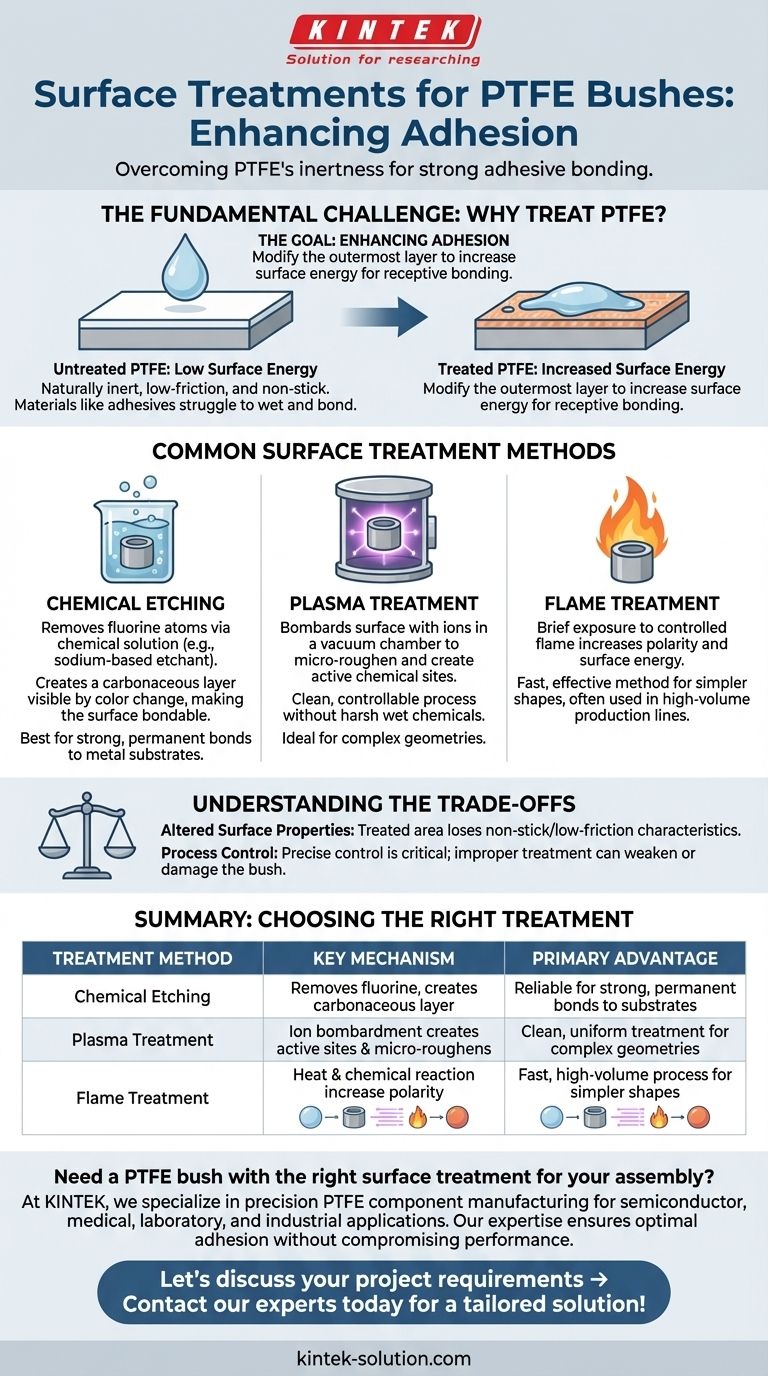

For PTFE bushes, several surface treatments are available, including chemical etching, plasma treatment, and flame treatment. These processes are specifically designed to modify the inherently non-stick, low-friction surface of PTFE to improve its ability to bond with other materials.

The core purpose of treating a PTFE bush's surface is to overcome its natural chemical inertness. These treatments increase the surface energy, making it possible to achieve strong adhesive bonds for applications where the bush must be secured to another component.

The Fundamental Challenge: Why Treat PTFE?

Polytetrafluoroethylene (PTFE) is prized for its extremely low coefficient of friction and chemical resistance. However, these same properties create a significant engineering challenge.

PTFE's Natural Inertness

The surface of untreated PTFE is "low-energy," meaning it has very weak molecular attraction. This is why materials—including adhesives—struggle to wet the surface and form a strong bond.

The Goal: Enhancing Adhesion

Surface treatments are employed to fundamentally alter the outermost layer of the PTFE. By either roughening the surface chemically or introducing reactive chemical groups, the surface energy is increased, making the bush receptive to adhesives, inks, or coatings.

Common Surface Treatment Methods

Each method modifies the PTFE surface in a distinct way to prepare it for bonding.

Chemical Etching

This is one of the most common methods. The PTFE bush is exposed to a chemical solution, often a sodium-based etchant. This process removes fluorine atoms from the polymer chain on the surface.

The result is a visible color change and a carbonaceous layer that is far more receptive to bonding than the original inert surface.

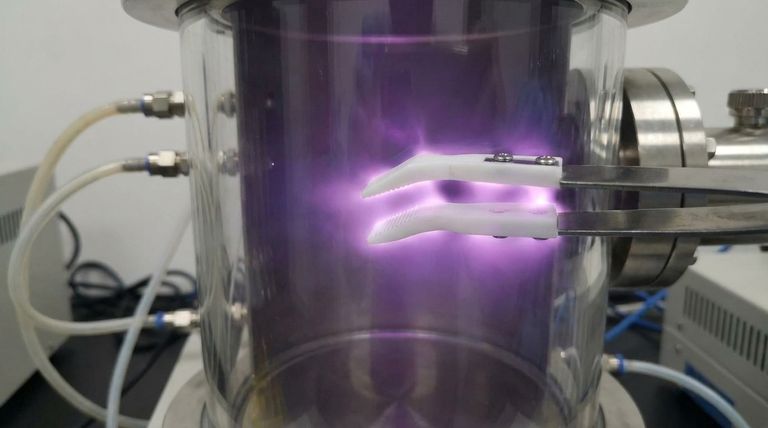

Plasma Treatment

Plasma treatment involves placing the PTFE bush in a vacuum chamber and introducing a gas, which is then energized into a plasma state.

This process bombards the surface with ions, which both micro-roughen the surface and create active chemical sites, dramatically increasing its bondability without using harsh wet chemicals.

Flame Treatment

In this method, the surface of the PTFE bush is briefly exposed to a controlled flame. The heat and chemical reaction modify the surface chemistry, increasing its polarity and surface energy.

This makes the surface more wettable and ready for adhesion, similar to the outcomes of etching and plasma treatment.

Understanding the Trade-offs

While necessary for bonding, applying a surface treatment is a critical decision with clear implications.

Altered Surface Properties

The primary trade-off is that you are intentionally changing the defining characteristic of PTFE in a localized area. The treated surface will no longer have the same non-stick or low-friction properties as the bulk material.

Process Control is Critical

Each of these treatments requires precise control. Over-etching can weaken the material, and improper plasma or flame treatment can damage the bush. These are industrial processes that add complexity and cost to the manufacturing of the final assembly.

Making the Right Choice for Your Application

Selecting a treatment depends entirely on the requirements of the final product and the manufacturing environment.

- If your primary focus is creating a strong, permanent bond to a metal substrate: Chemical etching is a reliable and well-established method for preparing the surface for structural adhesives.

- If your primary focus is avoiding wet chemicals or treating complex geometries: Plasma treatment offers a clean, highly controllable alternative that can uniformly modify intricate shapes.

- If your primary focus is a rapid, high-volume process for simpler shapes: Flame treatment can be an effective and fast method when properly integrated into a production line.

Ultimately, treating the surface of a PTFE bush transforms it from a standalone low-friction component into an integrated part of a larger assembly.

Summary Table:

| Treatment Method | Key Mechanism | Primary Advantage |

|---|---|---|

| Chemical Etching | Removes fluorine atoms, creates carbonaceous layer | Reliable for strong, permanent bonds to substrates |

| Plasma Treatment | Ion bombardment creates active sites & micro-roughens | Clean, uniform treatment for complex geometries |

| Flame Treatment | Heat & chemical reaction increase polarity | Fast, high-volume process for simpler shapes |

Need a PTFE bush with the right surface treatment for your assembly? At KINTEK, we specialize in precision PTFE component manufacturing for semiconductor, medical, laboratory, and industrial applications. Our expertise includes custom fabrication—from prototypes to high-volume orders—ensuring your PTFE bushes are treated to achieve optimal adhesion without compromising performance.

Let's discuss your project requirements → Contact our experts today for a tailored solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability