To put it simply, CNC machined PTFE parts are critical components in the medical, electrical, and food and beverage industries. Their widespread use is a direct result of PTFE's unique combination of properties: it is biocompatible, an excellent electrical insulator, chemically inert, and safe for direct contact with food.

The real insight is not just where PTFE is used, but why. PTFE is a problem-solving material, and CNC machining is the process that unlocks its potential by shaping it with the precision required for high-stakes applications like surgical tools, electrical insulators, and food-safe seals.

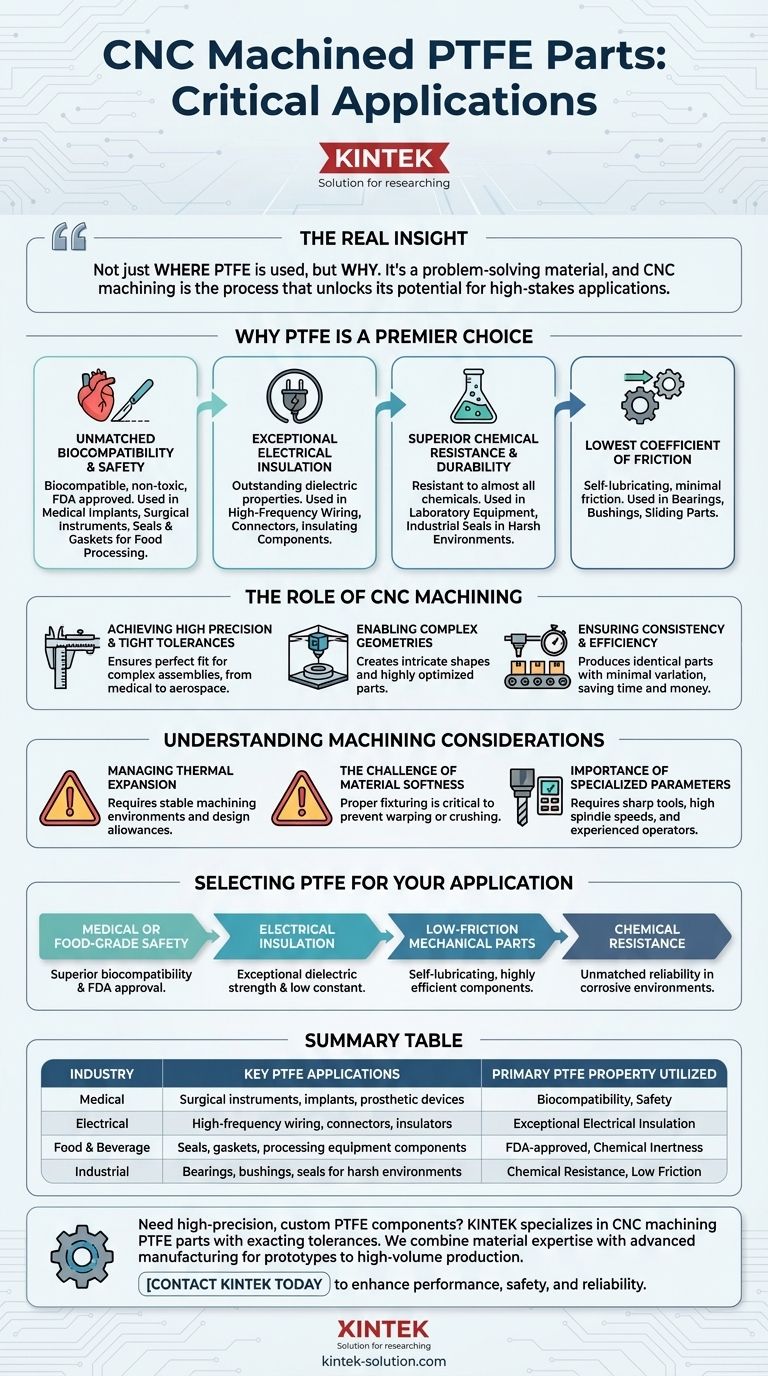

Why PTFE is a Premier Choice for Critical Applications

The value of PTFE (Polytetrafluoroethylene) stems from a set of inherent material characteristics that make it uniquely suited for environments where other polymers would fail.

Unmatched Biocompatibility and Safety

PTFE is biocompatible, meaning it does not react with bodily tissues or fluids. This makes it a go-to material for medical implants, prosthetic devices, and surgical instruments.

Furthermore, its non-toxic nature and FDA approval for food contact applications make it essential for seals, gaskets, and components in food processing equipment.

Exceptional Electrical Insulation

PTFE has outstanding dielectric properties, making it one of the best electrical insulators available. This is why it is extensively used for high-frequency wiring, connectors, and insulating components in the electrical and electronics industries.

Superior Chemical Resistance and Durability

This material is remarkably resistant to almost all chemicals and solvents. This inertness ensures its durability and reliability in harsh chemical environments, such as in laboratory equipment or industrial seals that are exposed to corrosive substances.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating property makes it ideal for bearings, bushings, and sliding parts where low friction is paramount.

The Role of CNC Machining in Unlocking PTFE's Potential

While PTFE's properties are impressive, they are only useful if the material can be formed into precise, functional parts. This is where CNC (Computer Numerical Control) machining becomes essential.

Achieving High Precision and Tight Tolerances

CNC machining allows for the creation of PTFE parts with extremely tight tolerances, which is critical for performance in complex assemblies. The process provides a level of accuracy that ensures components fit and function perfectly, from medical devices to aerospace seals.

Enabling Complex Geometries

Modern CNC equipment can execute complex tool paths to create intricate shapes and features. This capability allows engineers to design highly optimized PTFE parts without being constrained by the limitations of other manufacturing methods.

Ensuring Consistency and Efficiency

Once a design is programmed, CNC machines can produce thousands of identical parts with minimal variation. This repeatability is crucial for quality control and makes the process highly efficient, saving both time and money in production.

Understanding the Trade-offs and Machining Considerations

Despite being relatively easy to machine, achieving high-quality results with PTFE requires a deep understanding of its unique behavior. Ignoring these factors can lead to poor quality and part failure.

Managing Thermal Expansion

PTFE has a high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. Machining environments must be kept stable, and designs must account for this behavior to maintain dimensional accuracy in the final application.

The Challenge of Material Softness

PTFE is a soft material, which can lead to warping or deformation if not handled correctly. Proper fixture design is critical to hold the workpiece securely without crushing or damaging it during the machining process.

Importance of Specialized Parameters

Success with PTFE requires optimizing machining parameters. This includes using very sharp cutting tools, managing high spindle speeds and feed rates, and often forgoing liquid coolant to prevent thermal shock and maintain part quality. Operator experience is invaluable for making these adjustments.

Selecting PTFE for Your Specific Application

Choosing the right material is about aligning its properties with your primary goal.

- If your primary focus is medical or food-grade safety: PTFE's biocompatibility and FDA approval make it a superior and often non-negotiable choice.

- If your primary focus is electrical insulation: PTFE’s exceptional dielectric strength and low dielectric constant are critical for high-frequency and high-voltage applications.

- If your primary focus is low-friction mechanical parts: Its self-lubricating nature is ideal for creating highly efficient bearings, seals, and sliding components that require no external lubrication.

- If your primary focus is chemical resistance: PTFE's inertness provides unmatched reliability for parts used in corrosive or harsh chemical processing environments.

Ultimately, leveraging PTFE effectively depends on pairing its inherent strengths with the precision of modern CNC machining.

Summary Table:

| Industry | Key PTFE Applications | Primary PTFE Property Utilized |

|---|---|---|

| Medical | Surgical instruments, implants, prosthetic devices | Biocompatibility, Safety |

| Electrical | High-frequency wiring, connectors, insulators | Exceptional Electrical Insulation |

| Food & Beverage | Seals, gaskets, processing equipment components | FDA-approved, Chemical Inertness |

| Industrial | Bearings, bushings, seals for harsh environments | Chemical Resistance, Low Friction |

Need high-precision, custom PTFE components for your critical application?

KINTEK specializes in CNC machining PTFE parts with the exacting tolerances required by the semiconductor, medical, laboratory, and industrial sectors. We combine material expertise with advanced manufacturing to deliver superior seals, liners, labware, and more—from prototypes to high-volume production.

Contact KINTEL today to discuss how our precision PTFE solutions can enhance your product's performance, safety, and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications