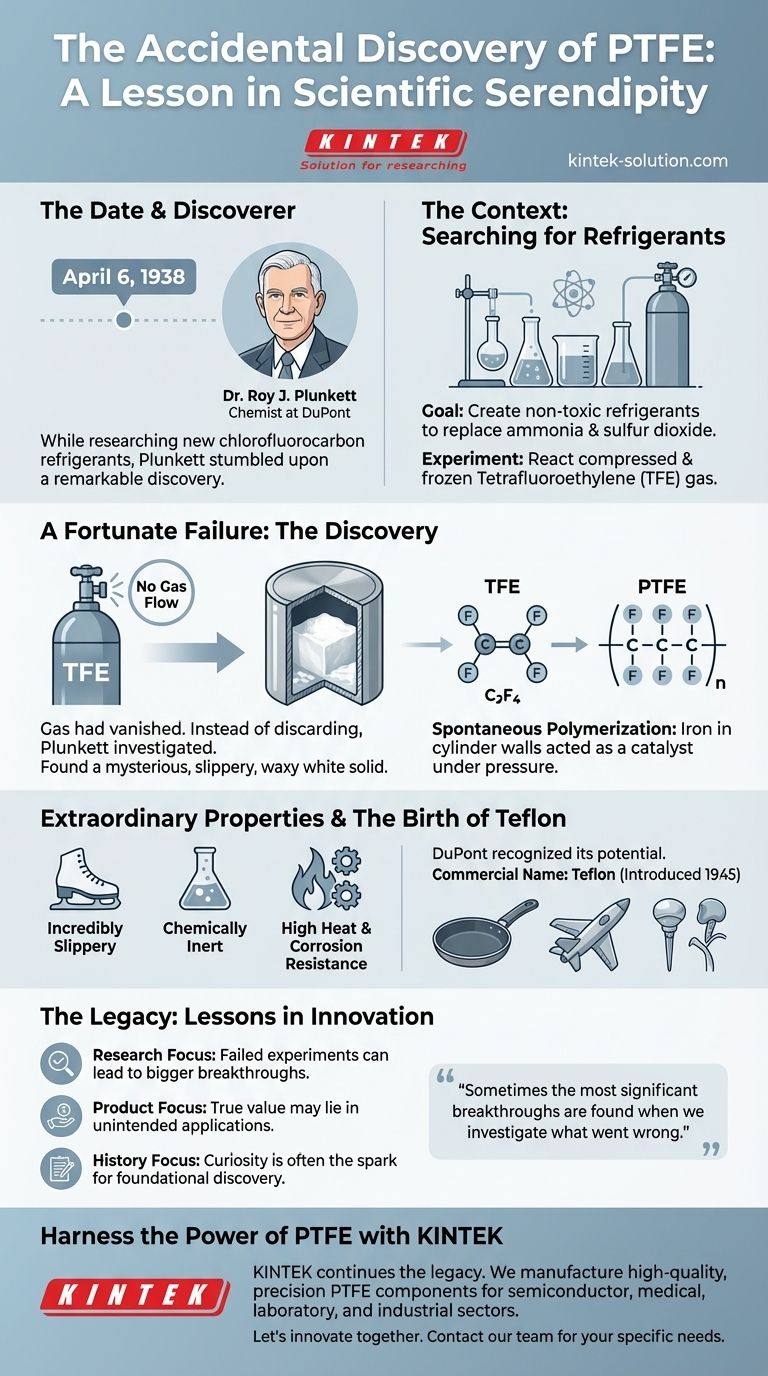

Polytetrafluoroethylene (PTFE) was discovered on April 6, 1938, by Dr. Roy J. Plunkett. The discovery was entirely accidental, occurring while Plunkett, a chemist for DuPont, was researching new chlorofluorocarbon refrigerants. Instead of a new gas, he found a mysterious, waxy white solid with remarkable properties.

The discovery of PTFE is a classic case of scientific serendipity. A failed experiment with refrigerant gas led to the creation of a completely new material with extraordinary characteristics, proving that sometimes the most significant breakthroughs are found when we investigate what went wrong.

The Context of the Discovery

The Search for a New Refrigerant

In the 1930s, chemical company DuPont was focused on developing new, non-toxic refrigerants to replace existing options like ammonia and sulfur dioxide.

Dr. Roy J. Plunkett was assigned to this research, specifically exploring chlorofluorocarbon-based gases.

The Experiment with TFE Gas

The experiment on April 6, 1938, involved a cylinder of tetrafluoroethylene (TFE) gas that had been compressed and frozen.

The plan was to react this TFE gas with other chemicals to create a new refrigerant compound.

A Fortunate Failure

An Unexpected Problem

When Plunkett and his assistant prepared to use the TFE, they found that no gas came out of the cylinder's valve. The bottle's weight, however, indicated it was still full.

Instead of flowing as expected, the gas inside had seemingly vanished.

Investigating the Anomaly

Driven by curiosity, Plunkett refused to discard the cylinder. He sawed the metal container open to investigate what had happened.

Inside, he did not find the expected gas but a slippery, waxy, white solid that coated the container's inner walls.

The Accidental Polymerization

Plunkett realized the individual TFE gas molecules had spontaneously polymerized—linking together into long chains—to form a new solid substance.

This new material was Polytetrafluoroethylene, or PTFE. The iron from the container's interior walls had inadvertently acted as a catalyst for the reaction under the high pressure.

From Lab Curiosity to Global Material

Extraordinary Properties

The newly discovered substance was unlike anything seen before. It was incredibly slippery (possessing a very low coefficient of friction), chemically inert, and highly resistant to heat and corrosion.

DuPont immediately recognized the potential of this unique material and began to study it further.

The Birth of Teflon

PTFE would later be patented and introduced commercially under the brand name Teflon in 1945.

Its non-stick properties first gained fame in cookware, but its applications quickly expanded into countless industrial, aerospace, and medical fields.

The Legacy of Plunkett's Discovery

The story of PTFE's creation offers timeless lessons that extend beyond the chemistry lab.

- If your primary focus is research and innovation: Remember that investigating anomalies and failed experiments can often lead to more significant discoveries than the original goal.

- If your primary focus is product development: This case proves that a material's true value may be in an application completely unrelated to its intended purpose.

- If your primary focus is understanding scientific history: Plunkett's discovery is a prime example of how curiosity, rather than a planned objective, is often the critical spark for foundational breakthroughs.

Ultimately, the discovery of PTFE is a powerful reminder that paying attention to the unexpected is a cornerstone of innovation.

Summary Table:

| Aspect | Details |

|---|---|

| Date of Discovery | April 6, 1938 |

| Discoverer | Dr. Roy J. Plunkett |

| Company | DuPont |

| Discovery Context | Researching new refrigerants |

| Key Property | Spontaneous polymerization of TFE gas |

| Commercial Name | Teflon (introduced in 1945) |

Harness the Power of PTFE for Your Precision Applications

The story of PTFE's discovery is a testament to the power of innovation. At KINTEK, we continue this legacy by manufacturing high-quality, precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our custom fabrication expertise ensures you get the reliable, chemically inert, and high-performance parts your projects demand.

Let's innovate together. Contact our team today to discuss your specific needs and discover how our PTFE solutions can benefit your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers