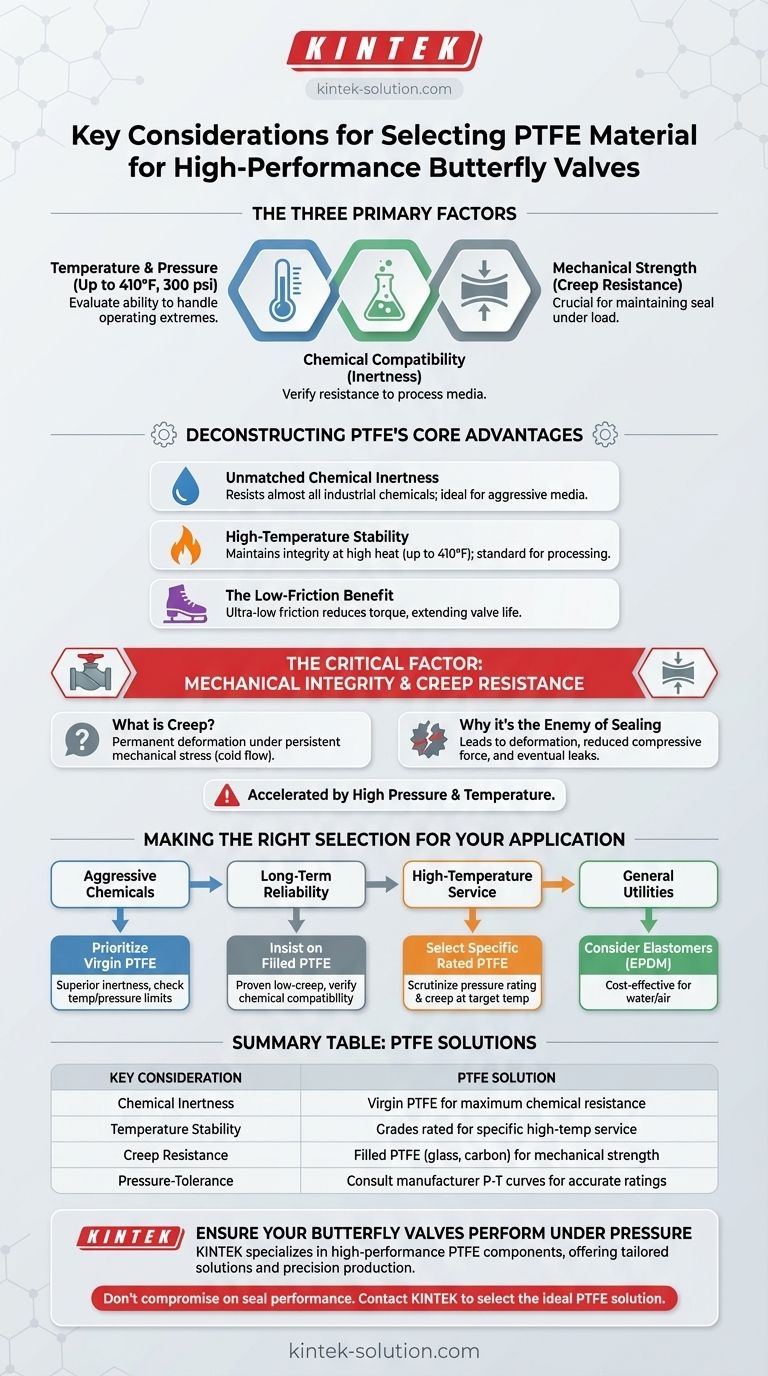

In selecting a PTFE material for a high-performance butterfly valve, you must evaluate three primary factors. These are the material's ability to handle the application's temperature and pressure, its compatibility with the process media (chemical inertness), and its mechanical strength, specifically its resistance to deformation under load (creep resistance). Most standard PTFE seats are rated for service below 410°F (210°C) and 300 psi.

While PTFE is known for its chemical and temperature resistance, the single most critical factor for long-term valve performance is its mechanical integrity. The ability to resist creep and maintain a consistent seal under pressure and temperature is what separates a reliable valve from one that will fail prematurely.

Deconstructing PTFE's Core Advantages

To make an informed decision, it's essential to understand not just what PTFE is, but why its specific properties are uniquely suited for demanding valve applications.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals. This makes it the default choice for services involving aggressive or corrosive media, such as acids, solvents, or caustics, where other elastomers like EPDM would quickly degrade.

Its inert nature also makes it ideal for high-purity applications in pharmaceuticals or food and beverage, as it will not contaminate the process media.

High-Temperature Stability

PTFE maintains its structural integrity and performance characteristics at high temperatures, making it a standard for the petrochemical and chemical processing industries.

While materials like EPDM are excellent for water or steam, they typically cannot handle the extreme heat where PTFE excels, ensuring the valve seal remains effective and does not break down.

The Low-Friction Benefit

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is a significant operational advantage.

A low-friction seat reduces the torque required to open and close the valve. This allows for smaller, less expensive actuators and reduces wear and stress on the valve stem and seat itself, extending the valve's operational life.

The Critical Factor: Mechanical Integrity Under Load

A material's chemical and thermal ratings are meaningless if it cannot maintain a physical seal. For PTFE seats, this comes down to its ability to resist deformation over time.

Understanding Creep Resistance

Creep (also known as "cold flow") is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress. For a valve seat, this stress comes from the disc compressing it to create a seal.

Why Creep Is the Enemy of Sealing

If a PTFE seat has poor creep resistance, it will slowly flow or deform out of its original shape. This deformation reduces the compressive force between the seat and the disc, eventually leading to leaks.

This is one of the most common failure modes for soft-seated valves in high-performance service. The valve may pass a seat test upon installation but begin leaking months later as the seat material deforms.

The Impact of Pressure and Temperature

Creep is significantly accelerated by both high pressure and high temperature. A material that is stable at ambient conditions may deform rapidly when subjected to the combined stress of the application's operating conditions. Therefore, selecting a PTFE grade specifically tested for creep resistance at your target temperature and pressure is paramount.

Understanding the Trade-offs and Limitations

While PTFE is a superior material, it is not a universal solution. Acknowledging its limitations is key to preventing misapplication and failure.

Not All PTFE Is Created Equal

"PTFE" is a family of materials. Virgin PTFE offers the best chemical resistance and lowest friction, but it has the highest tendency to creep.

To combat this, manufacturers offer filled PTFE grades. By adding fillers like glass, carbon, or graphite, they dramatically improve creep resistance and mechanical strength. However, these fillers can sometimes reduce the material's overall chemical compatibility, requiring careful verification against your process media.

The Pressure/Temperature Boundary

The stated limits of 410°F and 300 psi are not independent. A material's pressure-holding capability decreases as temperature increases. Always consult the valve manufacturer's pressure-temperature (P-T) curve to ensure the PTFE seat is suitable for your specific operating point, not just the maximums.

Forgiveness During Installation

Compared to more flexible elastomers, PTFE is a relatively rigid material. It is less forgiving of pipe misalignment or improper flange bolt torque during installation. Over-tightening can crush the seat, creating a failure point before the valve even enters service.

Making the Right Selection for Your Application

Use your primary operational goal to guide your material specification.

- If your primary focus is handling aggressive chemicals: Prioritize virgin PTFE for its superior chemical inertness, but verify that your operating conditions are well within its more limited pressure and temperature range.

- If your primary focus is long-term seal reliability in demanding service: Insist on a filled PTFE grade with proven low-creep characteristics and confirm its chemical compatibility with your media.

- If your primary focus is high-temperature service (below 410°F): Select a PTFE grade specifically rated for that temperature and scrutinize its pressure rating and creep resistance at that specific heat level.

- If your primary focus is general utilities like water or air: Consider more cost-effective elastomers like EPDM, as the premium performance and cost of PTFE are likely unnecessary.

Ultimately, selecting the right PTFE seat is about ensuring the material's mechanical strength is sufficient to maintain a seal under the unique chemical and thermal stresses of your application.

Summary Table:

| Key Consideration | Why It Matters | PTFE Solution |

|---|---|---|

| Chemical Inertness | Resists aggressive/corrosive media | Virgin PTFE for maximum chemical resistance |

| Temperature Stability | Maintains seal integrity up to 410°F (210°C) | Grades rated for specific high-temperature service |

| Creep Resistance | Prevents deformation and leaks under load | Filled PTFE (glass, carbon) for mechanical strength |

| Pressure-Tolerance | Holds seal under operational stress (up to 300 psi) | Consult manufacturer P-T curves for accurate ratings |

Ensure Your Butterfly Valves Perform Under Pressure

Selecting the right PTFE material is critical for valve reliability in demanding applications. KINTEK specializes in manufacturing high-performance PTFE components—including custom valve seats, seals, and liners—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer tailored solutions from prototypes to high-volume orders, ensuring your PTFE components deliver unmatched chemical resistance, thermal stability, and mechanical integrity.

Don’t compromise on seal performance. Contact KINTEK today to discuss your specific requirements and let our experts help you select or fabricate the ideal PTFE solution for your high-performance butterfly valves.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications