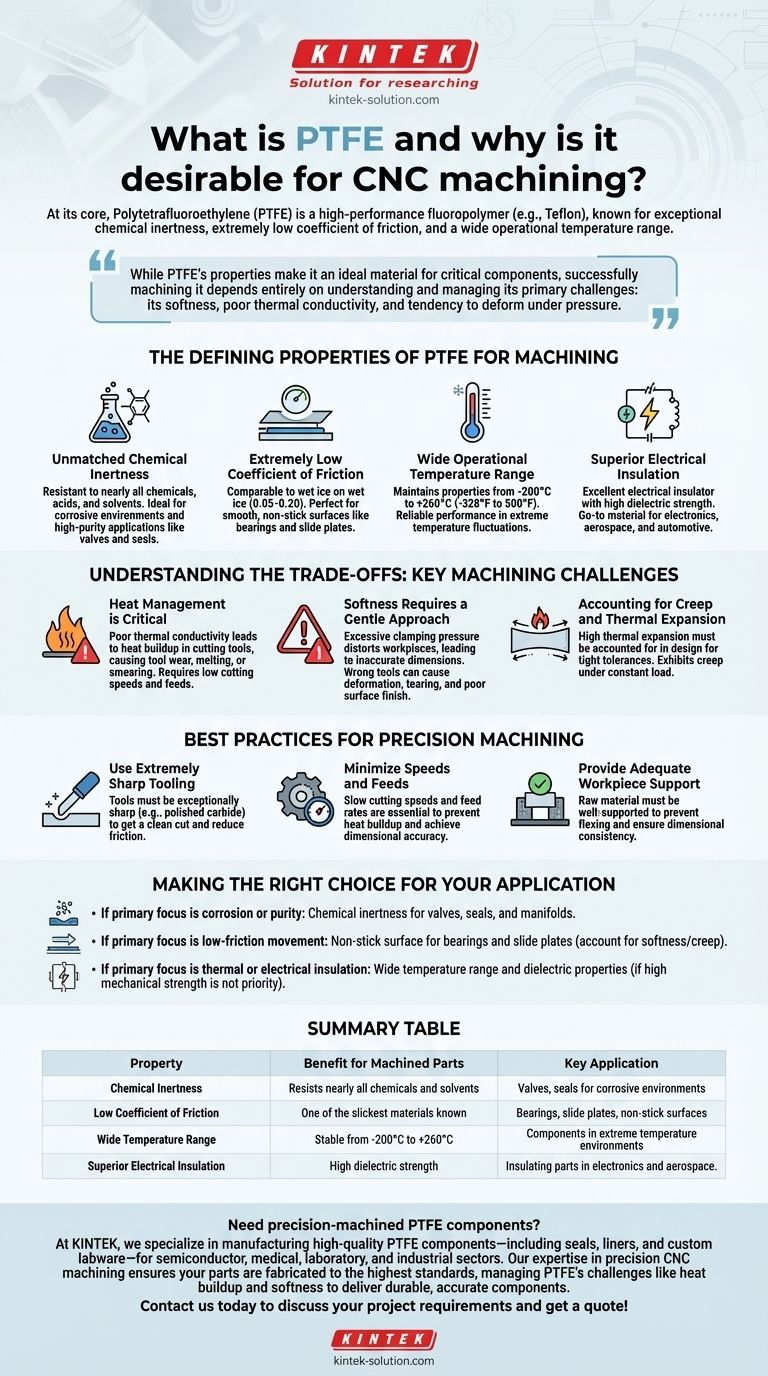

At its core, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer, known commercially by brand names like Teflon. It is highly desirable for CNC machining because it combines exceptional chemical inertness, an extremely low coefficient of friction, and a wide operational temperature range, making it a uniquely versatile material for demanding applications.

While PTFE's properties make it an ideal material for critical components, successfully machining it depends entirely on understanding and managing its primary challenges: its softness, poor thermal conductivity, and tendency to deform under pressure.

The Defining Properties of PTFE for Machining

The reason PTFE is so frequently specified for machined parts is its unique combination of characteristics that are difficult to find in a single material.

Unmatched Chemical Inertness

PTFE is resistant to nearly all chemicals, acids, and solvents. This makes it an ideal choice for components used in corrosive environments or for high-purity applications.

This is why you often find machined PTFE in parts like valves and seals for sanitary or chemical etching processes.

Extremely Low Coefficient of Friction

With a friction coefficient comparable to wet ice on wet ice (0.05–0.20), PTFE is one of the "slickest" substances known. This makes it perfect for applications requiring smooth, non-stick surfaces like bearings or slide plates.

Wide Operational Temperature Range

PTFE maintains its properties across an impressive temperature spectrum, typically from -200°C to +260°C (-328°F to 500°F). This stability allows it to perform reliably in environments with extreme temperature fluctuations.

Superior Electrical Insulation

As an excellent electrical insulator with high dielectric strength, PTFE is a go-to material for machined components in the electronics, aerospace, and automotive industries.

Understanding the Trade-offs: Key Machining Challenges

PTFE's unique properties also introduce specific challenges during the CNC machining process. Ignoring these will result in poor-quality parts and dimensional inaccuracies.

Heat Management is Critical

The material has poor thermal conductivity, meaning it doesn't dissipate heat well. During machining, heat builds up in the cutting tool rather than the workpiece, which can lead to tool wear and melting or smearing of the material.

This necessitates low cutting speeds and feeds to prevent excessive heat generation.

Softness Requires a Gentle Approach

PTFE is a soft and flexible material. Excessive clamping pressure during setup will easily distort the workpiece, leading to inaccurate final dimensions.

This softness also means the material can deform or tear rather than cut cleanly if the wrong tools are used. This can cause "tool chatter" and a poor surface finish.

Accounting for Creep and Thermal Expansion

The material has a high rate of thermal expansion, which must be accounted for in any design requiring tight tolerances. It also exhibits creep, a tendency to slowly deform over time when under a constant load.

Because of PTFE's natural resilience, parts can often conform to their working dimensions, but this must be a conscious design consideration.

Best Practices for Precision Machining

To overcome its challenges, machining PTFE requires a specific approach that differs from working with metals or harder plastics.

Use Extremely Sharp Tooling

To get a clean cut instead of pushing or smearing the material, tools must be exceptionally sharp. Polished carbide tools are often recommended to further reduce friction and material buildup on the cutting edge.

Minimize Speeds and Feeds

Slow cutting speeds and feed rates are essential to prevent heat buildup. This is the most important factor in achieving dimensional accuracy and a good surface finish. Using coolants can also help manage temperature for tighter tolerance work.

Provide Adequate Workpiece Support

Due to its flexibility, the raw material must be well-supported during the machining process. This prevents the part from flexing away from the cutting tool, which would cause dimensional inconsistencies.

Making the Right Choice for Your Application

Choosing PTFE is a matter of matching its unique strengths to the primary goal of your component.

- If your primary focus is corrosion or purity: PTFE's chemical inertness is its greatest asset for parts like valves, seals, and manifolds in chemical or sanitary systems.

- If your primary focus is low-friction movement: Its non-stick surface is ideal for bearings and slide plates, but the design must account for its softness and potential for creep under load.

- If your primary focus is thermal or electrical insulation: Its performance across a wide temperature range and excellent dielectric properties make it a top choice, provided high mechanical strength is not the priority.

Ultimately, PTFE is an exceptional material whose unparalleled properties justify the specialized knowledge required to machine it correctly.

Summary Table:

| Property | Benefit for Machined Parts | Key Application |

|---|---|---|

| Chemical Inertness | Resists nearly all chemicals and solvents | Valves, seals for corrosive environments |

| Low Coefficient of Friction | One of the slickest materials known | Bearings, slide plates, non-stick surfaces |

| Wide Temperature Range | Stable from -200°C to +260°C | Components in extreme temperature environments |

| Superior Electrical Insulation | High dielectric strength | Insulating parts in electronics and aerospace |

Need precision-machined PTFE components that leverage these unique properties?

At KINTEK, we specialize in manufacturing high-quality PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision CNC machining ensures your parts are fabricated to the highest standards, managing PTFE's challenges like heat buildup and softness to deliver durable, accurate components.

We offer custom fabrication from prototypes to high-volume orders, ensuring your application benefits from PTFE's full potential. Contact us today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How should Teflon parts be handled during machining to prevent deformation? Master the 3-Step Strategy

- How do PTFE slide bearings ensure consistent performance? Discover the Science of Reliable, Maintenance-Free Motion

- How does the large expansion coefficient of PTFE material affect processing? Master Dimensional Stability

- What are the benefits of Modified PTFE with Carbon-Graphite Fill? Achieve Balanced Sealing Performance

- What are the two production methods for PTFE sliding bearing pads? A Guide to Manufacturing Choices

- What is the purpose of the built-in spring in PTFE shaft seals? To Ensure a Reliable, Long-Lasting Seal

- What pressure ranges are common in oil and gas applications, and how do PTFE seals perform? Reliable Sealing from 1,500 to 25,000 PSI

- How can AI and machine learning improve CNC machining processes for PTFE parts? Boost Precision & Reduce Waste