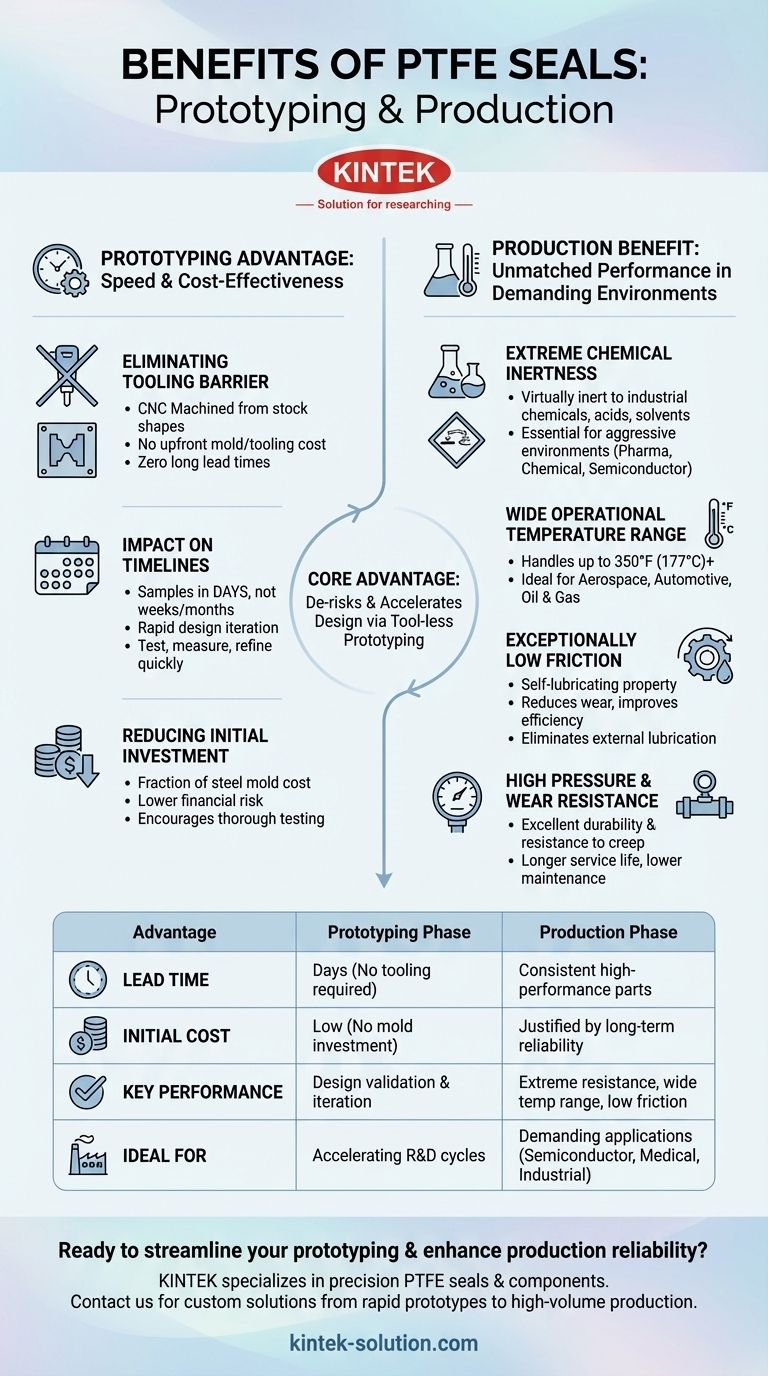

In the context of prototyping and production, the primary benefit of PTFE seals stems directly from their manufacturing process. Because they are CNC machined from solid billets or sleeves of material, they require no upfront investment in molds or tooling, making the prototyping stage exceptionally fast and cost-effective compared to traditional rubber elastomer seals. This initial advantage is then complemented by PTFE's superior material properties, which deliver extreme durability and reliability in demanding production environments.

The core advantage of PTFE lies in its dual-phase value: it significantly de-risks and accelerates the design phase through tool-less prototyping, while simultaneously offering elite performance characteristics for the final production part.

The Prototyping Advantage: Speed and Cost-Effectiveness

The initial stages of product development are often constrained by time and budget. The way PTFE seals are fabricated directly addresses these constraints, offering a clear advantage over molded alternatives.

Eliminating the Tooling Barrier

PTFE seals are machined from stock shapes of material. This subtractive manufacturing process is fundamentally different from the one used for most rubber seals, which require custom, expensive molds to be created.

This distinction is critical. The absence of a tooling requirement means there are no significant upfront costs or long lead times associated with mold design and fabrication.

The Impact on Timelines

By sidestepping the mold-making process, you can receive initial samples and prototypes in a matter of days, not the weeks or months typical for custom-molded components.

This allows for rapid design iteration. Engineers can test, measure, and refine a seal's design multiple times in the same period it would take to get a single molded prototype.

Reducing Initial Investment

The cost of a steel mold can be thousands of dollars, a significant barrier for testing new ideas. Machining a few PTFE prototypes often costs a fraction of that.

This lower financial risk encourages more thorough testing and design optimization, leading to a better final product.

The Production Benefit: Unmatched Performance in Demanding Environments

While the prototyping advantages are clear, the reason PTFE is chosen for the final product lies in its inherent material properties. These seals are engineered for applications where common elastomers would quickly fail.

Extreme Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This makes it an essential choice for aggressive environments found in the pharmaceutical, chemical processing, and semiconductor industries.

Wide Operational Temperature Range

These seals maintain their integrity and performance across an exceptionally broad temperature spectrum, easily handling continuous service temperatures up to 350°F (177°C) and higher. This makes them ideal for aerospace, automotive, and oil and gas applications.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property reduces wear on moving parts, improves operational efficiency, and eliminates the need for external lubrication.

High Pressure and Wear Resistance

When properly designed, PTFE seals exhibit excellent durability and resistance to wear and creep under high pressure. This robust performance translates to longer service life, reduced maintenance frequency, and lower long-term operating costs.

Purity and Compliance

Many grades of PTFE are FDA-compliant, making them suitable for food, beverage, and medical applications. Their inert nature ensures they will not contaminate the process media.

Understanding the Trade-offs

No material is perfect for every application. Objectivity requires acknowledging where PTFE may not be the optimal choice.

Cost at Scale

While prototyping is inexpensive, CNC machining is a slower process than injection molding. For very high-volume production of simple seals, molding an elastomer can eventually become more cost-effective on a per-unit basis if the application's performance demands are low.

Lower Elasticity

PTFE is a rigid polymer and lacks the "memory" or elasticity of rubber. It does not spring back to its original shape as readily after being compressed. This characteristic must be accounted for in the seal and hardware design, often through the use of an energizer like a spring or an O-ring.

Making the Right Choice for Your Application

Selecting the right seal material requires balancing the needs of the development cycle with the demands of the final application environment.

- If your primary focus is rapid iteration and design validation: PTFE's tool-less manufacturing makes it the ideal choice for creating quick, low-cost prototypes to perfect your design.

- If your primary focus is performance in harsh chemical or high-temperature environments: PTFE's inherent material properties provide unparalleled reliability and safety where traditional elastomers would degrade and fail.

- If your primary focus is minimizing long-term maintenance and operating costs: The durability and low-friction nature of PTFE seals reduce wear and extend service life, justifying the initial component cost.

Ultimately, choosing PTFE is a decision to invest in a material that streamlines development while delivering uncompromising performance for the entire lifecycle of your product.

Summary Table:

| Advantage | Prototyping Phase | Production Phase |

|---|---|---|

| Lead Time | Days (No tooling required) | Consistent supply of high-performance parts |

| Initial Cost | Low (No mold investment) | Justified by long-term reliability and reduced maintenance |

| Key Performance | Design validation and iteration | Extreme chemical resistance, wide temperature range, low friction |

| Ideal For | Accelerating R&D cycles | Demanding applications in semiconductor, medical, and industrial sectors |

Ready to streamline your prototyping and enhance production reliability with high-performance PTFE seals?

At KINTEK, we specialize in the precision manufacturing of PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from rapid prototypes to high-volume production runs, are designed to meet your exact specifications and demanding application requirements.

Contact us today to discuss your project and discover how our expertise can de-risk your development process and deliver uncompromising performance.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions