In essence, the longevity and durability of Polytetrafluoroethylene (PTFE) gaskets stem from a powerful combination of properties. They are exceptionally resistant to chemical degradation, can withstand extreme temperature ranges without failing, and possess a low-friction surface that minimizes wear over time. This makes them a highly reliable sealing solution that reduces the need for frequent replacement and lowers long-term maintenance costs.

The core reason for PTFE's durability is not a single feature, but its holistic resistance to the most common causes of gasket failure: chemical attack, temperature-induced brittleness or degradation, and physical wear. This makes it a "set and forget" solution for many demanding industrial environments.

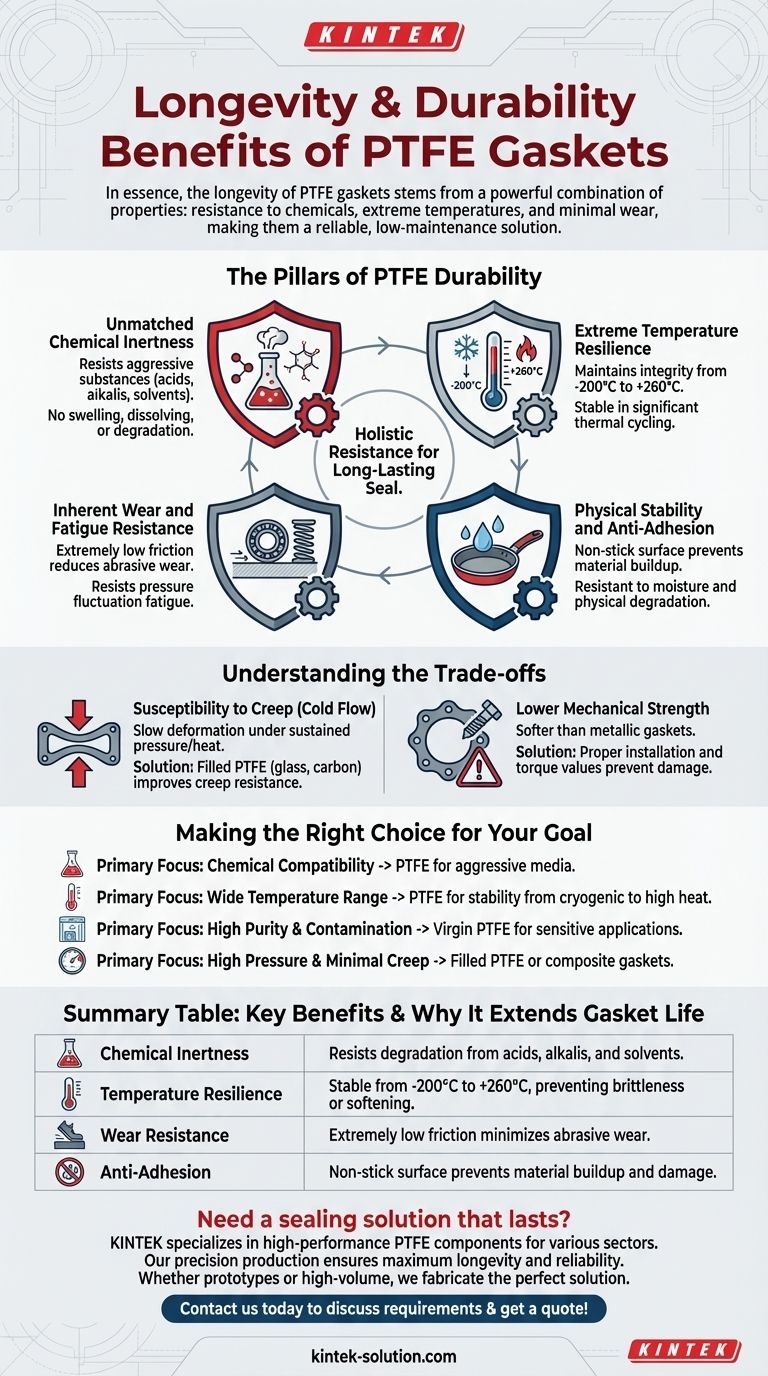

The Pillars of PTFE Durability

To truly understand why PTFE gaskets last so long, we must examine the specific properties that contribute to their resilience. These characteristics work in concert to provide a stable, long-lasting seal.

Unmatched Chemical Inertness

PTFE is one of the most chemically inert polymers known. It is virtually immune to attack from a vast range of aggressive substances, including most acids, alkalis, and solvents.

This inertness means the gasket material does not swell, dissolve, or become brittle when exposed to harsh chemicals. This prevents degradation that would otherwise compromise the seal and lead to leaks.

Extreme Temperature Resilience

PTFE gaskets maintain their integrity and sealing capability across an exceptionally wide temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

Unlike other materials that can become brittle and crack at low temperatures or soften and deform at high temperatures, PTFE remains stable. This ensures a consistent seal in applications with significant thermal cycling.

Inherent Wear and Fatigue Resistance

PTFE has an extremely low coefficient of friction, one of the lowest of any solid material. This "slipperiness" significantly reduces abrasive wear on both the gasket and the flange surfaces it seals against.

This property, combined with its resistance to fatigue from pressure fluctuations, directly extends the operational life of the entire sealed joint, not just the gasket itself.

Physical Stability and Anti-Adhesion

The surface of a PTFE gasket is non-stick, which prevents process media from adhering to it. This is critical for preventing material buildup that could interfere with the seal or cause damage during disassembly and maintenance.

Furthermore, PTFE is resistant to moisture and maintains its structural integrity under demanding industrial conditions, ensuring consistent, long-lasting performance without physical degradation.

Understanding the Trade-offs

While exceptionally durable, PTFE is not without its limitations. Acknowledging these trade-offs is key to using it effectively.

Susceptibility to Creep (Cold Flow)

Pure PTFE can be susceptible to creep, or "cold flow," where the material slowly deforms over time under sustained pressure, especially at elevated temperatures. This can lead to a loss of bolt torque and potential leaks.

For applications requiring higher mechanical stability, filled PTFE gaskets—which incorporate materials like glass, carbon, or graphite—are used to significantly improve creep resistance.

Lower Mechanical Strength

Compared to metallic or semi-metallic gaskets, PTFE is a softer material. It can be damaged by over-tightening the flange bolts or cut by sharp imperfections on the sealing surfaces.

Proper installation procedures and torque values are critical to prevent mechanical damage and ensure a durable seal.

Making the Right Choice for Your Goal

Selecting the right gasket material requires matching its properties to your primary operational challenge.

- If your primary focus is chemical compatibility: PTFE is an industry-standard choice for aggressive media where other elastomers or polymers would quickly fail.

- If your primary focus is performance across a wide temperature range: PTFE's stability from cryogenic levels to over 250°C makes it uniquely reliable for processes with extreme thermal swings.

- If your primary focus is high purity and preventing contamination: Virgin PTFE is free from contaminants and its anti-adhesion properties make it ideal for food, pharmaceutical, and electronic applications.

- If your application involves high pressure and requires minimal creep: Consider a filled PTFE or a composite gasket that leverages PTFE's strengths while mitigating its mechanical limitations.

By understanding these inherent properties and trade-offs, you can confidently specify PTFE gaskets for applications where long-term, maintenance-free performance is paramount.

Summary Table:

| Key Benefit | Why It Extends Gasket Life |

|---|---|

| Chemical Inertness | Resists degradation from acids, alkalis, and solvents. |

| Temperature Resilience | Stable from -200°C to +260°C, preventing brittleness or softening. |

| Wear Resistance | Extremely low friction minimizes abrasive wear. |

| Anti-Adhesion | Non-stick surface prevents material buildup and damage. |

Need a sealing solution that lasts?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your gaskets deliver maximum longevity and reliability, reducing downtime and maintenance costs.

Whether you need prototypes or high-volume orders, we can fabricate the perfect PTFE solution for your demanding application.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Is PTFE recommended for abrasive applications? A Guide to PTFE's Strengths and Weaknesses

- What maintenance practices extend the lifespan of PTFE expansion bellows? A Guide to Maximizing Uptime

- What are the key properties and applications of PTFE packing? Discover Its Versatility in Harsh Environments

- What types of applications are PTFE piston seals suitable for? The Ultimate Guide for Demanding Environments

- What are the standard temperature limits for PTFE Teflon O-rings? Master the -200°C to 250°C Range

- How are PTFE seals manufactured and customized? Precision CNC Machining for Superior Performance

- What are typical applications of Teflon/PTFE machined parts? Key Uses in Aerospace, Medical & Chemical Processing

- What are the characteristics of PTFE Lined Gate Valves? Ideal for Full-Bore Flow and Tight Shut-Off