At its core, Polytetrafluoroethylene (PTFE) is a high-performance thermoplastic polymer. It is uniquely suited for sealing applications due to its unparalleled chemical inertness, ability to perform across an extremely wide temperature range, and an exceptionally low coefficient of friction. These properties stem directly from its unique molecular structure.

PTFE solves sealing challenges in extreme environments where conventional materials like elastomers would quickly degrade and fail. Its value lies in its ability to maintain its integrity against aggressive chemicals, cryogenic cold, and significant heat, ensuring a reliable and long-lasting seal.

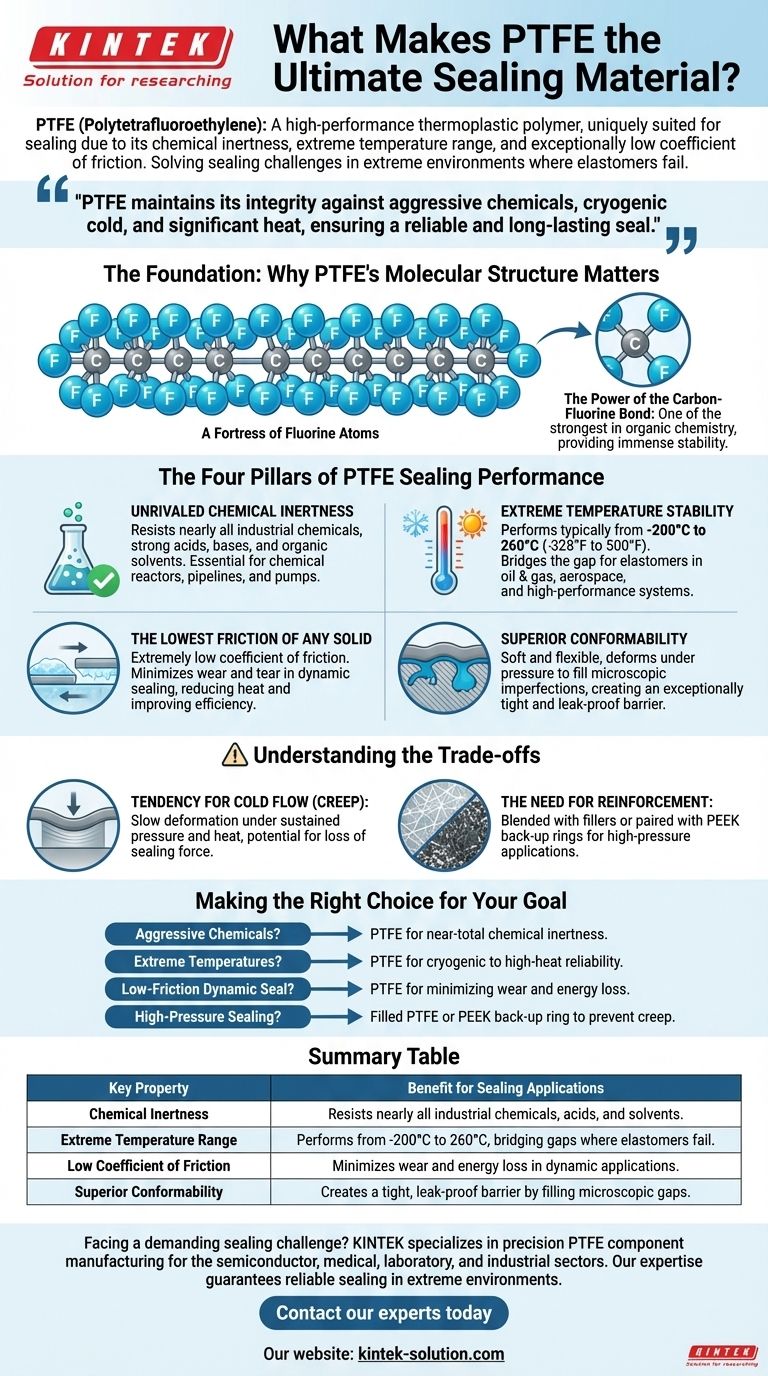

The Foundation: Why PTFE's Molecular Structure Matters

The remarkable properties of PTFE are not accidental; they are a direct result of its chemical makeup. Understanding this structure reveals why it is such a robust sealing material.

A Fortress of Fluorine Atoms

PTFE consists of a long, linear chain of carbon atoms. Crucially, each carbon atom is completely shielded by a sheath of larger fluorine atoms.

The Power of the Carbon-Fluorine Bond

The bond between the carbon and fluorine atoms is one of the strongest known in organic chemistry. This immense bond strength gives the entire molecule incredible stability, making it highly resistant to being broken apart by chemical or thermal energy.

The Pillars of PTFE Sealing Performance

This stable molecular structure translates into four key characteristics that make PTFE a premier choice for demanding sealing applications in industries from aerospace to chemical processing.

1. Unrivaled Chemical Inertness

Because of its strong, protective fluorine sheath, PTFE is one of the most non-reactive substances known. It resists attack from nearly all industrial chemicals, including strong acids, bases, and organic solvents.

This makes it an essential material for seals in chemical reactors, pipelines, and pumps where exposure to aggressive media is constant.

2. Extreme Temperature Stability

PTFE maintains its flexibility and sealing properties across a vast temperature range, typically from -200°C to 260°C (-328°F to 500°F).

It effectively bridges the gap where elastomeric seals fail due to heat or brittleness in cold, but where a full metal seal is not required or practical. This is critical for applications in oil & gas, aerospace, and high-performance automotive systems.

3. The Lowest Friction of Any Solid

PTFE has an extremely low coefficient of friction, meaning surfaces slide against it with very little resistance. This is often compared to the friction of wet ice on wet ice.

For dynamic sealing applications, such as in rotating shafts or pistons, this property minimizes wear and tear on moving parts, reduces heat generation, and improves mechanical efficiency.

4. Superior Conformability

Despite its strength, PTFE is a relatively soft and flexible material. It readily deforms under pressure to fill microscopic imperfections and gaps between mating surfaces.

This ability to conform ensures an exceptionally tight and leak-proof barrier, which is the fundamental purpose of any seal.

Understanding the Trade-offs

While its properties are exceptional, it's critical to understand the limitations of pure, unmodified PTFE to ensure proper application.

Tendency for Cold Flow (Creep)

Under sustained pressure, especially at elevated temperatures, pure PTFE has a tendency to slowly deform or "creep" over time. This can lead to a loss of sealing force and potential leakage in certain high-pressure applications.

The Need for Reinforcement

To counteract creep and improve wear resistance, PTFE is often blended with fillers like glass fiber, carbon, or bronze. For very high-pressure dynamic seals, PTFE is frequently paired with a stronger back-up ring made from a material like PEEK to provide structural support.

Making the Right Choice for Your Goal

Selecting the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is sealing aggressive chemicals: PTFE is the default choice due to its near-total chemical inertness.

- If your primary focus is extreme temperatures: PTFE provides reliable sealing in both cryogenic and high-heat environments where elastomers cannot survive.

- If your primary focus is a low-friction dynamic seal: PTFE's non-stick, low-friction surface minimizes wear and energy loss in moving systems.

- If your primary focus is high-pressure sealing: Consider a filled grade of PTFE or use it in conjunction with a PEEK back-up ring to prevent material creep.

Ultimately, PTFE's unique combination of properties makes it a powerful problem-solver for the most demanding sealing challenges.

Summary Table:

| Key Property | Benefit for Sealing Applications |

|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, acids, and solvents. |

| Extreme Temperature Range | Performs from -200°C to 260°C, bridging gaps where elastomers fail. |

| Low Coefficient of Friction | Minimizes wear and energy loss in dynamic applications. |

| Superior Conformability | Creates a tight, leak-proof barrier by filling microscopic gaps. |

Facing a demanding sealing challenge? KINTEK specializes in precision PTFE component manufacturing for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution that delivers reliability in the most extreme environments. Contact our experts today to discuss how our PTFE seals, liners, and labware can solve your specific application needs.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE often used in electric actuated butterfly valves? Achieve Reliable, Automated Flow Control

- What are the advantages of PTFE rod over other materials? Superior Chemical & Thermal Performance

- Why is it important to use high-quality PTFE packings in industrial processes? Ensure Safety and Maximize Uptime

- What factors should be considered when selecting PTFE gaskets based on their raw materials? Choose the Right Form for Your Application

- What are the benefits of PTFE with Carbon-Graphite? Achieve Superior Wear Resistance and Low Friction

- What are the desirable properties of PTFE as a sealing material? Unlock Superior Performance in Extreme Conditions

- What is PTFE and what are its key properties? Unlock Unmatched Chemical and Thermal Resistance

- How does the high cycle life of PTFE diaphragm valves benefit pharmaceutical manufacturing? Boost Uptime & Purity