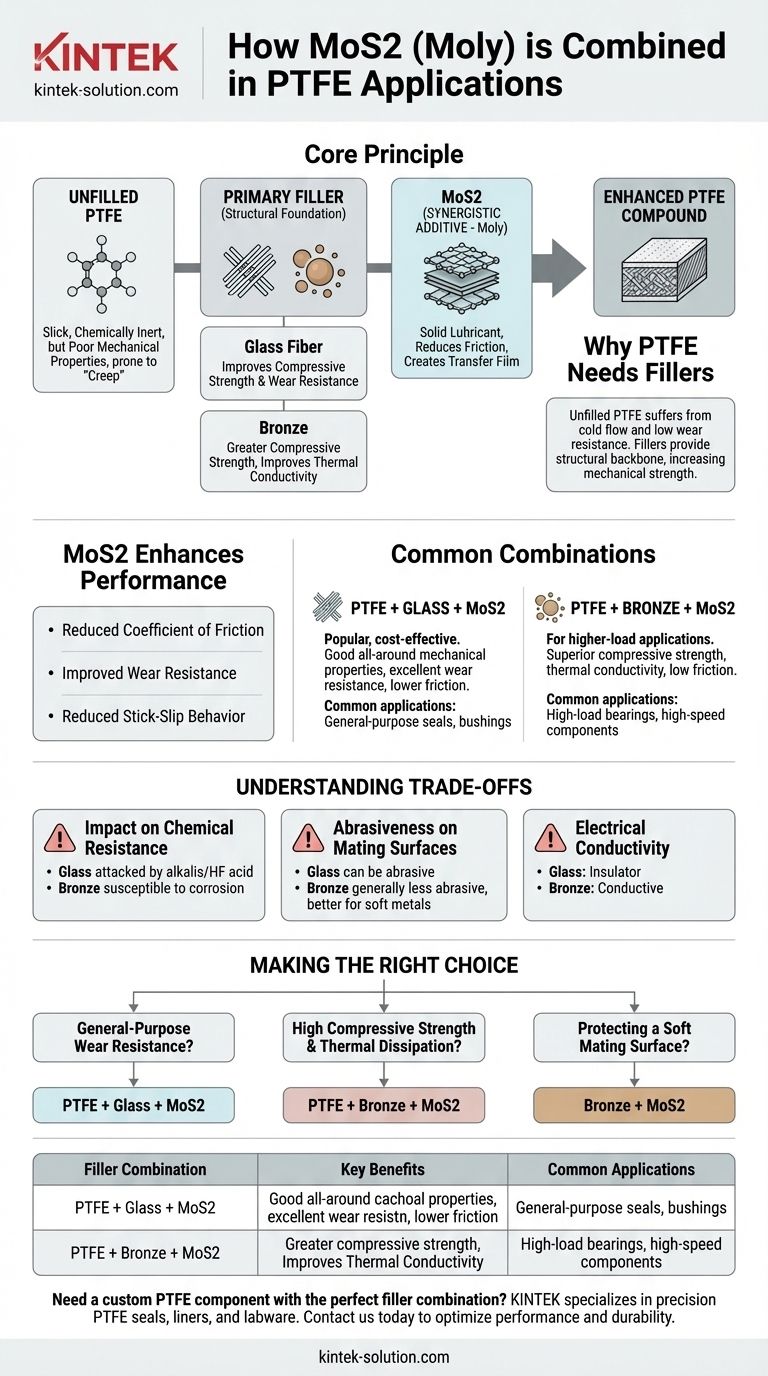

In practice, Molybdenum Disulfide (MoS2 or "Moly") is almost never used as a standalone filler in PTFE. Instead, it serves as a synergistic additive, typically combined with a primary structural filler like glass fiber or bronze. This combination enhances the properties of the base compound, primarily by reducing friction and improving wear characteristics.

The core principle is that MoS2 is not a primary filler but a secondary lubricant. It is added to PTFE compounds already filled with materials like glass or bronze to further decrease the coefficient of friction and improve the material's performance in sliding applications.

Why PTFE Needs Fillers

To understand the role of MoS2, we must first understand why pure, or "virgin," PTFE is often unsuitable for demanding mechanical applications.

The Problem with Unfilled PTFE

Unfilled PTFE is exceptionally slick and chemically inert, but it suffers from poor mechanical properties. Its primary weakness is creep, or "cold flow," where the material deforms permanently under a sustained load, even at room temperature. It also has very low wear resistance.

Primary Fillers: The Foundation

Primary fillers are added to the PTFE matrix to provide a structural backbone, drastically improving its mechanical strength and resistance to creep and wear.

The two most common foundational fillers used with MoS2 are glass fiber and bronze. Glass improves compressive strength and wear resistance, while bronze adds even greater compressive strength and improves thermal conductivity.

MoS2: The Synergistic Additive

Once a primary filler like glass or bronze provides the mechanical structure, MoS2 is added to refine the compound's performance, especially regarding friction.

MoS2 as a Solid Lubricant

MoS2 has a lamellar crystal structure, meaning it is composed of molecular layers that can easily slide over one another. When blended into a PTFE compound, it acts as a dry lubricant, reducing the coefficient of friction between the moving surfaces.

Enhancing Wear Properties

While primary fillers like glass increase wear resistance, they can sometimes be abrasive to the opposing surface. MoS2 helps by creating a thin, lubricious transfer film on the mating surface, which reduces stick-slip behavior and overall wear on both the PTFE component and the hardware.

The "Glass + Moly" Combination

A compound of PTFE with glass and MoS2 is a popular, cost-effective choice. It offers good all-around mechanical properties, excellent wear resistance, and a lower coefficient of friction than a glass-only filled material.

The "Bronze + Moly" Combination

For higher-load applications, a bronze and MoS2 filled PTFE is often specified. This combination provides superior compressive strength and thermal conductivity (from the bronze) along with the low-friction benefits of MoS2.

Understanding the Trade-offs

Adding any filler, including MoS2 and its partners, introduces compromises that are critical to consider.

Impact on Chemical Resistance

While PTFE is nearly universally inert, the fillers are not. Glass-filled compounds can be attacked by strong alkalis and hydrofluoric acid. Bronze fillers are susceptible to corrosion from certain chemicals.

Abrasiveness on Mating Surfaces

Glass fibers, in particular, can be abrasive to softer mating surfaces like aluminum or brass. While MoS2 mitigates this effect, it doesn't eliminate it. Bronze-filled compounds are generally less abrasive and are often preferred when running against softer metals.

Electrical Conductivity

Glass is an electrical insulator, making glass-filled compounds suitable for electrical applications. Bronze, being a metal, is electrically conductive, rendering any compound containing it unsuitable for applications requiring insulation.

Making the Right Choice for Your Application

The ideal formulation depends entirely on the specific demands of your operating environment and performance goals.

- If your primary focus is general-purpose wear resistance and chemical compatibility: A PTFE + Glass + MoS2 compound is often the most balanced and economical choice.

- If your primary focus is high compressive strength and thermal dissipation: A PTFE + Bronze + MoS2 compound is the superior option, especially for high-load bearing or high-speed sliding applications.

- If your primary focus is protecting a soft mating surface (like aluminum): A bronze-filled compound is generally a better choice than a glass-filled one, and the addition of MoS2 will further reduce friction and wear.

Choosing the correct filled PTFE is a matter of aligning the unique benefits of each additive with the specific challenges of your application.

Summary Table:

| Filler Combination | Key Benefits | Common Applications |

|---|---|---|

| PTFE + Glass + MoS2 | Good wear resistance, low friction, cost-effective | General-purpose seals, bushings |

| PTFE + Bronze + MoS2 | High compressive strength, thermal conductivity, low friction | High-load bearings, high-speed components |

Need a custom PTFE component with the perfect filler combination for your application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a PTFE + Glass + MoS2 formulation for general wear resistance or a PTFE + Bronze + MoS2 compound for high-load scenarios, we provide custom fabrication from prototypes to high-volume orders. Let us help you optimize performance and durability.

Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments