance is a sound engineering decision, provided you design around its mechanical limitations.

Summary Table:

| Key Property | Benefit for Corrosive Environments |

|---|---|

| Chemical Inertness | Resists nearly all acids, bases, and solvents |

| Self-Lubricating | No external lubricants needed; prevents contamination |

| Thermal Stability | Performs from -180°C to 260°C without degradation |

| Hydrophobic Nature | Repels moisture; prevents water-based corrosion |

Need a PTFE bushing that withstands your toughest corrosive challenges? At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for semiconductor, medical, laboratory, and industrial applications. Our custom fabrication services, from prototypes to high-volume orders, ensure your bushings are engineered for both chemical resistance and mechanical performance. Contact us today to discuss your specific requirements and let our expertise enhance your application's reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications