At its core, compatibility is crucial because selecting the wrong PTFE packing leads to premature failure, costly downtime, and potential safety hazards. True compatibility extends beyond just the physical dimensions; it is a meticulous process of matching the packing's material properties to the specific operational demands of your equipment, including pressure, chemical exposure, and environmental conditions.

Choosing the right PTFE packing is not about finding a generic seal, but about specifying a precise material engineered to withstand the unique stresses of its intended application. Overlooking this leads to compromised performance and reliability.

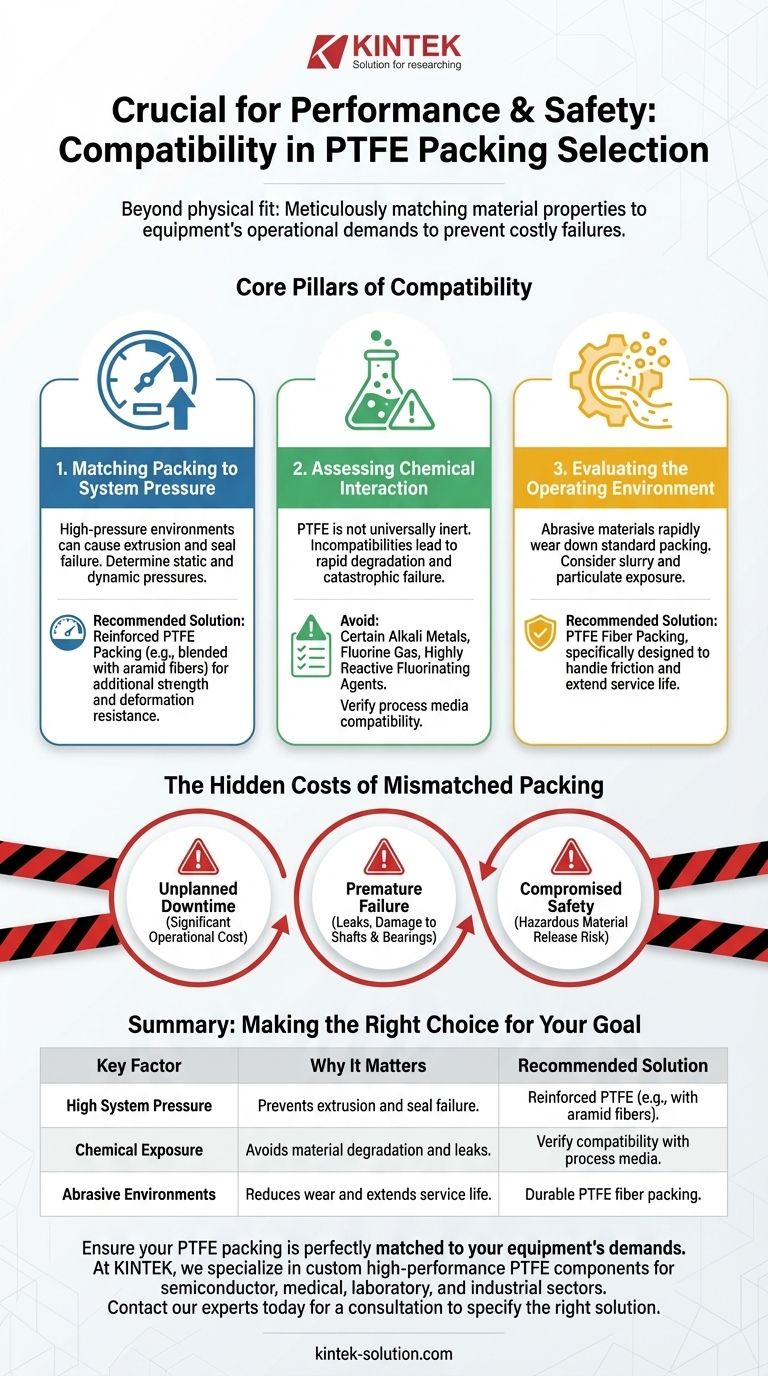

Beyond Physical Fit: The Core Pillars of Compatibility

True equipment compatibility is a multi-faceted evaluation. A packing that fits physically but fails under operational stress is an incorrect choice. Success depends on analyzing the specific demands the equipment will place on the packing material.

Matching Packing to System Pressure

Pressure is a primary force acting on any seal. High-pressure environments can physically extrude or destroy inadequate packing material, leading to immediate seal failure.

You must determine both the static and dynamic pressures within your system. Applications with high pressure often require reinforced PTFE packing, such as those blended with aramid fibers, which provide the additional strength needed to resist deformation and maintain a reliable seal.

Assessing Chemical Interaction

While PTFE is known for its excellent chemical resistance, it is not universally inert. It has known incompatibilities that can lead to rapid material degradation and catastrophic seal failure.

PTFE is vulnerable to certain alkali metals, fluorine gas, and other highly reactive fluorinating agents. Verifying that the process media is not on this short list is a critical, non-negotiable step in ensuring long-term compatibility and safety.

Evaluating the Operating Environment

The conditions surrounding the equipment can be just as damaging as the media inside it. Abrasive materials, in particular, can quickly wear down standard packing.

For equipment handling slurries or other abrasive media, a more robust option like PTFE fiber packing is often selected. Its construction is specifically designed to handle friction and wear, significantly extending its service life compared to standard variants.

The Hidden Costs of Mismatched Packing

Choosing packing based on a single factor, like chemical resistance, while ignoring others, like pressure, is a common and costly mistake. The consequences of a mismatch ripple through operations, affecting efficiency, cost, and safety.

The Risk of Unspecified Reinforcement

If you do not explicitly specify the reinforcement requirements for your application, you leave the choice to the fabrication house. They may default to their standard stock material.

This can result in a packing that is fundamentally unsuited for your equipment's pressure or abrasion demands, leading directly to premature failure.

Premature Failure and Unplanned Downtime

A mismatched packing is a seal living on borrowed time. It will wear out faster, leading to leaks that can damage equipment components like shafts and bearings.

The most significant impact is often the unplanned operational downtime required for repairs, which carries a far greater cost than the initial investment in the correct packing material.

Compromised Safety

In systems handling high pressures or aggressive chemicals, packing failure is more than an inconvenience; it is a serious safety risk. A breach can result in the uncontrolled release of hazardous materials, endangering personnel and the environment.

Making the Right Choice for Your Goal

To ensure optimal performance and safety, your selection process must be guided by your equipment's specific operational profile.

- If your primary focus is handling high pressure: Opt for a reinforced material like PTFE aramid packing to provide the necessary structural strength and prevent extrusion.

- If your primary focus is resisting abrasion: Choose a durable option like PTFE fiber packing, which is specifically designed to withstand wear from slurries or particulate matter.

- If your primary focus is chemical containment: Meticulously verify that your process media is not one of the known incompatibilities for PTFE, such as certain alkali metals or fluorine gas.

Ultimately, a systematic evaluation of these factors ensures your packing selection is a strategic decision that protects equipment integrity and operational stability.

Summary Table:

| Key Factor | Why It Matters | Recommended Solution |

|---|---|---|

| High System Pressure | Prevents extrusion and seal failure. | Reinforced PTFE (e.g., with aramid fibers). |

| Chemical Exposure | Avoids material degradation and leaks. | Verify compatibility with process media. |

| Abrasive Environments | Reduces wear and extends service life. | Durable PTFE fiber packing. |

Ensure your PTFE packing is perfectly matched to your equipment's demands.

At KINTEK, we specialize in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get a packing solution engineered for your specific pressure, chemical, and environmental requirements, maximizing performance and preventing costly downtime.

Contact our experts today for a consultation and let us help you specify the right PTFE packing for your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What modifications are made to standard PTFE to improve thermal properties? Enhance Performance with Filled PTFE

- What material grades are available for PTFE caps? Choose the Right Grade for Purity or Performance

- What are the electrical properties of PTFE balls? Unmatched Insulation for Demanding Applications

- What types of media can PTFE lined ball valves handle? Handle Corrosive Fluids Safely

- What makes PTFE gaskets suitable for aerospace applications? Unmatched Reliability in Extreme Conditions

- What are the friction characteristics of PTFE oil seals? Unlock Superior Performance with Low-Friction Seals

- What is the best PTFE material for cryogenic gas applications? mPTFE Ensures Leak-Proof Sealing

- Why are fillers added to PTFE compounds? Enhance Wear, Strength, and Performance