The significance of Polytetrafluoroethylene (PTFE) lies in its rare and powerful combination of properties that were previously unavailable in a single material. Its extreme low friction, chemical inertness, and high-temperature resistance make it a unique problem-solver that prevents leaks, reduces wear, and ensures safety in countless industrial, medical, and consumer applications.

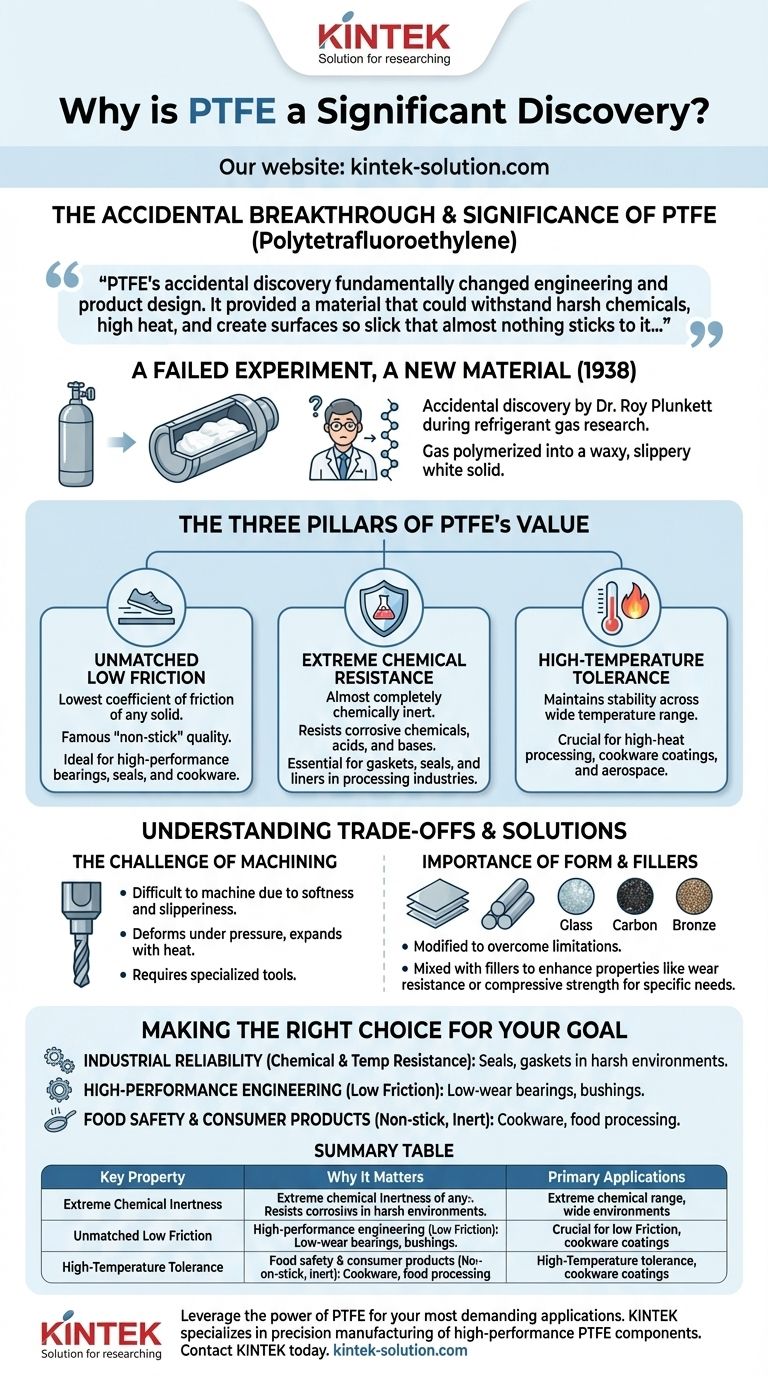

PTFE's accidental discovery fundamentally changed engineering and product design. It provided a material that could withstand harsh chemicals, high heat, and create surfaces so slick that almost nothing sticks to it, revolutionizing everything from industrial seals to non-stick cookware.

The Accidental Breakthrough

PTFE, widely known by its DuPont brand name Teflon, was not the product of intentional design. Its discovery was a complete accident that highlights the nature of scientific progress.

A Failed Experiment, A New Material

In 1938, Dr. Roy Plunkett, a chemist at DuPont, was working to develop a new, non-toxic refrigerant gas. He stored the gas in a pressurized cylinder, but when he opened the valve, nothing came out, even though the cylinder's weight indicated it was still full.

The Waxy, Slippery Discovery

Driven by curiosity, Plunkett sawed the cylinder open. Inside, he found that the gas had polymerized—forming molecular chains—into a strange, waxy white solid. This new substance was incredibly slippery and seemed unaffected by any solvents he used to try and remove it. This was the world's first encounter with PTFE.

The Three Pillars of PTFE's Value

The significance of PTFE stems from three core properties that make it a benchmark material across multiple industries.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This creates its famous "non-stick" or "slippery" quality.

This property is critical for applications like high-performance bearings, seals, and non-stick surface coatings on cookware. It dramatically reduces wear and energy loss in mechanical systems.

Extreme Chemical Resistance

PTFE is almost completely chemically inert, meaning it does not react with the vast majority of corrosive chemicals, acids, and bases.

This makes it an essential material for gaskets, seals, and linings in the chemical processing and manufacturing industries. It safely contains hazardous substances and prevents costly, dangerous leaks.

High-Temperature Tolerance

The material maintains its stability and structure across a wide range of temperatures. This thermal resistance is crucial for its use in both industrial and consumer goods.

In the food and beverage industry, this allows PTFE to be used for non-stick cookware and as coatings or seals for containers that undergo high-heat processing, ensuring both safety and efficiency.

Understanding the Trade-offs

Despite its remarkable advantages, PTFE is not a perfect material. Its unique properties also introduce specific challenges that require specialized handling.

The Challenge of Machining

The very properties that make PTFE valuable—its softness and slipperiness—also make it difficult to machine.

It has a tendency to deform under pressure rather than cutting cleanly. Heat generated during machining can also cause it to expand, making it difficult to hold tight tolerances without specialized tools and techniques.

The Importance of Form and Fillers

To overcome its limitations and enhance its properties for specific uses, pure PTFE is often modified. It is available in various forms, including compressed sheets, and can be mixed with fillers like glass, carbon, or bronze.

These variations alter the material's performance characteristics, such as wear resistance or compressive strength, allowing engineers to tailor it to precise operational needs in fields from aerospace to medical equipment.

Making the Right Choice for Your Goal

Selecting PTFE or one of its variants depends entirely on the primary problem you need to solve.

- If your primary focus is industrial reliability: The combination of chemical inertness and temperature resistance makes it the definitive choice for seals and gaskets in harsh environments.

- If your primary focus is high-performance engineering: Its benchmark low coefficient of friction is the key property for creating low-wear bearings, bushings, and other components where reducing friction is critical.

- If your primary focus is food safety or consumer products: Its non-stick nature and chemical stability make it an ideal, safe material for cookware and food processing equipment.

Ultimately, PTFE remains a cornerstone of modern material science because it solves fundamental engineering challenges that few other materials can address so effectively.

Summary Table:

| Key Property | Why It Matters | Primary Applications |

|---|---|---|

| Extreme Chemical Inertness | Resists almost all acids, bases, and solvents; prevents leaks and corrosion. | Chemical processing seals, liners, labware. |

| Unmatched Low Friction | Lowest coefficient of friction of any solid; reduces wear and energy loss. | Non-stick coatings, bearings, bushings. |

| High-Temperature Tolerance | Maintains stability and performance across a wide temperature range. | High-heat seals, cookware coatings, aerospace components. |

Leverage the power of PTFE for your most demanding applications. KINTEK specializes in the precision manufacturing of high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures reliability in harsh environments. Contact KINTEK today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance