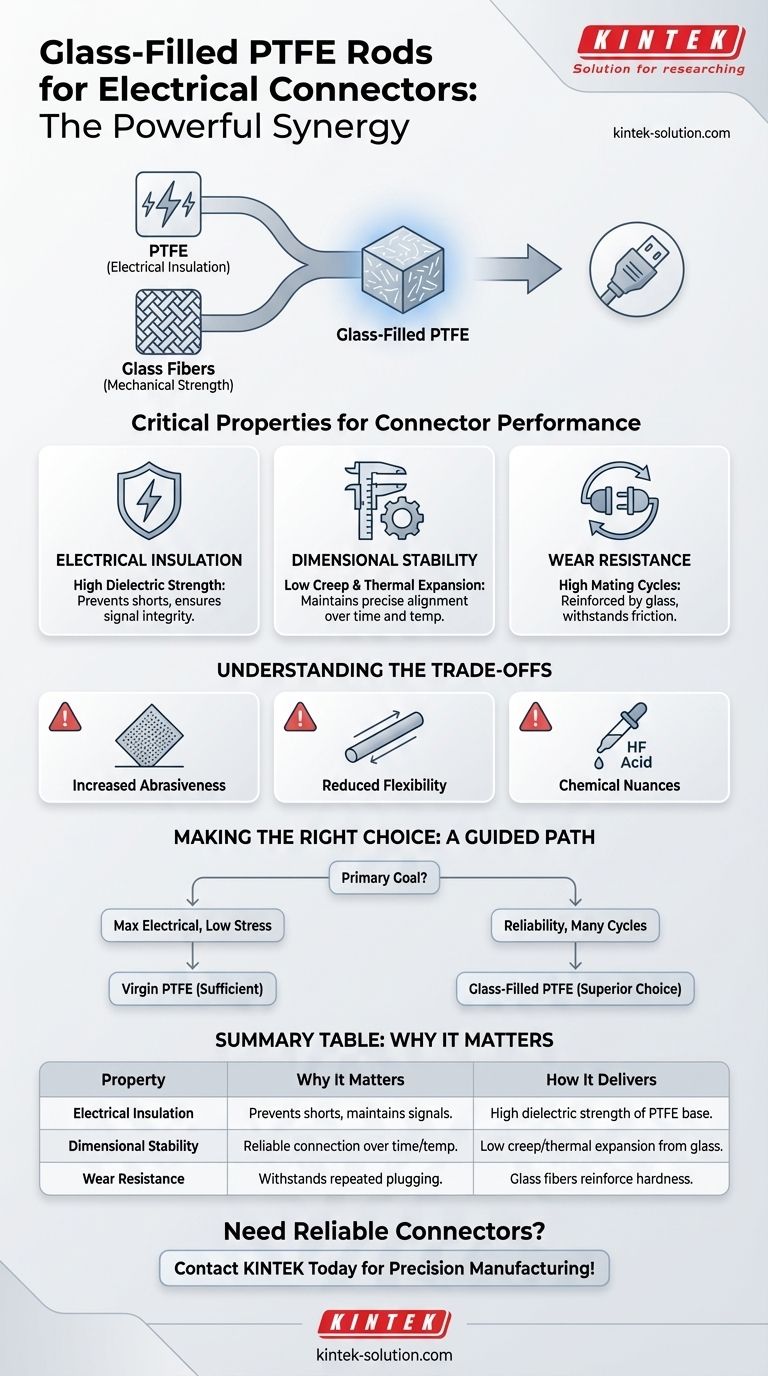

At its core, the suitability of glass-filled PTFE for electrical connectors comes from a powerful synergy. The material combines the exceptional electrical insulation of Polytetrafluoroethylene (PTFE) with the mechanical enhancements provided by glass fibers, resulting in a component that is not only a superb insulator but also dimensionally stable and highly resistant to physical wear.

The critical insight is that adding glass fibers transforms PTFE from a soft, deformable insulator into a rigid, reliable structural material. This allows it to withstand the combined electrical, thermal, and mechanical stresses inherent in high-performance connector applications.

The Critical Properties for Connector Performance

To understand why this composite material is so effective, we must break down the specific demands placed on an electrical connector and how glass-filled PTFE meets each one.

Unpacking Electrical Insulation

An insulator's primary job is to prevent the flow of electricity between conductive paths. PTFE is one of the best-known materials for this, possessing a very high dielectric strength.

This property is crucial for preventing short circuits and maintaining signal integrity, especially in high-frequency or high-voltage applications where lesser materials would fail. The addition of glass fibers does not significantly compromise this core electrical advantage.

The Role of Dimensional Stability

Connectors must maintain their precise shape and size to ensure a reliable connection every time. Glass-filled PTFE excels here due to two key factors.

First, it exhibits very low creep, meaning it resists deforming under sustained mechanical pressure. Second, it has a low coefficient of thermal expansion, ensuring that the connector's internal geometry remains consistent even as temperatures fluctuate. This stability guarantees that pins and sockets stay perfectly aligned.

Superior Wear Resistance for High Mating Cycles

Electrical connectors are often plugged and unplugged hundreds or thousands of times over their lifespan. This is known as high mating cycles.

Virgin PTFE is a relatively soft material that can wear down or deform with repeated use. The glass fibers act as a powerful reinforcing agent, dramatically increasing the material's hardness and durability. This allows it to withstand the friction of repeated connections without degrading.

Understanding the Trade-offs

No material choice is without its compromises. While glass-filled PTFE is an outstanding performer, it's important to be aware of its specific characteristics.

Increased Abrasiveness

The hardness provided by the glass fibers can make the material more abrasive than unfilled PTFE. When designing a connector, this must be considered in relation to the mating contact surfaces. Softer metals could potentially experience wear over many cycles.

Reduced Flexibility

The addition of glass filler makes the material significantly more rigid. While this is a primary benefit for creating a stable connector housing or insulator, it means the material is not suitable for applications that require the part to be flexible.

Chemical Resistance Nuances

PTFE is famous for its extreme chemical inertness. While glass-filled variants are still highly resistant to most chemicals, the glass fibers themselves can be attacked by a few specific substances, such as hydrofluoric acid. This is a rare consideration but critical in certain industrial environments.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary design goal.

- If your primary focus is maximum electrical performance and chemical inertness in a low-stress environment: Virgin PTFE may be sufficient, provided mechanical demands are minimal.

- If your primary focus is reliability across many connection cycles and fluctuating temperatures: Glass-filled PTFE is the superior choice for its unmatched dimensional stability and wear resistance.

- If your application involves highly sensitive or soft metal mating surfaces: You must account for the abrasiveness of glass-filled PTFE or consider alternative fillers like bronze or carbon.

By understanding this balance of properties, you can confidently specify a material that creates a connector that is both electrically sound and mechanically robust.

Summary Table:

| Property | Why It Matters for Connectors | How Glass-Filled PTFE Delivers |

|---|---|---|

| Electrical Insulation | Prevents short circuits, maintains signal integrity. | High dielectric strength of PTFE base. |

| Dimensional Stability | Ensures reliable connection over time and temperature. | Low creep and low thermal expansion from glass fibers. |

| Wear Resistance | Withstands repeated plugging/unplugging (high mating cycles). | Glass fibers reinforce the material, increasing hardness. |

Need a reliable, high-performance material for your electrical connectors?

At KINTEK, we specialize in precision manufacturing of glass-filled PTFE components, including rods and custom-machined parts for the semiconductor, medical, and industrial sectors. Our expertise ensures your connectors benefit from superior insulation, dimensional stability, and long-term durability.

Let us help you select the right material and fabricate the perfect component for your application, from prototype to high-volume production.

Contact KINTEK today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability