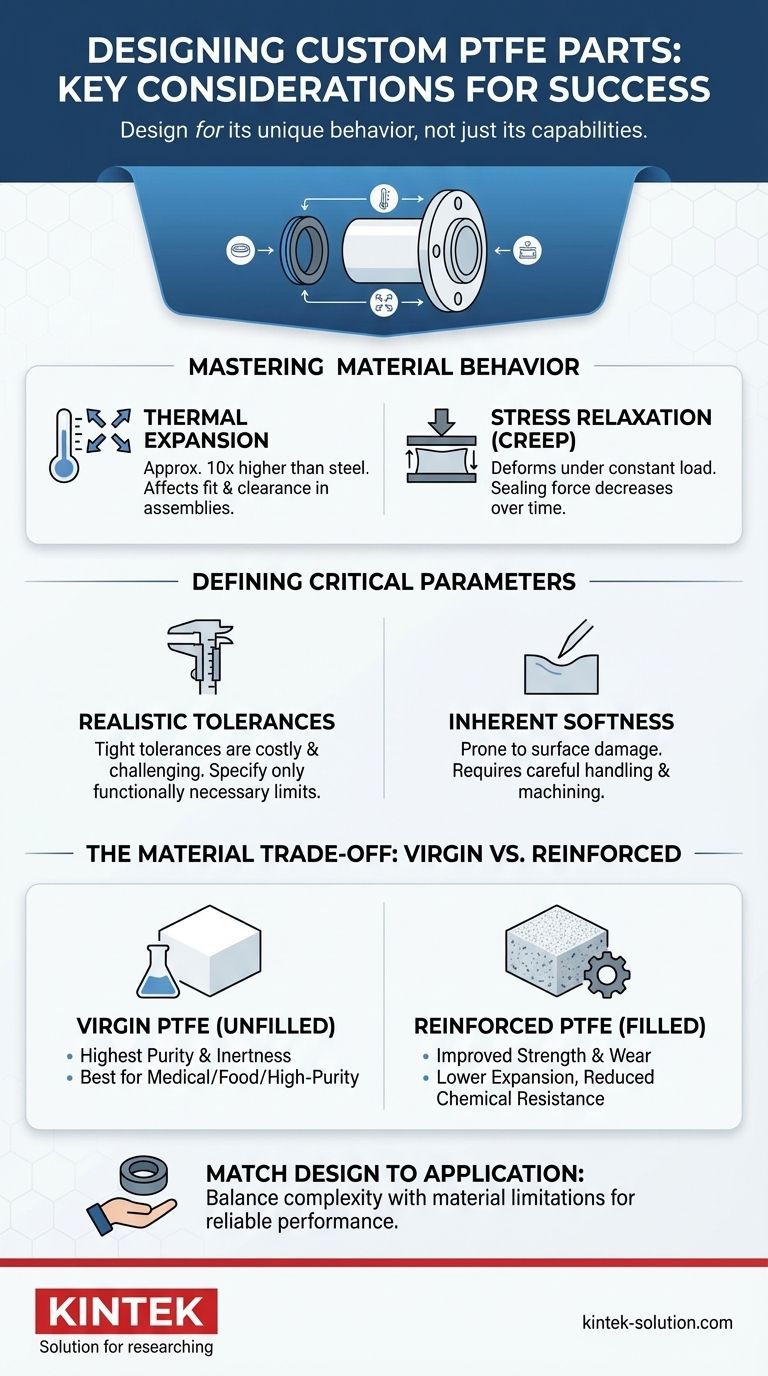

To design effective custom PTFE parts, you must move beyond standard material assumptions and account for PTFE's unique behaviors. The most critical considerations are its high rate of thermal expansion, its tendency to deform under load (stress relaxation), achieving realistic tolerances, and selecting the right material grade—either virgin or reinforced—for your specific operational environment.

The central challenge in PTFE part design is not its inherent capabilities, but its unique physical responses to temperature and pressure. Unlike metals, PTFE demands that you design for its behavior, particularly its thermal expansion and compressive creep, to ensure long-term performance and reliability.

Understanding PTFE's Core Material Behavior

Polytetrafluoroethylene (PTFE) is a high-performance polymer, but its properties are fundamentally different from metals or even other plastics. A successful design starts with respecting these core characteristics.

The Challenge of Thermal Expansion

PTFE has a coefficient of thermal expansion that is roughly ten times higher than that of steel. This is not a minor detail; it is a primary design constraint.

A part designed for a precise fit at room temperature may become too loose or too tight as operating temperatures fluctuate. This must be accounted for in clearance calculations, especially in assemblies with metal components.

Compressive Strength and Stress Relaxation

Under a constant compressive load, PTFE will slowly deform over time. This phenomenon is known as creep or stress relaxation.

For applications like seals and gaskets, this means the initial sealing force may decrease over time, potentially leading to leaks. Your design must account for this by considering the load, duration, and temperature of the application.

Inherent Softness and Surface Finish

PTFE is a relatively soft material, which makes it prone to surface damage during handling and installation. This property requires careful consideration for both the part's design and its post-machining handling procedures.

While smooth surface finishes are achievable, the material's softness dictates specific machining parameters, tool selection, and handling protocols to avoid scratches or imperfections.

Critical Design Parameters for Performance

Once you understand the material's behavior, you can focus on the specific parameters that define the part's function and reliability in its intended environment.

Defining Realistic Tolerances

While CNC machining can produce highly precise PTFE parts, the material's inherent properties make holding extremely tight tolerances challenging and costly.

Thermal expansion and softness mean that dimensions can shift with temperature changes or even during the measurement process itself. It is crucial to specify only the tolerances that are functionally necessary for the application.

Calculating Loads and Environmental Stresses

A thorough analysis of the part's operating conditions is non-negotiable. You must accurately calculate all mechanical loads the part will experience.

Equally important are environmental factors like chemical exposure and temperature extremes. These will directly influence material selection and the part's long-term stability.

Balancing Complexity with Material Limitations

PTFE's properties can limit certain design features. For example, creating extremely sharp internal corners can create stress points, while very thin walls may lack the necessary rigidity.

A successful design balances geometric complexity with the practical limitations of the material to ensure the final part is both functional and robust.

The Trade-off: Virgin vs. Reinforced PTFE

The choice between pure PTFE and a filled grade is one of the most important decisions you will make. Each has distinct advantages and is suited for different applications.

When to Specify Virgin PTFE

Virgin PTFE contains no fillers and offers the highest purity, lowest coefficient of friction, and best chemical inertness.

This makes it the mandatory choice for medical, pharmaceutical, food-grade, and high-purity semiconductor applications where contamination is not an option.

The Role of Fillers and Reinforcements

Adding fillers like glass, carbon, bronze, or graphite significantly enhances specific mechanical properties.

Reinforced grades offer improved compressive strength, reduced thermal expansion, and better wear resistance. However, these benefits often come at the cost of reduced chemical resistance and the introduction of potentially abrasive or contaminating filler materials.

How Manufacturing Method Influences Design

The final properties of a PTFE part are heavily influenced by how it is made. Your design should implicitly consider the manufacturing process.

Considerations for CNC Machining

Machining PTFE requires specialized knowledge. Factors like tool geometry, cutting speeds, and proper cooling are essential to avoid heat buildup, which can cause the material to deform and ruin dimensional accuracy.

Fixture design is also critical to hold the soft material securely without marring its surface or distorting its shape during the machining process.

The Impact of Compression Molding

For molded PTFE parts, the process parameters directly define the material's quality. Preforming pressure, sintering temperature, and the cooling rate all determine the final part's density, porosity, and mechanical integrity.

An improperly molded billet can lead to a part with poor performance, even if the subsequent machining is perfect.

Matching Your Design to Your Application

Use these guidelines to steer your design decisions based on your primary objective.

- If your primary focus is high purity or chemical inertness: Specify virgin PTFE and design for simple, cleanable geometries.

- If your primary focus is mechanical strength or dimensional stability: Select a reinforced grade and design around its improved compressive strength and lower thermal expansion.

- If your primary focus is precision sealing: Pay meticulous attention to stress relaxation and thermal expansion in your tolerance and clearance calculations.

- If your primary focus is cost-effectiveness: Avoid overly complex features and specify only functionally necessary tolerances to reduce machining time and difficulty.

By proactively designing for PTFE's unique material characteristics, you ensure your custom components will perform reliably and effectively in their intended application.

Summary Table:

| Design Consideration | Key Factor | Impact on Performance |

|---|---|---|

| Thermal Behavior | High coefficient of thermal expansion | Affects dimensional stability and fit in assemblies, especially with metal components. |

| Mechanical Load | Stress relaxation (creep) under load | Influences long-term sealing force and can lead to leaks if not accounted for. |

| Dimensional Control | Realistic tolerances | Critical for function; overly tight tolerances are challenging and costly due to material softness. |

| Material Selection | Virgin vs. Reinforced PTFE | Virgin offers highest purity/chemical resistance; filled grades improve strength/wear resistance. |

Ready to engineer high-performance custom PTFE components that are designed for success?

At KINTEK, we specialize in the precision manufacturing of custom PTFE parts—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your designs account for PTFE's unique behaviors, delivering reliable performance in even the most demanding applications.

We partner with you through every stage, from prototyping to high-volume production, ensuring your components meet exact specifications for purity, dimensional stability, and mechanical integrity.

Contact our PTFE experts today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications