At their core, PTFE oil seals are defined by an exceptionally low coefficient of friction. This characteristic stems from the material's unique molecular structure, making it one of the most slippery solid materials known. This allows PTFE seals to operate with minimal resistance, even in dry or low-lubrication environments, significantly reducing wear and energy consumption.

The fundamental advantage of PTFE is its self-lubricating nature. This results in seals that generate very little friction, extending the life of both the seal and the shaft, and ensuring consistent performance even after prolonged shutdowns.

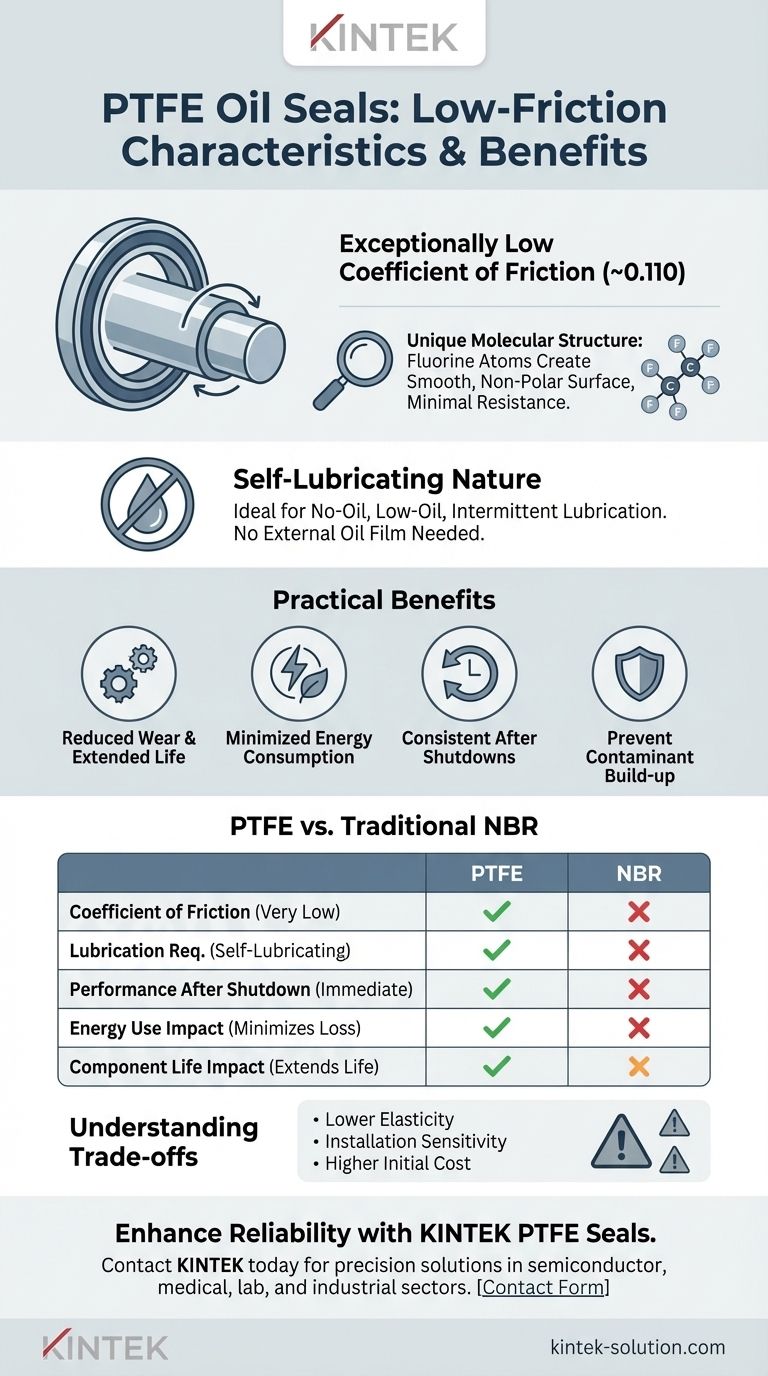

The Source of PTFE's Low-Friction Properties

The superior performance of PTFE seals is not an accident; it is a direct result of its material science. Understanding the source of these properties helps in appreciating their application benefits.

A Unique Molecular Structure

PTFE's low-friction behavior is due to its composition of carbon and fluorine atoms. The fluorine atoms create a very smooth, non-polar surface that exhibits weak intermolecular forces, allowing other materials to slide across it with minimal resistance.

The Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, with a typical value around 0.110. This is significantly lower than traditional elastomeric seals like NBR (nitrile rubber), which have moderate friction and require consistent lubrication to function properly.

Self-Lubricating Nature

The most critical outcome of its low friction is that PTFE is self-lubricating. It does not depend on an external oil film to reduce friction, making it the ideal choice for applications with no-oil, low-oil, or intermittent lubrication.

Practical Benefits in Application

Low friction is not just a technical specification; it translates directly into tangible performance advantages that solve common engineering challenges.

Reduced Wear and Extended Service Life

Less friction means less abrasive wear on both the seal lip and the rotating shaft. This directly extends the operational life of the components, reducing maintenance intervals and replacement costs.

Minimized Energy Consumption

Friction generates heat and consumes energy. By minimizing this friction, PTFE seals reduce the parasitic energy loss in a system, leading to more efficient operation and lower energy costs over time.

Consistent Performance After Shutdowns

A key advantage is that PTFE seals maintain their low-friction state even after long periods of inactivity. Upon restart, they do not exhibit the "stick-slip" phenomenon common with other materials, ensuring a smooth and immediate return to operation.

Preventing Contaminant Build-up

PTFE is also known for its non-stick properties. This characteristic helps prevent contaminants and system media from adhering to the seal lip, ensuring a clean and effective sealing surface over the long term.

Understanding the Trade-offs

While its friction characteristics are exceptional, PTFE is not the universal solution for every sealing application. Acknowledging its trade-offs is crucial for proper specification.

Lower Elasticity

Compared to rubber compounds like NBR, PTFE is a plastic and is therefore less elastic. It has less "memory" or ability to rebound, which means it may not be as forgiving in applications with significant shaft runout or misalignment.

Installation Sensitivity

The seal lip on a PTFE seal is more rigid and can be more susceptible to damage during installation if not handled correctly. Care must be taken to avoid scratching or nicking the sealing edge, as it lacks the self-healing compliance of a rubber seal.

Higher Initial Cost

PTFE seals are typically more expensive than standard NBR seals. This higher upfront cost must be weighed against the long-term benefits of extended service life, reduced energy consumption, and lower maintenance requirements.

Making the Right Choice for Your Goal

Selecting the correct seal material requires matching its properties to the specific demands of the application.

- If your primary focus is high-speed or low-lubrication environments: PTFE is the superior choice due to its self-lubricating properties and minimal heat generation.

- If your primary focus is resistance to aggressive chemicals or extreme temperatures: PTFE's inherent chemical and thermal stability makes it the most reliable option.

- If your primary focus is a standard, well-lubricated application with budget constraints: A traditional NBR seal may provide adequate performance at a lower initial cost.

Ultimately, understanding the fundamental friction characteristics of PTFE allows you to specify a seal that delivers superior reliability and efficiency in your most demanding applications.

Summary Table:

| Friction Characteristic | PTFE Seal Value/Benefit | Traditional NBR Seal Comparison |

|---|---|---|

| Coefficient of Friction | ~0.110 (Very Low) | Moderate to High |

| Lubrication Requirement | Self-Lubricating (Ideal for low/no-oil) | Requires consistent lubrication |

| Performance After Shutdown | Immediate, consistent operation (No stick-slip) | Potential for stick-slip upon restart |

| Impact on Energy Use | Minimizes parasitic energy loss | Higher energy consumption due to friction |

| Impact on Component Life | Extends seal and shaft life | Higher wear rates |

Ready to enhance your equipment's reliability and efficiency?

PTFE seals from KINTEK deliver the low-friction performance you need for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our precision-manufactured PTFE components—including seals, liners, and labware—are engineered to reduce wear, lower energy costs, and extend service life.

We specialize in custom fabrication, from prototypes to high-volume orders, ensuring a perfect fit for your unique requirements.

Contact KINTEK today to discuss your project and discover how our PTFE solutions can solve your toughest sealing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability