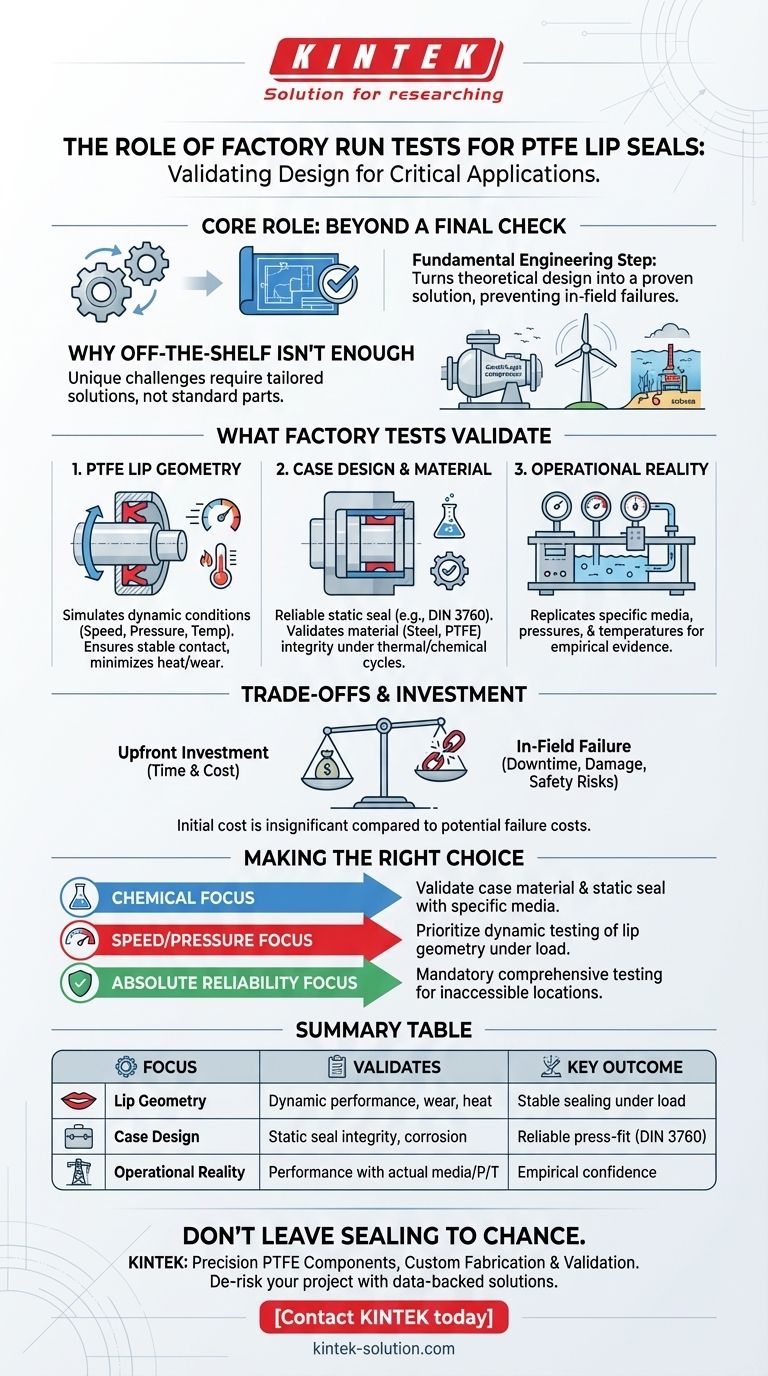

At their core, factory run tests for PTFE lip seals serve a critical validation role. They are not merely a final quality check; they are a fundamental engineering step that allows you and the manufacturer to make informed, data-driven decisions about the final seal design, specifically the lip profile and case construction, before it is deployed in a critical application.

The primary role of a factory run test is to transform a theoretical seal design into a proven solution. It simulates your specific operational conditions to confirm that the chosen lip geometry and materials will deliver reliable, long-term performance and prevent costly in-field failures.

Why Off-the-Shelf Isn't Always an Option

PTFE lip seals are specified for demanding environments where conventional elastomer seals fail. These applications—from centrifugal compressors and wind turbines to subsea wellheads and LNG equipment—present unique challenges that require a tailored sealing solution.

Validating the PTFE Lip Geometry

The precise shape and flexibility of the PTFE lip are paramount to its sealing function. A factory test simulates the dynamic conditions of your application, including rotational speed, pressure, and temperature.

This process confirms that the lip maintains stable contact with the shaft, providing an effective seal without generating excessive heat or wear, which are common failure points.

Confirming the Case Design and Material

The seal's outer case is responsible for providing a reliable static seal within the housing bore, often adhering to standards like DIN 3760 for interference fit.

Factory tests help validate your choice of material, whether it's standard mild steel, corrosion-resistant stainless steel (like JIS SUS 304), or even a 100% PTFE construction for extremely corrosive environments. The test ensures the case maintains its structural integrity and press-fit under thermal cycling and chemical exposure.

Simulating Your Operational Reality

The most valuable aspect of a factory run test is its ability to replicate your specific operating window. By using the actual media, pressures, and temperatures of your system, the test provides a clear and accurate preview of how the seal will perform in the real world.

This moves the conversation from design theory to empirical evidence, giving you confidence in the final product.

Understanding the Trade-offs

While invaluable, it's important to approach factory testing with a clear understanding of its purpose and limitations. This is not just a pass/fail inspection but a strategic investment.

Investment vs. In-Field Failure

Factory run tests require an upfront investment of both time and money. This initial cost, however, is insignificant when compared to the potential cost of unplanned downtime, equipment damage, or safety incidents caused by a seal failure in a critical system like an FPSO vessel or an API 6A wellhead.

Test Fidelity vs. Application Variables

A factory test is a highly accurate simulation, but it cannot always replicate every single variable of a complex operational environment over a multi-year lifespan. It is designed to mitigate the vast majority of risks associated with the core operating parameters, not to eliminate every conceivable edge case.

The goal of the test is to provide the highest possible degree of confidence that the fundamental design is sound for its intended purpose.

Making the Right Choice for Your Application

Use factory run tests as a strategic tool to de-risk your project and optimize performance.

- If your primary focus is chemical compatibility: Insist on tests that use your specific process media to validate the chosen case material (e.g., stainless steel vs. 100% PTFE) and its effect on the static seal.

- If your primary focus is high speed or pressure: Prioritize dynamic testing that confirms the stability and wear characteristics of the specific PTFE lip geometry under your most demanding operational loads.

- If your primary focus is absolute reliability in an inaccessible location: Treat a comprehensive factory run test as a mandatory project milestone to validate the entire seal assembly under a full range of simulated conditions.

Ultimately, leveraging factory run tests empowers you to specify and install a sealing solution with confidence, backed by objective performance data.

Summary Table:

| Test Focus | Validates | Key Outcome |

|---|---|---|

| Lip Geometry | Dynamic performance, wear, heat generation | Stable sealing contact under speed/pressure |

| Case Design/Material | Static seal integrity, corrosion resistance | Reliable press-fit per standards like DIN 3760 |

| Operational Reality | Performance with actual media, temperature, pressure | Empirical evidence for real-world confidence |

Don't leave your sealing performance to chance.

For critical applications in the semiconductor, medical, laboratory, and industrial sectors, a theoretical design is not enough. Factory run testing transforms your PTFE seal design into a proven, data-backed solution, mitigating the risk of costly in-field failures.

KINTEK manufactures precision PTFE components—including custom lip seals, liners, and labware. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your seals are validated for your exact operating conditions.

Contact KINTEK today to discuss how our factory run testing and custom fabrication capabilities can de-risk your next project and deliver reliable, long-term performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry