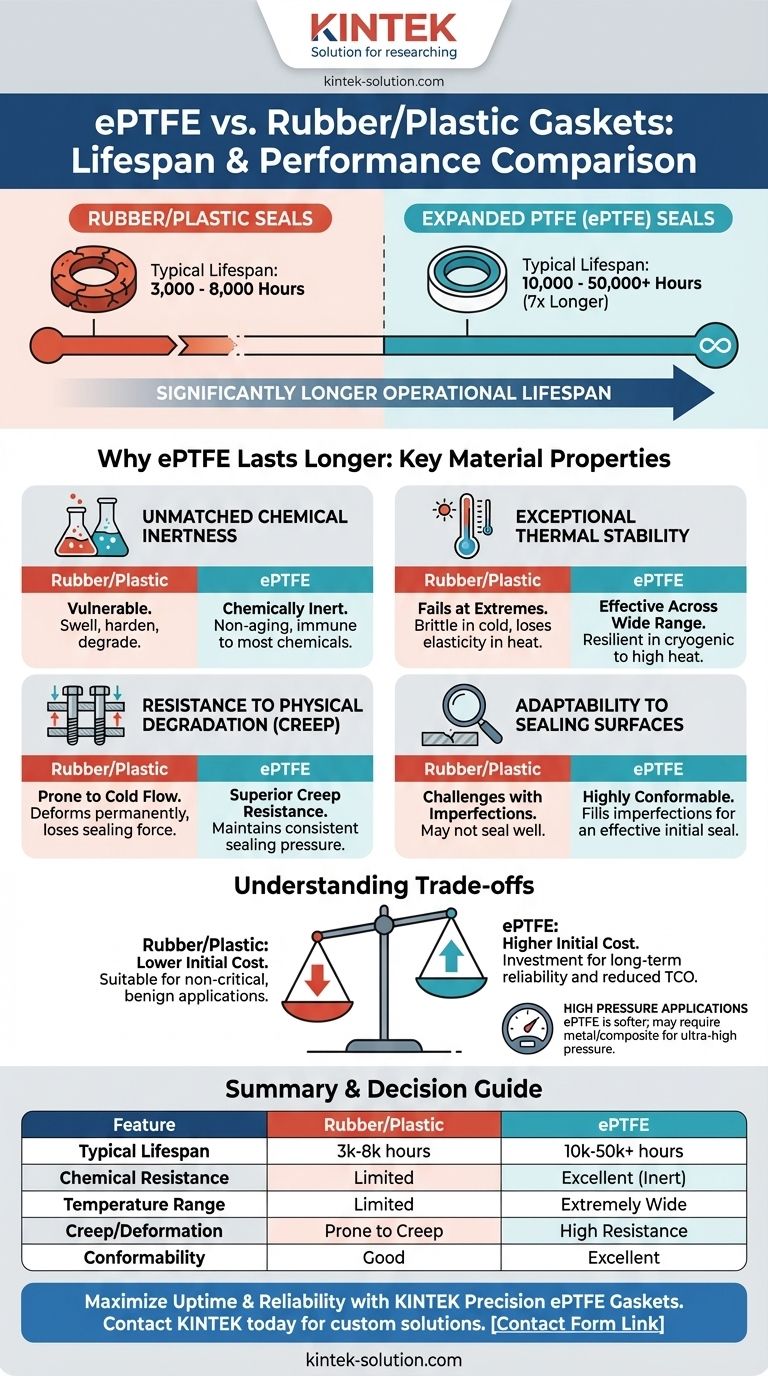

In terms of operational lifespan, expanded PTFE (ePTFE) gaskets significantly outperform their rubber or plastic counterparts, often lasting more than seven times longer under comparable conditions. While rubber seals might provide 3,000 to 8,000 hours of service, ePTFE seals can operate reliably for 10,000 to 50,000 hours, especially in demanding environments. This dramatic difference is due to ePTFE's fundamental material properties, which resist the common causes of seal failure.

The core reason for ePTFE's extended lifespan is its inherent stability. Unlike rubber or plastics, ePTFE is nearly immune to the chemical, thermal, and physical stresses that cause other materials to degrade, deform, and ultimately fail over time.

The Reasons Behind ePTFE's Superior Longevity

The extended service life of an ePTFE gasket is not a single feature but the result of several key material characteristics working in concert. Understanding these properties reveals why it maintains a reliable seal long after other materials would have failed.

Unmatched Chemical Inertness

Most polymers are susceptible to degradation from corrosive industrial fluids, causing them to swell, harden, or dissolve. Rubber and plastic seals are particularly vulnerable to chemical attack.

ePTFE, however, is chemically inert across nearly the entire pH scale. This non-aging property means it does not react with the substances it is sealing, ensuring it maintains its integrity and sealing capability indefinitely, even in the most aggressive chemical applications.

Exceptional Thermal Stability

Temperature extremes are a primary cause of gasket failure. High heat can cause rubber to break down and lose its elasticity, while extreme cold can make it brittle and prone to cracking.

ePTFE gaskets operate effectively across a vast temperature range. They remain flexible and resilient in cryogenic conditions and maintain their strength and sealing force at high temperatures, preventing leaks that would occur as other materials fail.

Resistance to Physical Degradation

Over time, gaskets are subjected to constant pressure from flange bolts. This pressure causes many materials, like rubber and some plastics, to deform permanently in a process known as creep or cold flow.

This deformation reduces the sealing pressure on the flange, leading to leaks and the need for frequent re-tightening. ePTFE exhibits superior resistance to creep, meaning it maintains its shape and continues to exert a strong, consistent sealing force throughout its service life without constant intervention.

Adaptability to Sealing Surfaces

Real-world flange surfaces are rarely perfectly flat. They can be worn, warped, or scratched, creating challenges for rigid sealing materials.

The unique structure of ePTFE makes it highly conformable. It compresses easily to fill in surface imperfections, creating an extremely effective initial seal. This adaptability prevents small leaks from the outset and contributes to a longer, more reliable service life.

Understanding the Trade-offs

While ePTFE offers a superior operational lifespan, it is critical to evaluate the complete picture. No single material is the perfect solution for every scenario.

The Factor of Initial Cost

The primary consideration when choosing against ePTFE is upfront cost. The manufacturing process for ePTFE is more complex than for conventional rubber or plastic gaskets, resulting in a higher initial purchase price.

For non-critical applications with benign conditions and easy access for replacement, a lower-cost rubber gasket can be a perfectly viable economic choice.

Application-Specific Limitations

While extremely versatile, ePTFE is a softer material. In ultra-high-pressure applications, a metal or composite gasket might be required to provide the necessary mechanical strength and blowout resistance.

It is always essential to match the gasket's pressure and temperature ratings to the specific demands of the system.

Making the Right Choice for Your Application

Selecting the correct gasket material requires balancing performance requirements with budget constraints. Your primary goal will determine the most logical choice.

- If your primary focus is minimizing upfront cost for standard applications: A conventional rubber or plastic seal is often sufficient, provided the system does not involve extreme temperatures or aggressive chemicals.

- If your primary focus is long-term reliability in harsh environments: ePTFE is the definitive choice for applications involving corrosive media, wide temperature fluctuations, or concerns about material degradation.

- If your primary focus is reducing maintenance and total cost of ownership: The superior lifespan and reliability of ePTFE significantly reduce downtime, labor for replacements, and potential losses from leaks, making it the most cost-effective solution over time.

Ultimately, choosing the right sealing material is an investment in the long-term integrity and efficiency of your operation.

Summary Table:

| Feature | Rubber/Plastic Seals | Expanded PTFE (ePTFE) Seals |

|---|---|---|

| Typical Lifespan | 3,000 - 8,000 hours | 10,000 - 50,000+ hours |

| Chemical Resistance | Limited; degrades | Excellent; chemically inert |

| Temperature Range | Limited; degrades | Extremely wide; stable |

| Creep/Deformation | Prone to cold flow | High resistance; maintains seal |

| Conformability | Good | Excellent; seals imperfect surfaces |

Maximize your system's uptime and reliability with KINTEK's precision ePTFE gaskets.

For semiconductor, medical, laboratory, and industrial applications, our expanded PTFE components are engineered for longevity in the most demanding environments. By resisting chemical attack, thermal extremes, and physical creep, our seals reduce maintenance, downtime, and total cost of ownership.

We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact KINTEK today to discuss how our ePTFE solutions can extend your seal lifespan and enhance operational efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability