In demanding industries, Polytetrafluoroethylene (PTFE) seals are chosen for their unmatched resilience and reliability where other materials fail. Their primary benefits stem from an extraordinary combination of chemical inertness, the ability to withstand extreme temperatures and pressures, and an inherently low coefficient of friction. This makes them a definitive solution for ensuring operational integrity in critical applications across aerospace, chemical processing, and automotive sectors.

The core value of PTFE is not just that it resists extreme conditions, but that it solves chronic equipment failure points. By selecting PTFE, you are investing in operational stability, reducing long-term maintenance costs, and mitigating the high risks associated with seal failure in harsh environments.

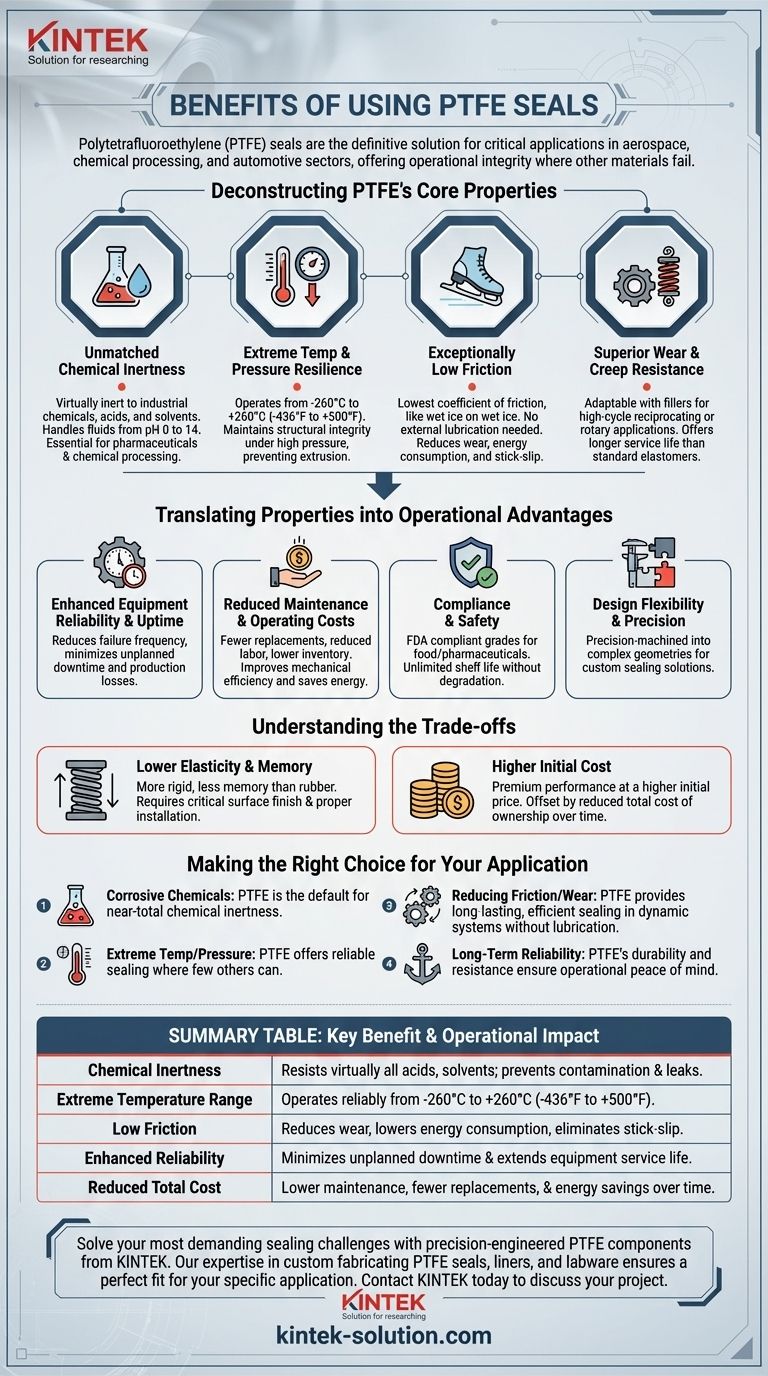

Deconstructing PTFE's Core Properties

To understand the benefits of PTFE, we must first examine the fundamental material characteristics that set it apart. These properties work in concert to deliver a level of performance that conventional elastomers cannot match.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. It can reliably handle fluids across the entire pH range from 0 to 14.

This makes it an essential material in industries like pharmaceuticals and chemical processing, where seal degradation could lead to contamination or catastrophic leaks.

Extreme Temperature and Pressure Resilience

PTFE seals operate effectively across an exceptionally wide temperature range, typically from -260°C to over 260°C (-436°F to over 500°F).

Simultaneously, they are engineered to maintain their structural integrity and sealing capability under high-pressure conditions, preventing extrusion and failure.

Exceptionally Low Friction

PTFE possesses one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This property is inherent and does not require external lubrication.

This natural lubricity significantly reduces wear and tear on moving parts, lowers energy consumption in dynamic systems, and prevents the stick-slip phenomenon common in other seal types.

Superior Wear and Creep Resistance

While basic PTFE is highly effective, it can be blended with fillers to enhance specific properties like wear and creep (the tendency to deform under constant stress) resistance.

This adaptability makes PTFE seals ideal for high-cycle reciprocating or rotary applications, where they provide a much longer service life compared to standard elastomers.

Translating Properties into Operational Advantages

These technical properties directly translate into tangible benefits that impact uptime, safety, and your bottom line. The choice of a seal material is not just a technical detail; it is a strategic decision.

Enhanced Equipment Reliability and Uptime

The durability and resistance of PTFE seals directly reduce the frequency of equipment failure. By preventing leaks in critical systems, you minimize unplanned downtime and production losses.

Reduced Maintenance and Operating Costs

A longer seal lifespan means fewer replacement cycles, reduced labor costs, and lower inventory requirements. The low-friction nature of PTFE also improves mechanical efficiency, leading to modest but consistent energy savings over the equipment's life.

Compliance and Safety

Many grades of PTFE are compliant with FDA standards, making them safe for use in food processing and pharmaceutical manufacturing. Furthermore, their unlimited shelf life means they do not degrade in storage, ensuring they are ready for service whenever needed.

Design Flexibility and Precision

PTFE can be precision-machined into complex geometries and custom designs. This allows engineers to create sealing solutions perfectly tailored to a specific application, optimizing performance where a standard off-the-shelf part would fail.

Understanding the Trade-offs

No material is a universal solution. While PTFE offers exceptional performance, it is critical to understand its limitations to ensure proper application.

Lower Elasticity and Memory

Compared to rubber elastomers, PTFE is a relatively rigid material with less "memory." It does not spring back to its original shape as effectively after being compressed.

This means surface finish and proper installation are critical. Imperfect hardware surfaces may not seal as readily, and improper handling during installation can permanently damage the seal.

Higher Initial Cost

Premium performance often comes at a higher initial price point. PTFE seals can be more expensive than their conventional rubber or urethane counterparts.

However, this cost must be weighed against the total cost of ownership. The investment often pays for itself through reduced maintenance, less downtime, and avoidance of costly failures.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material's strengths to your primary operational challenge.

- If your primary focus is handling corrosive chemicals: PTFE is the default choice due to its near-total chemical inertness, protecting both your equipment and your product.

- If your primary focus is extreme temperature or pressure: PTFE's wide operating range and structural stability make it one of the only viable options for reliable sealing in these environments.

- If your primary focus is reducing friction and wear in dynamic systems: The inherently low friction of PTFE provides a long-lasting, efficient seal for reciprocating or rotary applications without requiring lubrication.

- If your primary focus is long-term reliability in a critical system: The combination of durability, chemical resistance, and long shelf life makes PTFE an investment in operational peace of mind.

By understanding its unique properties and appropriate applications, you can leverage PTFE to solve your most difficult sealing challenges.

Summary Table:

| Key Benefit | Impact on Your Operation |

|---|---|

| Chemical Inertness | Resists virtually all acids, solvents; prevents contamination and leaks. |

| Extreme Temperature Range | Operates reliably from -260°C to +260°C (-436°F to +500°F). |

| Low Friction | Reduces wear, lowers energy consumption, eliminates stick-slip. |

| Enhanced Reliability | Minimizes unplanned downtime and extends equipment service life. |

| Reduced Total Cost | Lower maintenance, fewer replacements, and energy savings over time. |

Solve your most demanding sealing challenges with precision-engineered PTFE components from KINTEK.

Our expertise in custom fabricating PTFE seals, liners, and labware ensures a perfect fit for your specific application—whether you need prototypes or high-volume production for the semiconductor, medical, laboratory, or industrial sectors. We prioritize precision to deliver the reliability and performance your critical operations demand.

Contact KINTEK today to discuss your project and discover how our PTFE solutions can enhance your operational integrity and reduce long-term costs.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the benefits of different spring types used in PTFE seals? Optimize Sealing Performance & Lifespan

- What tests are conducted on PTFE sliding rubber bearings? Ensure Your Structure's Safety and Movement

- What types of surface treatments can be applied to PTFE bushes? Enhance Adhesion for Your Assemblies

- How is Teflon used in thermal breaks in construction? Enhance Building Energy Efficiency with PTFE

- Why is compatibility with equipment crucial when selecting PTFE packing? Avoid Costly Failures & Downtime

- What are the components of an assembly PTFE sliding bearing pad? A Guide to the Engineered System

- How do expanded PTFE gaskets compare to rubber or plastic seals in terms of lifespan? Last Up to 7x Longer

- What is a PTFE flanged bush and what are its advantages? Achieve Superior Performance in Demanding Applications