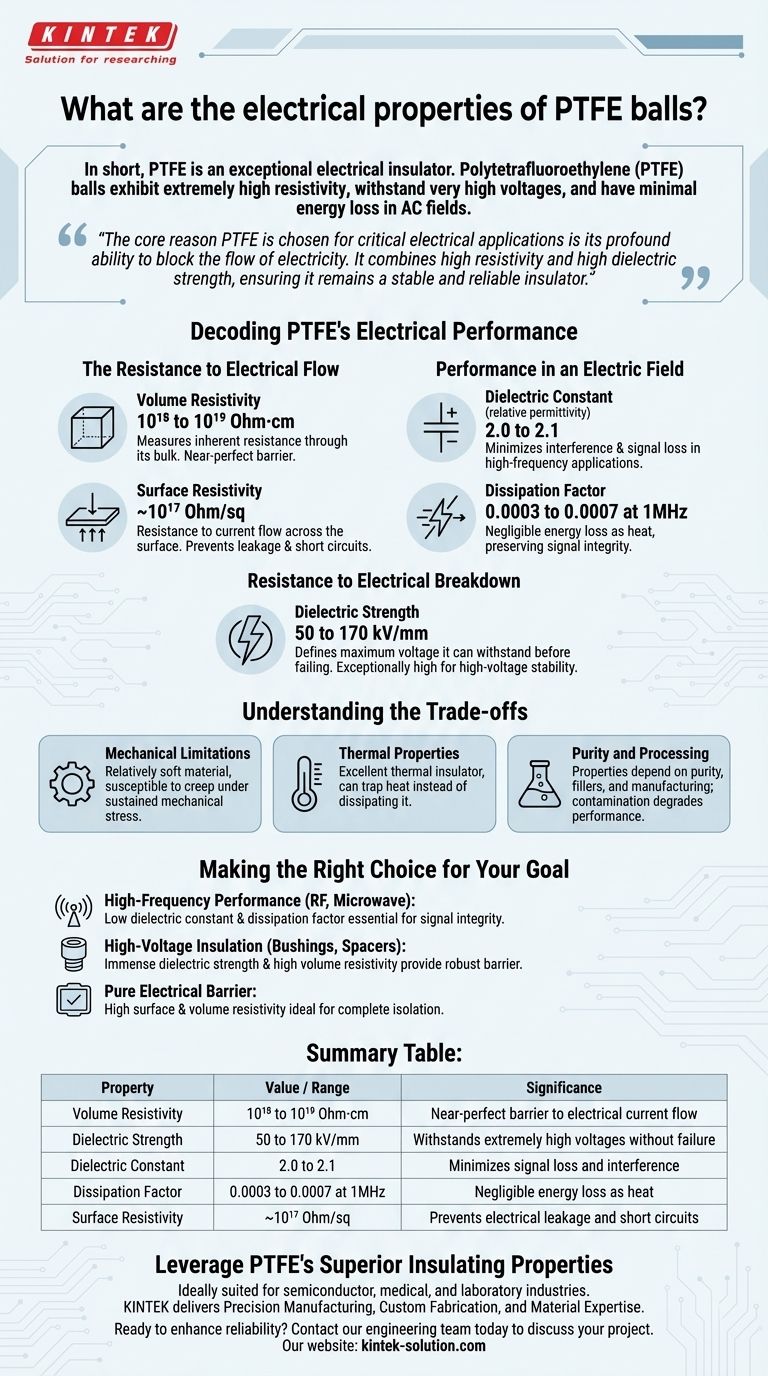

In short, PTFE is an exceptional electrical insulator. Polytetrafluoroethylene (PTFE) balls exhibit a combination of properties that make them one of the best materials for electrical insulation: extremely high resistance to electrical flow (resistivity), the ability to withstand very high voltages without breaking down (dielectric strength), and minimal energy loss in AC fields (low dielectric constant and dissipation factor).

The core reason PTFE is chosen for critical electrical applications is its profound ability to block the flow of electricity. It combines high resistivity and high dielectric strength, ensuring it remains a stable and reliable insulator even under extreme electrical stress and across a wide range of frequencies.

Decoding PTFE's Electrical Performance

To understand why PTFE is a premier insulating material, we must examine its specific electrical characteristics. Each property defines how it behaves in an electric field and contributes to its overall performance.

The Resistance to Electrical Flow

Volume Resistivity measures a material's inherent resistance to carrying an electrical current through its bulk. PTFE's volume resistivity is extraordinarily high, typically 10¹⁸ to 10¹⁹ Ohm·cm. This number signifies that it is an almost perfect barrier to electrical current.

Surface Resistivity indicates the resistance to current flow across the surface of the material. With a surface resistivity of around 10¹⁷ Ohm/sq, PTFE is highly effective at preventing electrical "leakage" along its exterior, which is critical for preventing short circuits.

Performance in an Electric Field

Dielectric Constant (also known as relative permittivity) describes a material's ability to store electrical energy when placed in an electric field. PTFE has a very low dielectric constant of 2.0 to 2.1. This is highly desirable in high-frequency applications because it minimizes interference and signal loss, ensuring the signal passes through a circuit without being stored or distorted by the insulating material.

Dissipation Factor represents the energy that is lost and converted into heat within the material when subjected to an alternating electric field. PTFE's dissipation factor is incredibly low, at 0.0003 to 0.0007 at 1MHz. This means it wastes almost no energy as heat, preserving the efficiency and integrity of high-frequency signals.

Resistance to Electrical Breakdown

Dielectric Strength is arguably one of PTFE's most important properties. It defines the maximum voltage a material can withstand before it fails and becomes conductive. PTFE has a very high dielectric strength of 50 to 170 kV/mm. This means a 1-millimeter thick sheet of PTFE can tolerate between 50,000 and 170,000 volts before breaking down, making it an extremely reliable insulator for high-voltage applications.

Understanding the Trade-offs

While PTFE's electrical properties are world-class, it's essential to consider its other characteristics to ensure it's the right choice for a given mechanical or thermal environment.

Mechanical Limitations

PTFE is a relatively soft material. It is susceptible to "creep" or cold flow, meaning it can deform over time when subjected to a constant load. This must be considered in designs where the PTFE component is under sustained mechanical stress.

Thermal Properties

PTFE is an excellent thermal insulator as well as an electrical one. This can be a disadvantage in applications where an electrical component generates heat that needs to be dissipated. The material will tend to trap heat rather than conduct it away.

Purity and Processing

The exceptional electrical values cited are for pure, virgin PTFE. The properties of the final product can be affected by fillers, additives, and the manufacturing process. Any contamination can degrade its insulating performance.

Making the Right Choice for Your Goal

PTFE's unique electrical profile makes it a definitive choice for several key applications.

- If your primary focus is high-frequency performance (e.g., RF connectors, microwave circuits): PTFE's low dielectric constant and low dissipation factor are essential for maintaining signal integrity and minimizing energy loss.

- If your primary focus is high-voltage insulation (e.g., bushings, spacers, standoffs): PTFE's immense dielectric strength and high volume resistivity provide a robust and reliable barrier against electrical breakdown.

- If your primary focus is creating a pure electrical barrier: The combination of extremely high surface and volume resistivity makes PTFE ideal for completely isolating conductive components from their surroundings.

Ultimately, PTFE's electrical properties establish it as a uniquely reliable and high-performance insulator for demanding applications.

Summary Table:

| Property | Value / Range | Significance |

|---|---|---|

| Volume Resistivity | 10¹⁸ to 10¹⁹ Ohm·cm | Near-perfect barrier to electrical current flow |

| Dielectric Strength | 50 to 170 kV/mm | Withstands extremely high voltages without failure |

| Dielectric Constant | 2.0 to 2.1 | Minimizes signal loss and interference in high-frequency circuits |

| Dissipation Factor | 0.0003 to 0.0007 at 1MHz | Negligible energy loss as heat, preserving signal integrity |

| Surface Resistivity | ~10¹⁷ Ohm/sq | Prevents electrical leakage and short circuits across the surface |

Leverage PTFE's Superior Insulating Properties

PTFE's world-class electrical performance makes it the ideal material for critical components in the semiconductor, medical, and laboratory industries. Whether your application demands high-voltage stability, high-frequency signal integrity, or pure electrical isolation, KINTEK can deliver.

We provide:

- Precision Manufacturing: Expertly crafted PTFE seals, liners, labware, and custom components.

- Custom Fabrication: Solutions tailored to your exact needs, from prototypes to high-volume production.

- Material Expertise: Guidance on selecting the right PTFE formulation for your specific electrical and mechanical environment.

Ready to enhance your product's reliability with precision PTFE components? Contact our engineering team today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing

- What are the properties of Teflon balls? Unlock Elite Chemical & Friction Resistance

- What are PTFE balls made of and what are their key properties? Unlock Superior Chemical & Thermal Performance

- What are the tolerances for PTFE balls based on size? Precision vs. Standard Grade Explained

- What are the key features of Teflon balls? Unlock Superior Performance in Demanding Environments