At its core, Polytetrafluoroethylene (PTFE) is uniquely suited for aerospace applications because it reliably maintains its sealing integrity across the extreme temperature ranges, harsh chemical environments, and high-wear conditions found in critical aircraft and spacecraft systems. Its ability to perform without degradation in both cryogenic cold and high engine heat makes it a default choice for mission-critical components.

The decision to use PTFE in aerospace is not based on a single property, but on its rare combination of thermal stability, chemical inertness, and low friction. This synergy ensures unwavering performance where system failure is not an option.

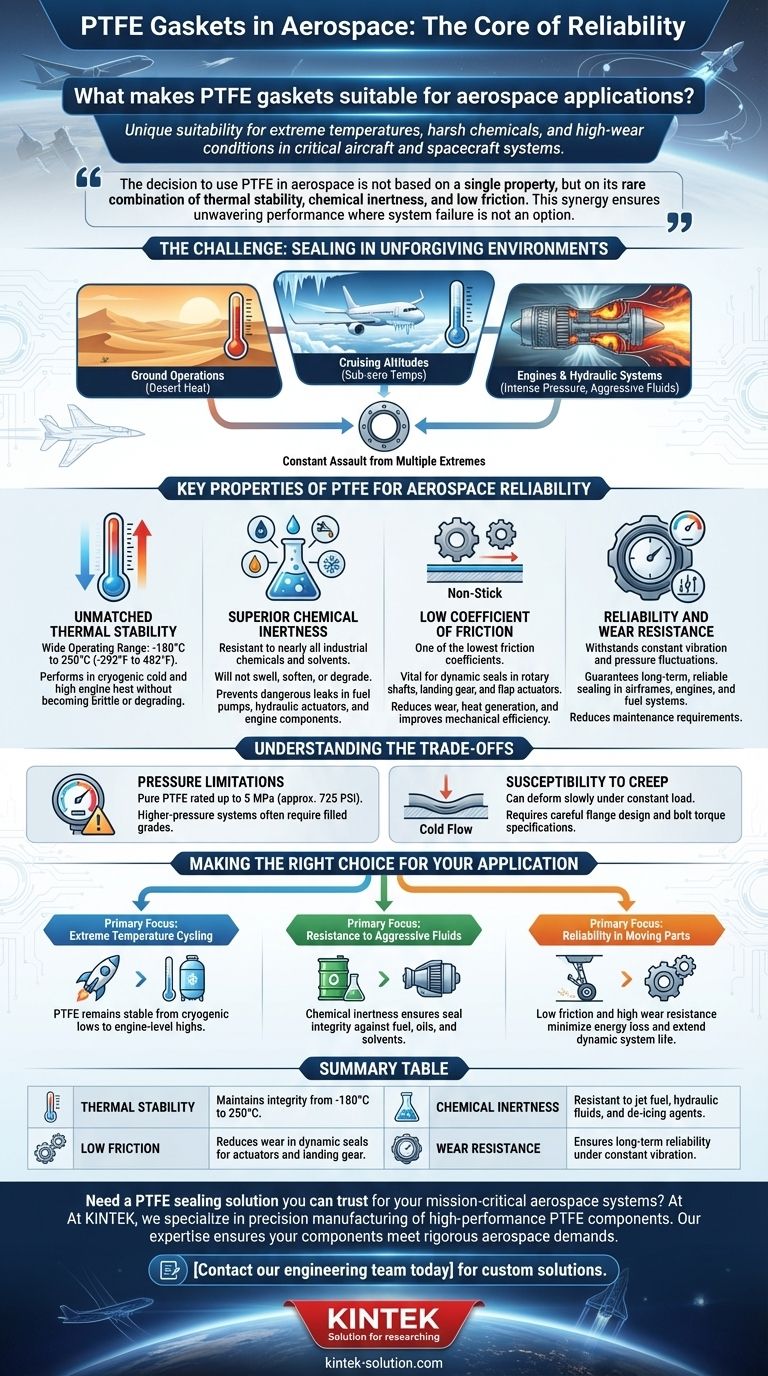

The Challenge: Sealing in Unforgiving Environments

Aerospace engineering demands materials that can withstand a constant assault from multiple environmental extremes simultaneously. A gasket or seal isn't just exposed to one challenge, but a combination of them.

These components must function flawlessly during ground operations in desert heat, at cruising altitudes with sub-zero temperatures, and within engines or hydraulic systems containing aggressive fluids and intense pressures.

Key Properties of PTFE for Aerospace Reliability

The suitability of PTFE stems directly from its molecular structure, which gives rise to several key performance characteristics. These properties directly solve the core challenges of aerospace sealing.

Unmatched Thermal Stability

PTFE gaskets exhibit an exceptionally wide operating temperature range, maintaining their mechanical strength and sealing properties from -180°C to 250°C (-292°F to 482°F).

This allows them to be used in components exposed to the cryogenic cold of space or high-altitude flight as well as the high heat generated by engines, generators, and auxiliary power units. Unlike other polymers, PTFE does not become brittle at low temperatures or degrade rapidly at high ones.

Superior Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents. This is critical in aerospace, where seals are in constant contact with aggressive substances.

It will not swell, soften, or degrade when exposed to jet fuel, hydraulic fluids, lubricants, and de-icing agents. This chemical resilience ensures the gasket maintains its shape and sealing force, preventing dangerous leaks in fuel pumps, hydraulic actuators, and engine components.

Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any solid material, giving it a non-stick quality. This is vital for dynamic seals used in moving parts.

In applications like rotary shaft seals, landing gear, and flap actuators, this low-friction surface reduces wear, minimizes heat generation, and improves mechanical efficiency. The result is a longer service life for both the seal and the components it protects.

Reliability and Wear Resistance

The material's inherent durability ensures it can withstand the constant vibration and pressure fluctuations common in aircraft systems.

This wear resistance guarantees a long-term, reliable seal in critical applications, from airframes and engines to fuel systems, reducing maintenance requirements and increasing overall system safety.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not without its limitations. Understanding these is key to its proper application.

Pressure Limitations

Pure, unmodified PTFE gaskets have moderate pressure resistance. They are typically rated for applications up to 5 MPa (approximately 725 PSI). In higher-pressure hydraulic or engine systems, filled grades of PTFE are often required to prevent deformation.

Susceptibility to Creep

Like many polymers, PTFE can be susceptible to "creep" or "cold flow," where the material slowly deforms over time under a constant load. Engineers must account for this in flange design and bolt torque specifications to ensure a long-term, effective seal is maintained.

Making the Right Choice for Your Application

Selecting a sealing material depends entirely on the primary stress it will face in its environment.

- If your primary focus is extreme temperature cycling: PTFE's ability to remain stable from cryogenic lows to engine-level highs is its standout feature.

- If your primary focus is resistance to aggressive fluids: PTFE's chemical inertness ensures seal integrity against jet fuel, hydraulic oils, and a wide range of solvents.

- If your primary focus is reliability in moving parts: PTFE's uniquely low friction and high wear resistance minimize energy loss and extend the life of dynamic systems.

Ultimately, PTFE's proven combination of properties makes it the engineering standard for sealing applications where reliability is paramount.

Summary Table:

| Key Property | Benefit for Aerospace Applications |

|---|---|

| Thermal Stability | Maintains integrity from -180°C to 250°C (-292°F to 482°F) |

| Chemical Inertness | Resistant to jet fuel, hydraulic fluids, and de-icing agents |

| Low Friction | Reduces wear in dynamic seals for actuators and landing gear |

| Wear Resistance | Ensures long-term reliability under constant vibration |

Need a PTFE sealing solution you can trust for your mission-critical aerospace systems?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom gaskets, seals, and liners. Our expertise ensures your components meet the rigorous demands of the aerospace industry, from prototypes to high-volume production.

Contact our engineering team today to discuss how we can provide a reliable, custom PTFE solution for your specific application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications