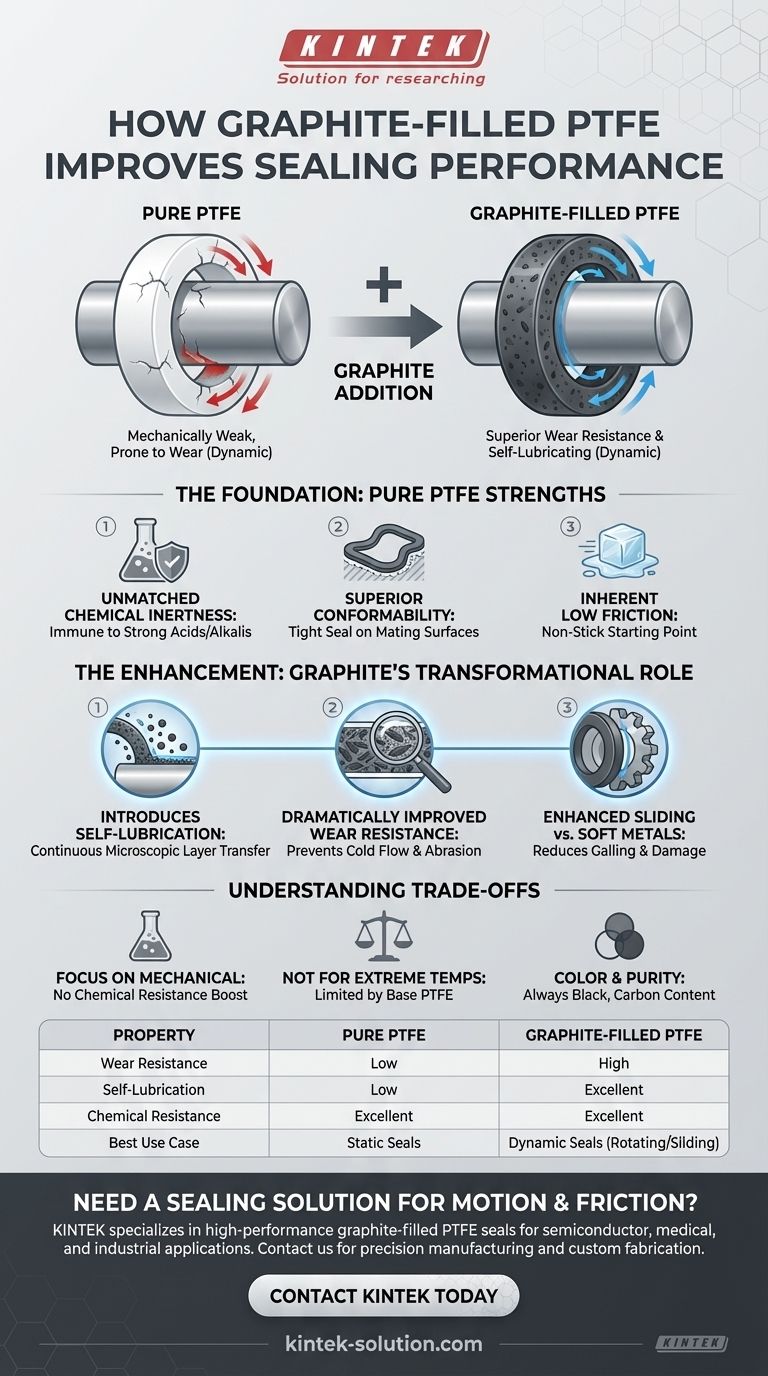

Adding graphite to Polytetrafluoroethylene (PTFE) creates a superior sealing material by fundamentally improving its wear resistance and self-lubricating properties. While pure PTFE is flexible and chemically inert, it is mechanically weak; graphite acts as a reinforcing filler that drastically reduces friction and material loss, especially in dynamic applications involving sliding or rotating parts.

While pure PTFE provides excellent chemical resistance and flexibility for a static seal, it often fails prematurely in moving applications. The addition of graphite solves this core problem by creating a self-lubricating composite that withstands wear and friction.

The Foundation: Pure PTFE's Sealing Strengths

Before understanding the enhancement, it's crucial to recognize the inherent advantages of the base material, PTFE. These properties make it a common choice for sealing in the first place.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack from strong acids, alkalis, and corrosive media. This allows it to maintain a stable, leak-free seal in the most aggressive chemical environments where other materials would quickly degrade.

Superior Conformability

PTFE is highly flexible. This allows a PTFE gasket or seal to conform perfectly to microscopic imperfections on mating surfaces, ensuring an exceptionally tight and secure initial seal without excessive clamping force.

Inherent Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This non-stick characteristic is a valuable starting point for reducing the energy required in moving systems.

The Enhancement: How Graphite Transforms Performance

Adding graphite (typically up to 25% by weight) doesn't just add a new property; it creates a synergistic effect that mitigates PTFE's primary weaknesses.

Introducing Self-Lubrication

Graphite particles act as a solid lubricant within the PTFE matrix. As the seal moves against a shaft or surface, a microscopic layer of graphite is transferred, continuously lubricating the interface. This is critical for non-lubricated systems like compressor piston rings.

Dramatically Improved Wear Resistance

This is the most significant improvement. Pure PTFE is soft and susceptible to "cold flow" (deformation under pressure) and rapid wear. The flaky structure of graphite particles provides reinforcement, preventing the PTFE from being abraded away during operation and vastly extending the seal's service life.

Enhanced Sliding Against Soft Metals

The combination of low friction and wear resistance makes graphite-filled PTFE particularly effective when sealing against softer metals like aluminum or brass. It reduces the risk of galling or damage to the metal surface.

Minor Thermal Stability Gains

While not its primary function, graphite provides a modest improvement in temperature resistance and thermal conductivity compared to pure PTFE, helping to dissipate heat from the sealing interface.

Understanding the Trade-offs

While highly effective, graphite-filled PTFE is not a universal solution. Understanding its limitations is key to proper application.

Focus on Mechanical Properties

The primary benefit of adding graphite is the improvement of mechanical properties like wear and friction. It does not significantly alter PTFE's already excellent chemical resistance. For static seals in corrosive environments with no movement, pure PTFE is often sufficient.

Not for Extreme Temperatures

While it offers a slight thermal improvement, graphite-filled PTFE is still limited by the temperature range of the base PTFE. For very high-temperature applications, other fillers like glass or carbon fiber may be more suitable.

Color and Purity

Graphite-filled PTFE is always black. In applications where color is a factor or extreme purity is required (e.g., certain food or pharmaceutical processes), the carbon content from graphite might be a consideration.

Making the Right Choice for Your Application

Selecting the correct material requires matching its properties to your primary operational challenge.

- If your primary focus is dynamic sealing (rotating or sliding parts): Graphite-filled PTFE is an excellent choice due to its superior self-lubrication and wear resistance.

- If your primary focus is sealing against soft metal surfaces: The enhanced sliding properties of graphite-filled PTFE make it a superior option to prevent wear on both the seal and the shaft.

- If your primary focus is static sealing in a harsh chemical environment: Pure PTFE may be sufficient, but graphite-filled offers better durability if vibration or frequent assembly/disassembly is expected.

By understanding the synergy between graphite's durability and PTFE's inherent strengths, you can confidently select a sealing material engineered for longevity and reliability.

Summary Table:

| Property | Pure PTFE | Graphite-Filled PTFE |

|---|---|---|

| Wear Resistance | Low | High |

| Self-Lubrication | Low | Excellent |

| Chemical Resistance | Excellent | Excellent |

| Best Use Case | Static Seals | Dynamic Seals (Rotating/Sliding) |

Need a sealing solution that lasts longer under motion and friction? KINTEK specializes in manufacturing high-performance PTFE components, including custom graphite-filled seals, liners, and labware for semiconductor, medical, laboratory, and industrial applications. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders. Contact us today to discuss how our graphite-filled PTFE seals can enhance your equipment's reliability and reduce downtime!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers