In heat press applications, the most common alternatives to a Teflon sheet are parchment paper and silicone sheets. While both can serve as a protective barrier in a pinch, they come with significant differences in durability, reusability, and overall performance compared to the industry-standard Teflon sheet.

The core issue isn't just finding a substitute, but understanding the trade-offs between cost, reusability, and reliability. While alternatives like parchment paper work for emergencies, a Teflon sheet remains the superior investment for consistent, professional results.

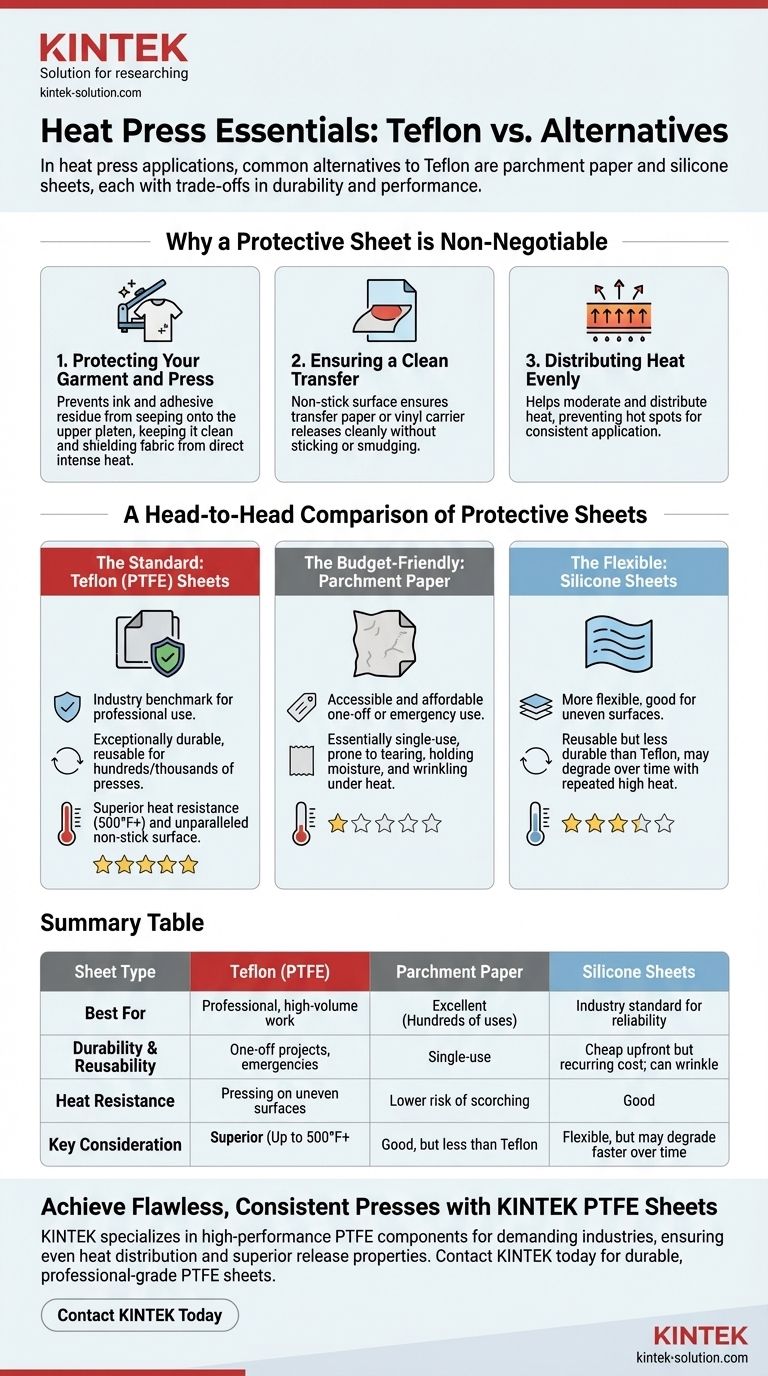

Why a Protective Sheet is Non-Negotiable

Before comparing alternatives, it's critical to understand the function of a protective sheet. It's not an optional accessory; it's essential for quality and safety in heat pressing.

Protecting Your Garment and Press

A protective sheet acts as a crucial barrier. It prevents ink, dye, and adhesive residue from your transfer from seeping onto the upper platen of your heat press, keeping it clean for future projects.

Simultaneously, it shields your garment from direct, intense heat, which helps prevent scorching or yellowing of the fabric.

Ensuring a Clean Transfer

The non-stick surface is the most important feature. This property ensures that when you open the press, the transfer paper or vinyl carrier sheet releases cleanly without sticking to the platen or smudging your design.

Distributing Heat Evenly

A quality sheet helps to moderate and distribute the heat from the platen more evenly across the surface of your design. This can help prevent hot spots and ensure a more consistent application.

A Head-to-Head Comparison of Protective Sheets

Each type of protective sheet offers a distinct set of advantages and disadvantages. The right choice depends on your project volume, budget, and desired quality.

The Standard: Teflon (PTFE) Sheets

Teflon sheets, technically Polytetrafluoroethylene (PTFE), are the industry benchmark for a reason. They are exceptionally durable and can be reused for hundreds, if not thousands, of presses.

Their primary benefits are superior heat resistance (often up to 500°F or more) and an unparalleled non-stick surface, providing the most reliable and clean transfer possible.

The Budget-Friendly Option: Parchment Paper

Parchment paper is the most accessible and affordable alternative. It's readily available and can work if you have no other option.

However, it is essentially a single-use product. It is prone to tearing, can hold moisture, and may wrinkle under heat, potentially imprinting unwanted textures onto your design.

The Flexible Contender: Silicone Sheets

Silicone sheets are another heat-resistant option. They are more flexible than Teflon sheets, which can be useful in certain applications.

While they are reusable, they are generally considered less durable than Teflon. They may degrade or lose their non-stick properties more quickly over time with repeated high-heat use.

Understanding the Trade-offs: Cost vs. Longevity

Choosing an alternative to Teflon is a balancing act. What you save in upfront cost, you may lose in reliability and longevity.

Reusability and Long-Term Value

A Teflon sheet is a small, one-time investment that pays for itself through reusability. Parchment paper, while cheap per sheet, becomes a recurring operational cost.

If you plan to do more than a handful of projects, the cost of replacing parchment paper will quickly exceed the price of a single Teflon sheet.

Heat Resistance and Reliability

Teflon offers the most consistent and highest level of heat resistance. This reliability is crucial when working with a variety of materials and transfer types that require precise temperature control.

Using a material like parchment paper, which has a lower heat tolerance, introduces a risk of scorching or failure during the pressing process.

What Not to Use

Never use a standard household item like a dish towel. It lacks the non-stick properties required for a clean release and can easily scorch, ruining both your garment and your heat press platen.

Making the Right Choice for Your Project

Your decision should be guided by your specific goals and frequency of use.

- If your primary focus is professional quality and high volume: Invest in a quality Teflon (PTFE) sheet. Its durability and reliability are unmatched and will save you money and frustration in the long run.

- If your primary focus is a one-off project or an emergency fix: High-quality, un-waxed parchment paper is a viable, low-cost solution to get the job done.

- If your work involves pressing on uneven surfaces: A flexible silicone sheet might offer an advantage, but be prepared for it to have a shorter lifespan than Teflon.

Ultimately, understanding the properties of each material empowers you to select the right tool for a perfect press every time.

Summary Table:

| Sheet Type | Best For | Durability & Reusability | Heat Resistance | Key Consideration |

|---|---|---|---|---|

| Teflon (PTFE) | Professional, high-volume work | Excellent (Hundreds of uses) | Superior (Up to 500°F+) | Industry standard for reliability and clean transfers |

| Parchment Paper | One-off projects, emergencies | Single-use | Lower risk of scorching | Cheap upfront but a recurring cost; can wrinkle |

| Silicone Sheets | Pressing on uneven surfaces | Good, but less than Teflon | Good | Flexible, but may degrade faster over time |

Achieve Flawless, Consistent Presses with KINTEK PTFE Sheets

Stop compromising on quality with temporary fixes. For professional heat press applications that demand reliability, durability, and a perfect non-stick surface every time, the right PTFE (Teflon) sheet is essential.

KINTEK specializes in manufacturing high-performance PTFE components—including heat press sheets—for demanding industries. We prioritize precision production to ensure even heat distribution and superior release properties, protecting your equipment and guaranteeing clean transfers.

Whether you need a standard size or a custom-fabricated solution for a unique application, we support you from prototype to high-volume orders.

Ready to invest in a sheet that performs as hard as you do? Contact KINTEK today to discuss your needs and get a quote for durable, professional-grade PTFE sheets.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How do ePTFE gaskets form a seal when installed? By Flowing to Create a Perfect Seal

- In what types of cables is PTFE commonly used? For High-Performance Applications

- Is carbon filler more or less abrasive than glass filler in PTFE? Protect Your Mating Surfaces

- What role does Teflon play in automotive applications? Enhancing Durability & Performance in Harsh Environments

- What temperature limitations exist for PTFE lined butterfly valves? Ensure Safe, Leak-Free Operation

- What is a PTFE lined butterfly valve and how does it work? Control Corrosive & Pure Fluids Safely

- How do PTFE seals and rings contribute to environmental compliance? Ensure Leak-Proof Operations

- What efficiency benefits do PTFE lip seals provide in aerospace applications? Reduce Fuel Costs & Boost Reliability