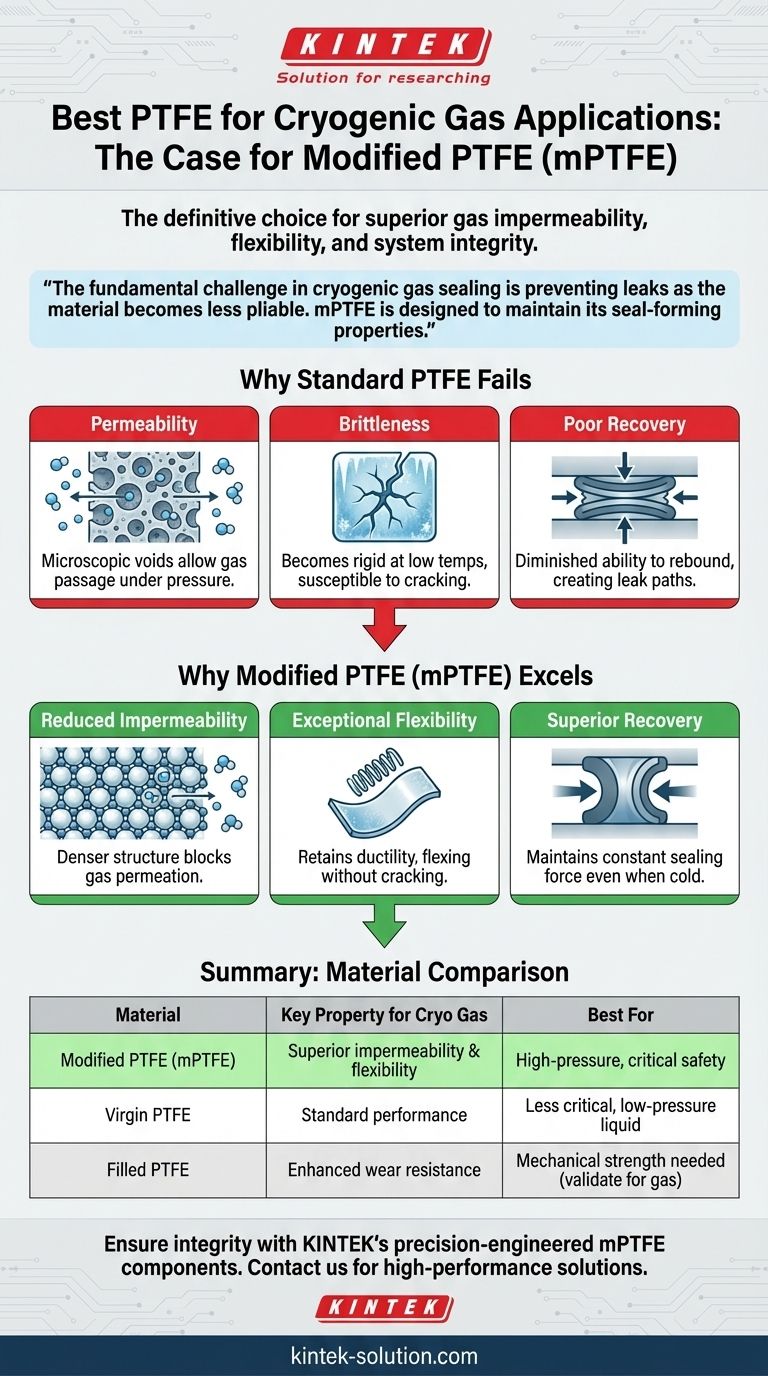

For cryogenic gas applications, the definitive material choice is Modified PTFE (mPTFE). Standard Polytetrafluoroethylene (PTFE) can become porous and brittle at extreme low temperatures, but mPTFE is specifically engineered to overcome these weaknesses. It provides vastly superior gas impermeability, flexibility, and sealability, ensuring system integrity and safety.

While several PTFE variants exist, the fundamental challenge in cryogenic gas sealing is preventing leaks as the material becomes less pliable. Modified PTFE is designed at a molecular level to maintain its seal-forming properties, making it the most reliable option for these demanding conditions.

Why Standard PTFE Is Often Insufficient

Before understanding why mPTFE excels, it's crucial to recognize the inherent limitations of standard or "virgin" PTFE when faced with the extreme cold of cryogenic gases like liquefied natural gas (LNG), nitrogen, or oxygen.

The Problem of Permeability

Even in a solid state, polymers have microscopic voids. Under the high pressures often associated with gas systems, tiny gas molecules can slowly pass directly through the material itself. This permeation is a critical failure point in cryogenic sealing.

Brittleness at Low Temperatures

As temperatures drop, standard PTFE loses its flexibility and becomes more rigid. This brittleness makes it susceptible to cracking under the mechanical stress of system pressure or vibration, leading to catastrophic seal failure.

Inadequate Flex Recovery

A seal must be able to compress to fill imperfections and then rebound to maintain sealing force. At cryogenic temperatures, standard PTFE's ability to "rebound" after being compressed is significantly diminished, which can create leak paths.

The Superior Engineering of Modified PTFE (mPTFE)

Modified PTFE is not simply PTFE with an additive; it is a chemically altered copolymer. This modification of the polymer chain structure directly addresses the failures of its predecessor.

Drastically Reduced Gas Impermeability

The altered molecular structure of mPTFE creates a denser, more tightly packed polymer matrix. This structure physically closes the microscopic voids, making it exceptionally difficult for gas molecules to permeate the material, even under high pressure.

Exceptional Low-Temperature Flexibility

mPTFE retains its ductility and flexibility far better than standard PTFE at cryogenic temperatures. This resilience prevents the material from becoming brittle, allowing it to move and flex with the system without cracking.

Superior Stretch and Flex Recovery

This material exhibits outstanding recovery after compression, even when ice-cold. It continues to push back against mating surfaces, maintaining a constant, reliable sealing force that prevents leaks as pressures and temperatures fluctuate.

Understanding the Alternatives and Their Trade-offs

While mPTFE is the ideal choice, other materials are sometimes considered. Understanding their limitations is key to avoiding costly system failures.

Virgin PTFE

This is the baseline material. It can be used in some less demanding, lower-pressure cryogenic liquid applications, but it carries a significant risk when used for high-pressure gases due to its higher permeability and tendency to become brittle.

Polymeric-Filled PTFE

These compounds add other polymers to the PTFE base to enhance properties like wear resistance or reduce cold flow. However, these fillers do not inherently improve gas impermeability and can sometimes introduce new, minor leak paths, requiring careful validation for gas service.

Pigmented PTFE

Pigments are added solely for color-coding and identification. They offer no performance benefit for cryogenic sealing and should be treated as equivalent to virgin PTFE from a performance standpoint.

Making the Right Choice for Your Goal

Ultimately, material selection must align with the safety, pressure, and criticality of your application.

- If your primary focus is maximum safety and leak prevention in high-pressure gas systems: Modified PTFE (mPTFE) is the only truly suitable choice.

- If your primary focus is a less critical, low-pressure cryogenic liquid application: Virgin PTFE may be a viable option, but you must accept a lower performance ceiling.

- If your primary focus is enhanced mechanical properties like wear resistance: A polymeric-filled PTFE might be required, but it must be rigorously specified and tested for gas permeability at your target cryogenic temperatures.

By prioritizing the unique challenges of cryogenic gas sealing, you can specify a material engineered for reliability under the most extreme conditions.

Summary Table:

| Material | Key Property for Cryogenic Gas | Best For |

|---|---|---|

| Modified PTFE (mPTFE) | Superior gas impermeability & flexibility | High-pressure gas systems, maximum safety & reliability |

| Virgin PTFE | Standard performance | Less critical, low-pressure liquid applications |

| Filled PTFE | Enhanced wear resistance | Applications needing mechanical strength (must be validated for gas) |

Ensure the integrity and safety of your cryogenic gas systems with precision-engineered mPTFE components from KINTEK.

For demanding applications in the semiconductor, medical, laboratory, and industrial sectors, our custom-fabricated mPTFE seals, liners, and labware are designed to provide leak-proof performance under extreme conditions. We specialize in creating solutions from prototypes to high-volume orders that meet your exact specifications.

Contact KINTEK today to discuss your project requirements and let our expertise in high-performance PTFE solutions bring reliability to your most critical applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Evaporating Dishes for Diverse Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some everyday uses of Teflon sheets? From Cookware to Cars, Discover Its Hidden Role

- How does chemical resistance benefit PTFE washers? Ensure Unmatched Reliability in Harsh Environments

- What industries benefit from using PTFE gaskets in ball valves? Ensure Purity & Reliability in Critical Processes

- What are the advantages of glass-filled Teflon balls? Enhanced Strength & Wear Resistance for Demanding Applications

- What are the types of PTFE fasteners and their common uses? Find the Right Solution for Your Industry

- What makes PTFE chemically resistant? The Power of Fluorine's Protective Shield

- What are the key properties that make PTFE gaskets suitable for industrial applications? | KINTEK

- How does PTFE's porous structure support medical applications? Unlocking Biocompatible Scaffolds and Filtration