In short, Polytetrafluoroethylene (PTFE) is used in industrial processes in three primary forms: as a high-performance coating, as a core material for valves and seals, and as custom machined parts. Its value stems from a unique ability to resist extreme heat, harsh chemicals, and abrasion while providing a nonstick, low-friction surface.

The core reason PTFE is indispensable in industry is not just one of its properties, but its rare capacity to maintain multiple elite characteristics—chemical inertness, thermal stability, and low friction—simultaneously, even under the most demanding operational conditions.

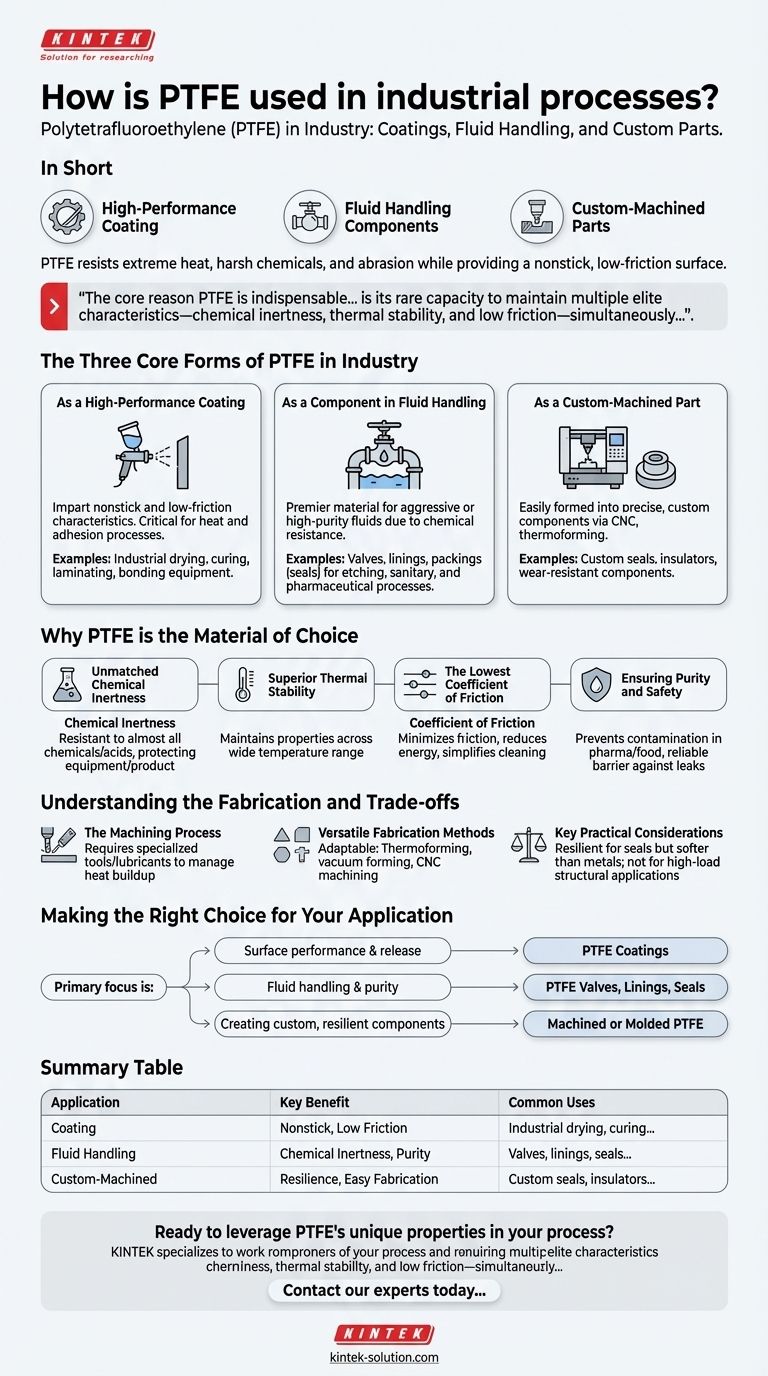

The Three Core Forms of PTFE in Industry

PTFE's versatility allows it to be integrated into processes in several distinct ways, each leveraging a different aspect of its unique chemical and physical properties.

As a High-Performance Coating

PTFE coatings are applied to surfaces to impart nonstick and low-friction characteristics. This is critical in processes that involve heat and potential adhesion.

Applications include industrial drying, curing, laminating, and bonding equipment, where the coating prevents material buildup and ensures a smooth, continuous operation.

As a Component in Fluid Handling

Due to its exceptional resistance to corrosion and acids, PTFE is a premier material for components that manage aggressive or high-purity fluids.

PTFE valves, linings, and packings (seals) are essential for safely transferring chemicals in etching or sanitary processes. In pharmaceutical research, PTFE septas ensure sample integrity by preventing contamination.

As a Custom-Machined Part

PTFE can be easily formed into precise, custom components using standard methods like CNC machining, thermoforming, or vacuum forming.

Its natural resilience allows machined parts to conform well to working dimensions, sometimes reducing the need for extremely tight tolerances. This makes it ideal for creating custom seals, insulators, or wear-resistant components for specialized equipment.

Why PTFE is the Material of Choice

The preference for PTFE in critical applications comes down to its ability to solve persistent industrial challenges related to durability, safety, and efficiency.

Unmatched Chemical Inertness

PTFE is virtually inert and resistant to almost all industrial chemicals and acids. This makes it the default choice for containing or transferring corrosive materials, protecting both the equipment and the product from degradation.

Superior Thermal Stability

The material maintains its key properties across a wide temperature range. This stability is crucial for components used in high-temperature curing ovens or other heat-intensive processes where lesser materials would fail.

The Lowest Coefficient of Friction

Known for its exceptional nonstick surface, PTFE minimizes friction between moving parts and prevents process materials from sticking to equipment. This reduces energy consumption and simplifies cleaning and maintenance.

Ensuring Purity and Safety

In industries like pharmaceuticals and food processing, preventing contamination is paramount. High-quality PTFE packings and seals create a reliable barrier, preventing leaks that could compromise product purity or endanger personnel.

Understanding the Fabrication and Trade-offs

While highly effective, working with PTFE involves specific considerations to maximize its benefits. Understanding its properties is key to successful application.

The Machining Process

Though easily machined, PTFE requires specialized cutting tools and the use of lubricants. This is necessary to manage heat buildup during the machining operation, which can otherwise affect the final dimensions and integrity of the part.

Versatile Fabrication Methods

PTFE's adaptability is a significant advantage. It can be thermoformed by heating and molding sheets, vacuum-formed into hollow shapes, or precision-cut via CNC machining, allowing for the creation of highly specialized parts.

Key Practical Considerations

The resilience of PTFE is a major benefit, allowing it to create tight seals. However, this also means it is a softer material than metals and is not intended for high-load structural applications. Its performance is optimized when used for its surface and chemical properties, not its mechanical strength.

Making the Right Choice for Your Application

Selecting the correct form of PTFE is essential for optimizing your industrial process and achieving the desired performance and reliability.

- If your primary focus is surface performance and release: PTFE coatings are the most direct solution for nonstick, low-friction needs in processes like bonding or curing.

- If your primary focus is fluid handling and purity: PTFE valves, linings, and seals are essential for safely managing corrosive chemicals or high-purity liquids.

- If your primary focus is creating custom, resilient components: Machined or molded PTFE is ideal for parts that require chemical resistance and must conform to specific working dimensions.

Ultimately, leveraging PTFE is about matching its unique combination of properties to the specific demands of your process to ensure superior safety, efficiency, and long-term reliability.

Summary Table:

| Application | Key Benefit | Common Uses |

|---|---|---|

| High-Performance Coating | Nonstick, Low Friction | Industrial drying, curing, laminating equipment |

| Fluid Handling Components | Chemical Inertness, Purity | Valves, linings, seals for corrosive/sanitary processes |

| Custom-Machined Parts | Resilience, Easy Fabrication | Custom seals, insulators, wear-resistant components |

Ready to leverage PTFE's unique properties in your process?

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, valves, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure superior chemical resistance, thermal stability, and nonstick performance in every part, from prototypes to high-volume orders.

Contact our experts today to discuss your specific application and receive a custom solution that enhances your process safety, efficiency, and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications