At its core, dimensional stability is a major concern when machining PTFE because the material has two defining characteristics: an extremely high rate of thermal expansion and a tendency to deform under stress, a behavior known as creep. These properties mean a part can be perfectly dimensioned on the machine but change size or shape due to heat generated during cutting, changes in room temperature, or from the release of internal stresses.

The challenge with PTFE is not cutting it, but rather ensuring the finished part remains true to its intended dimensions long after the machining is complete. Success requires managing the material's inherent instability, not fighting against it.

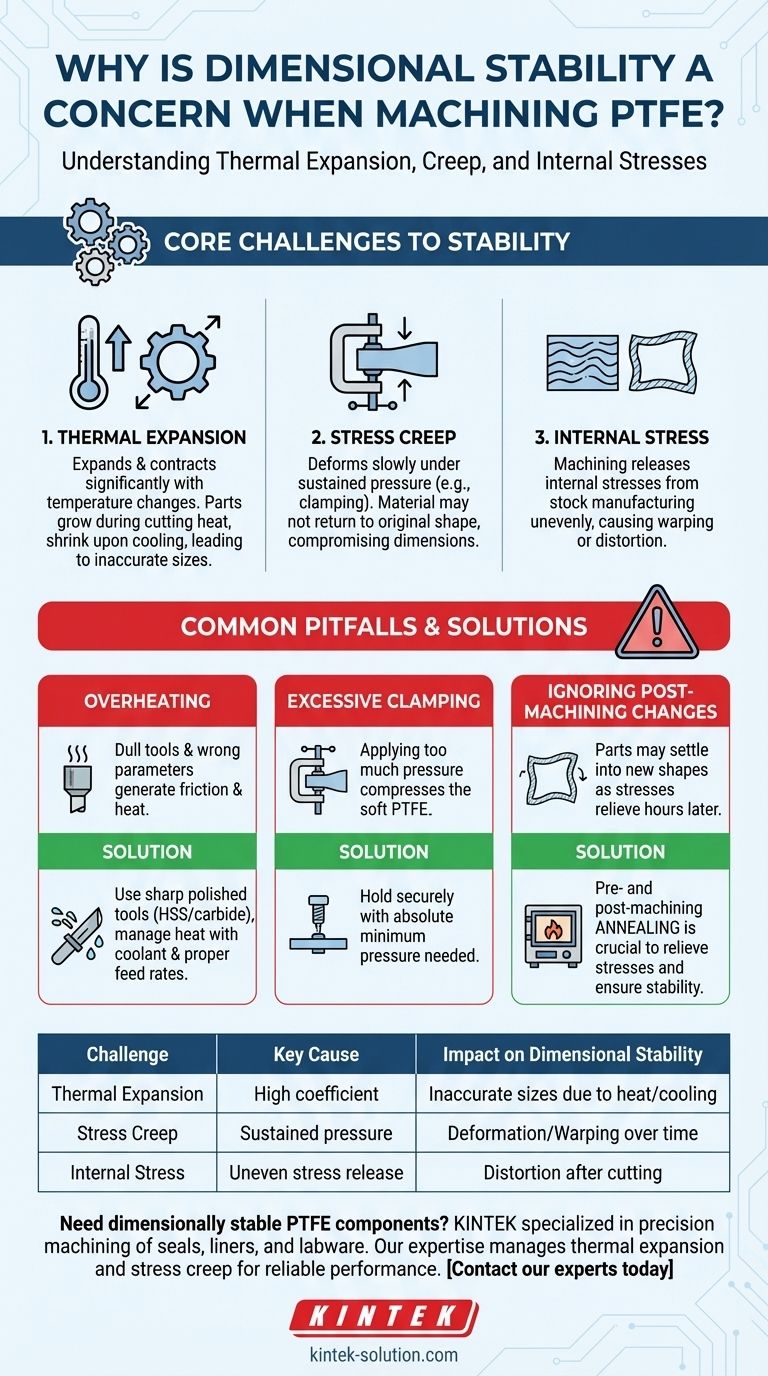

The Core Challenges to Dimensional Stability

To machine PTFE effectively, you must first understand the two primary material properties that work against dimensional accuracy.

High Coefficient of Thermal Expansion

PTFE expands and contracts with temperature changes far more than metals or even other plastics. This has significant implications during and after machining.

The heat generated by the cutting process alone can cause the material to expand, leading to an inaccurate cut. Once the part cools, it will contract to a smaller size than what was measured on the machine.

Even changes in ambient room temperature can alter a finished part's dimensions, making it difficult to hold tight tolerances if the operating environment is not controlled.

Stress Creep and Internal Memory

PTFE is a soft material that can "creep" or slowly deform when subjected to sustained pressure, such as from a vise or clamp. Over-tightening a fixture can compress the material, and it may not fully return to its original shape, compromising the final dimensions.

Furthermore, the process of manufacturing stock PTFE rods or sheets imparts internal stresses. As you machine away material, you release these stresses unevenly, which can cause the part to warp or distort.

Common Pitfalls in PTFE Machining

Many common machining practices that work for metals are counterproductive for PTFE and will exacerbate its inherent instability.

Overheating the Material

Using dull tools or incorrect cutting parameters is the most common mistake. This generates excessive friction and heat, maximizing the effects of thermal expansion and ruining accuracy.

While cutting speeds of 200 to 500 SFM are often recommended, the true goal is heat management. A sharp tool with a high feed rate can often evacuate chips and heat more efficiently than a slow cut that allows heat to build up.

Applying Excessive Clamping Pressure

It is easy to forget how soft PTFE is. Applying the same clamping force used for aluminum will compress the material, leading to dimensional errors and potentially inducing stress that causes long-term creep.

The goal is to hold the part securely with the absolute minimum pressure required.

Ignoring Post-Machining Changes

A part that is perfectly in-spec immediately after the final cut may be out-of-spec hours later. This happens as the part returns to ambient temperature or as relieved internal stresses cause it to settle into a new shape.

Without accounting for this, final inspection can be misleading.

Best Practices for Maintaining Stability

Successfully machining PTFE involves a strategic approach that accommodates the material's properties from start to finish.

Use Pre- and Post-Machining Annealing

Annealing is the most effective technique for ensuring stability. This process involves heating the material to a specific temperature and holding it there before cooling it slowly.

This relieves the internal stresses from the manufacturing process, creating a much more stable workpiece before you even begin cutting. A post-machining annealing cycle can provide a final stabilization.

Control Your Cutting Parameters

The right tools and settings are critical for minimizing heat and force.

Use extremely sharp, polished cutting tools, preferably High-Speed Steel (HSS) or carbide. A sharp edge shears the material cleanly rather than plowing through it, reducing heat and stress.

Employ feed rates between 0.002 and 0.010 inches per revolution to ensure the tool is cutting effectively, not just rubbing. Using a coolant can also be effective in managing thermal expansion during the cut.

Design for the Material's Nature

The most successful PTFE parts are designed with its properties in mind. This means incorporating tolerances that account for the expected thermal expansion in the part's final operating environment.

Do not expect PTFE to hold the same tight tolerances as steel or aluminum without specialized process controls.

Making the Right Choice for Your Goal

Your approach should be tailored to the specific requirements of the finished part.

- If your primary focus is achieving the highest precision: Your process must include a pre-machining annealing cycle and be performed in a temperature-controlled environment.

- If your primary focus is long-term part stability: Design the part with tolerances that accommodate thermal expansion and use post-machining annealing to relieve any stresses induced by the cutting process.

- If your primary focus is production efficiency: Invest in extremely sharp tooling and use a coolant system to manage heat, allowing for more aggressive yet controlled cutting parameters.

By understanding and respecting the unique properties of PTFE, you can reliably produce accurate and stable components.

Summary Table:

| Challenge | Key Cause | Impact on Dimensional Stability |

|---|---|---|

| Thermal Expansion | High coefficient of thermal expansion | Parts expand during cutting, contract after cooling, leading to inaccurate sizes. |

| Stress Creep | Material deforms under sustained pressure | Clamping force or internal stresses cause part to warp or change shape over time. |

| Internal Stress | Stresses from manufacturing stock shapes | Machining releases stress unevenly, causing part to distort after cutting is complete. |

Need dimensionally stable PTFE components? KINTEK specializes in precision machining of PTFE seals, liners, and labware for the semiconductor, medical, and laboratory industries. Our expertise in managing thermal expansion and stress creep ensures your parts meet exact specifications and remain stable in their operating environment. From prototypes to high-volume orders, we deliver reliable performance. Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications