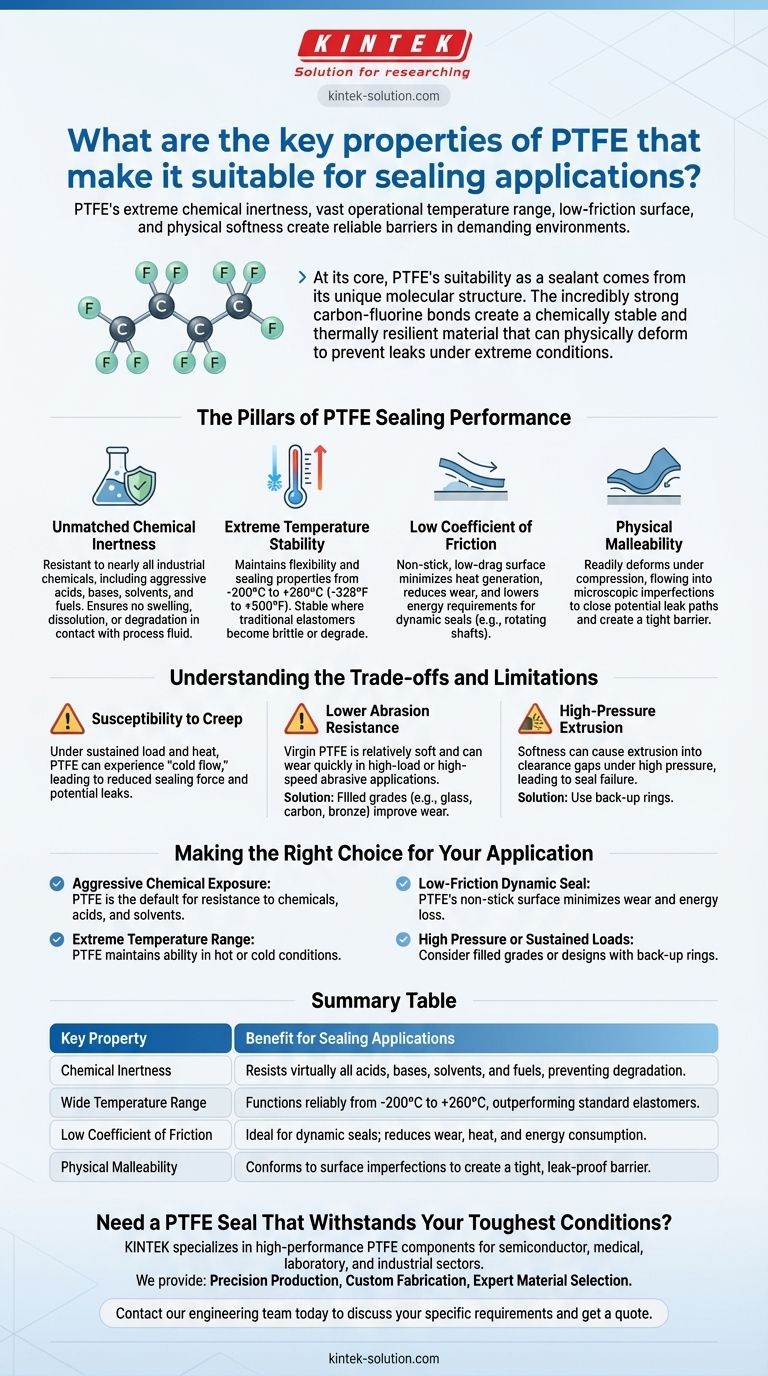

The defining properties of Polytetrafluoroethylene (PTFE) for sealing applications are its extreme chemical inertness, its vast operational temperature range, its uniquely low-friction surface, and its physical softness, which allows it to conform to irregular surfaces. This combination allows PTFE to create and maintain a reliable barrier in environments far too demanding for most other polymers.

At its core, PTFE's suitability as a sealant comes from its unique molecular structure. The incredibly strong carbon-fluorine bonds create a chemically stable and thermally resilient material that can physically deform to prevent leaks under extreme conditions.

The Pillars of PTFE Sealing Performance

To understand why PTFE is a default choice for critical sealing applications, we must examine the specific properties that directly contribute to its function. These attributes are not independent; they work together to provide a robust sealing solution.

Unmatched Chemical Inertness

The molecular structure of PTFE, a chain of carbon atoms completely shielded by fluorine atoms, makes it resistant to nearly all industrial chemicals, including aggressive acids, bases, solvents, and fuels.

This inertness is critical for a seal. It ensures the material will not swell, dissolve, or degrade when in contact with the process fluid, which would otherwise lead to seal failure and leaks.

Extreme Temperature Stability

PTFE maintains its flexibility and sealing properties across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

Where traditional elastomeric or rubber seals would become brittle and crack in cryogenic cold or soften and degrade in high heat, PTFE remains stable. This makes it essential for applications that experience significant temperature fluctuations or operate at extremes.

Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This results in a non-stick, low-drag surface.

This property is vital for dynamic seals, such as those on rotating shafts or reciprocating pistons. It minimizes heat generation, reduces wear on both the seal and the mating hardware, and lowers the energy required to operate the equipment.

Physical Malleability

Despite its durability, PTFE is a relatively soft material. It deforms readily under compression, allowing it to flow into the microscopic imperfections and tool marks present on mating hardware surfaces.

This ability to conform is the fundamental requirement of any seal. It closes potential leak paths and creates an effective, tight barrier against fluids and gases.

Understanding the Trade-offs and Limitations

No material is perfect, and a complete technical assessment requires understanding a material's limitations. While PTFE is an exceptional sealant, its primary properties introduce specific design considerations.

Susceptibility to Creep

Under sustained compressive load, especially at elevated temperatures, PTFE can exhibit "creep" or "cold flow." This is a slow, permanent deformation of the material that can reduce the sealing force over time, potentially leading to leaks.

Lower Abrasion Resistance

While its low friction reduces wear, pure, or "virgin," PTFE is a relatively soft polymer. In high-load or high-speed dynamic applications with abrasive media, it can wear more quickly than harder materials. Filled grades of PTFE (e.g., with glass, carbon, or bronze) are often used to improve wear resistance.

High-Pressure Extrusion

Because of its softness, PTFE can be forced, or "extruded," into the clearance gap between two mating parts under very high pressure. This damages the seal and leads to failure. To prevent this, PTFE seals are often used with harder, extrusion-resistant back-up rings, especially in high-pressure systems.

Making the Right Choice for Your Application

Selecting the right seal material depends entirely on the demands of your specific environment. PTFE's properties make it the clear choice for certain challenges.

- If your primary focus is aggressive chemical exposure: PTFE is the default choice, as it will not degrade when exposed to nearly all industrial chemicals, acids, and solvents.

- If your primary focus is an extreme temperature range (hot or cold): PTFE maintains its sealing ability and flexibility in conditions that would cause standard elastomers to crack or melt.

- If your primary focus is a low-friction dynamic seal: PTFE's non-stick surface minimizes wear and energy loss for rotating shafts, valve stems, and other moving components.

- If you are dealing with high pressure or sustained loads: Consider a filled grade of PTFE or a design incorporating back-up rings to mitigate the risks of creep and extrusion.

By understanding these core properties and their practical trade-offs, you can confidently specify PTFE for applications where reliability is non-negotiable.

Summary Table:

| Key Property | Benefit for Sealing Applications |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, solvents, and fuels, preventing degradation. |

| Wide Temperature Range | Functions reliably from -200°C to +260°C, outperforming standard elastomers. |

| Low Coefficient of Friction | Ideal for dynamic seals; reduces wear, heat, and energy consumption. |

| Physical Malleability | Conforms to surface imperfections to create a tight, leak-proof barrier. |

Need a PTFE Seal That Withstands Your Toughest Conditions?

KINTEK specializes in manufacturing high-performance PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. We understand that a failed seal can mean costly downtime and safety risks.

We provide:

- Precision Production: Consistent quality and reliability for critical applications.

- Custom Fabrication: From initial prototypes to high-volume production runs, tailored to your exact specifications.

- Expert Material Selection: Guidance on virgin or filled PTFE grades to optimize performance and combat challenges like creep or abrasion.

Let us help you create a leak-free, reliable solution. Contact our engineering team today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance