In the world of high-performance seals, PTFE stands out due to an unparalleled combination of properties that rarely exist together in a single material. Its extreme temperature resistance, near-total chemical inertness, and an exceptionally low coefficient of friction make it a default choice for the most demanding sealing environments where other materials would quickly degrade and fail.

Choosing a sealing material often forces a compromise between chemical, thermal, and mechanical performance. PTFE's unique value is its ability to excel across multiple extreme conditions simultaneously, though its mechanical limitations, particularly its tendency to 'creep' under pressure, must be carefully managed.

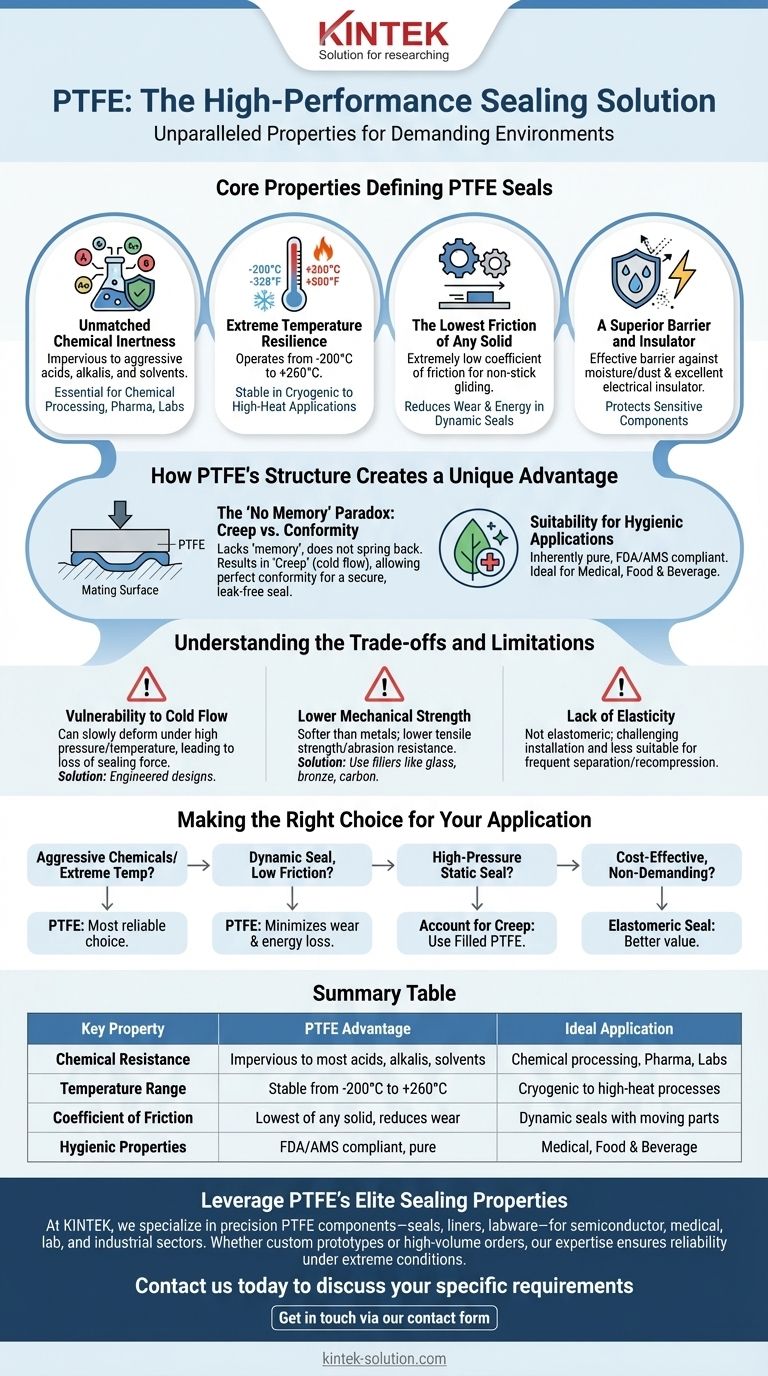

The Core Properties Defining PTFE Seals

Polytetrafluoroethylene (PTFE) is a thermoplastic, meaning it becomes moldable when heated. Its unique molecular structure gives it a set of characteristics highly desirable for creating robust, long-lasting seals.

Unmatched Chemical Inertness

PTFE is impervious to virtually all common industrial fluids and gases, including aggressive acids, alkalis, and organic solvents. This makes it an essential material for applications in chemical processing, pharmaceuticals, and laboratories.

Only a few highly reactive substances, such as molten alkaline metals and certain halogenated compounds, can degrade it.

Extreme Temperature Resilience

The material maintains its integrity across an exceptionally wide operating temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This stability allows PTFE seals to perform reliably in everything from cryogenic applications to high-heat industrial processes without becoming brittle or degrading.

The Lowest Friction of Any Solid

PTFE possesses an extremely low coefficient of friction, giving it excellent non-stick and gliding properties.

In dynamic sealing applications with moving parts, this dramatically reduces wear, heat generation, and the energy required for movement, extending the service life of both the seal and the equipment.

A Superior Barrier and Insulator

As a sealing material, PTFE provides an effective barrier against the ingress of moisture and dust, protecting sensitive components.

It is also an outstanding electrical insulator, making it a valuable choice for applications where electrical conductivity would be a problem.

How PTFE's Structure Creates a Unique Sealing Advantage

Beyond its core resistances, the physical behavior of PTFE sets it apart from traditional elastomeric (rubber-like) seals.

The 'No Memory' Paradox: Creep vs. Conformity

Unlike rubber, PTFE lacks 'memory' and does not spring back to its original shape after being compressed. This results in a phenomenon known as creep or cold flow.

While this can be a limitation, it is also a key advantage. This property allows a PTFE seal to perfectly conform to the microscopic imperfections of a mating surface, creating an exceptionally secure and leak-free seal.

Suitability for Hygienic Applications

PTFE is inherently pure and can be manufactured to conform to strict FDA and AMS requirements.

This makes it an ideal material for use in the medical, food, and beverage production industries, where preventing contamination is a critical priority.

Understanding the Trade-offs and Limitations

No material is perfect. To use PTFE effectively, it's crucial to understand its specific mechanical constraints.

Vulnerability to Cold Flow and Creep

The same property that allows PTFE to conform so well can be a drawback under high pressure or high temperature. The material can slowly and permanently deform, potentially leading to a loss of sealing force over time if the application is not designed correctly.

Lower Mechanical Strength

Compared to metals or many engineering plastics, PTFE is a relatively soft material. It has lower tensile strength and abrasion resistance, making it susceptible to damage during installation or in environments with abrasive particles.

To counteract this, PTFE can be mixed with fillers such as glass, bronze, or carbon to enhance its mechanical strength and resistance to creep.

Lack of Elasticity

Because it is not an elastomer, a PTFE seal does not have the "springiness" of a traditional rubber O-ring. This can make installation more challenging and renders it less suitable for applications that require a seal to handle frequent separation and recompression cycles.

Making the Right Choice for Your Application

Selecting PTFE requires aligning its unique profile with the primary demands of your sealing goal.

- If your primary focus is aggressive chemical exposure or extreme temperatures: PTFE is often the most reliable and sometimes only viable choice.

- If your primary focus is a dynamic seal with low friction: PTFE's non-stick properties will minimize wear and energy loss in moving systems.

- If your primary focus is a high-pressure static seal: You must account for PTFE's tendency to creep; consider using filled PTFE grades or engineered designs that physically constrain the material.

- If your primary focus is cost-effectiveness in a non-demanding environment: A standard elastomeric seal may provide better value and easier installation.

Ultimately, understanding PTFE's unique balance of elite performance and specific mechanical limitations is the key to leveraging its full potential in your design.

Summary Table:

| Key Property | PTFE Advantage | Ideal Application |

|---|---|---|

| Chemical Resistance | Impervious to most acids, alkalis, and solvents | Chemical processing, pharmaceuticals, labs |

| Temperature Range | Stable from -200°C to +260°C (-328°F to +500°F) | Cryogenic to high-heat industrial processes |

| Coefficient of Friction | Lowest of any solid, reducing wear and energy use | Dynamic seals with moving parts |

| Hygienic Properties | FDA/AMS compliant, pure and non-contaminating | Medical, food, and beverage industries |

Leverage PTFE's elite sealing properties for your most demanding applications.

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need custom prototypes or high-volume orders, our expertise ensures your seals perform reliably under extreme chemical, thermal, and dynamic conditions.

Contact us today to discuss your specific requirements: Get in touch via our contact form

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions